advantages and disadvantage of sheet metal process Sheet metal fabrication processes are suitable for a gradual transition from prototyping to large-scale production. Making prototypes sets the baseline and expectations for larger quantities by establishing the required .

Ideal for surgical, anesthesiology, ENT, and reconstructive procedures, our Pneumatic Medical Exam Stools offer the ultimate in ergonomic performance, including foot-controlled hydraulic .

0 · sheet metal shearing process

1 · sheet metal forming disadvantages

2 · how does sheet metal form

You can contact Wilton Metal Box Company (Pvt) Ltd by phone using number 0112 614 308.

Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, .

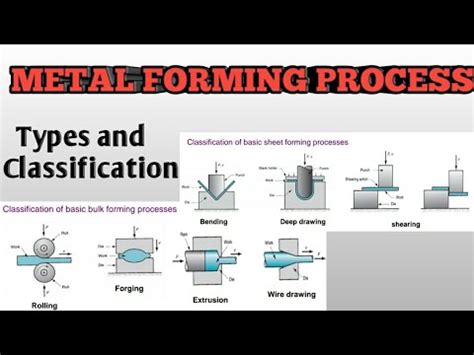

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . Advantages of Metal Forming Process. Metal forming exhibits a range of distinct advantages that contribute to its prominence in manufacturing: This process is simple and Versatile; It has an extensive Product Range; .Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to .

Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize . Sheet metal fabrication processes are suitable for a gradual transition from prototyping to large-scale production. Making prototypes sets the baseline and expectations for larger quantities by establishing the required .Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. Following are the 9 different types of sheet metal operations: It is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal .

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming, stamping, peen forming and more. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement. Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, surface quality and precision, environmental impact, and degree of automation make it a highly recommended manufacturing option. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

Advantages of Metal Forming Process. Metal forming exhibits a range of distinct advantages that contribute to its prominence in manufacturing: This process is simple and Versatile; It has an extensive Product Range; Enhanced Strength and Durability; Broad Applicability; Efficiency; Speed and Cost Savings; Diverse Material Properties; Complex . Balancing these advantages and disadvantages is crucial for selecting the appropriate application-forming process. Advantages Improved Mechanical Properties – Metal forming processes can enhance metals’ strength, toughness, and ductility due to grain refinement and work hardening during deformation.Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to the deformed material in this process. Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize yourself with both the benefits and drawbacks that it provides.

Sheet metal fabrication processes are suitable for a gradual transition from prototyping to large-scale production. Making prototypes sets the baseline and expectations for larger quantities by establishing the required infrastructure.

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. Following are the 9 different types of sheet metal operations: It is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming, stamping, peen forming and more. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.

sheet metal shearing process

Although sheet metal forming presents some challenges, its advantages in material strength, cost-effectiveness, production efficiency, variety of shapes and sizes, surface quality and precision, environmental impact, and degree of automation make it a highly recommended manufacturing option. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

Advantages of Metal Forming Process. Metal forming exhibits a range of distinct advantages that contribute to its prominence in manufacturing: This process is simple and Versatile; It has an extensive Product Range; Enhanced Strength and Durability; Broad Applicability; Efficiency; Speed and Cost Savings; Diverse Material Properties; Complex .

Balancing these advantages and disadvantages is crucial for selecting the appropriate application-forming process. Advantages Improved Mechanical Properties – Metal forming processes can enhance metals’ strength, toughness, and ductility due to grain refinement and work hardening during deformation.Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into finished goods. We apply forces such as tension, compression, shear, and others to the deformed material in this process. Sheet metal fabrication is commonly used in industrial and automotive projects due to its strength and durability. However, no production process is perfect. Before settling on a process, it’s essential to familiarize yourself with both the benefits and drawbacks that it provides.

Sheet metal fabrication processes are suitable for a gradual transition from prototyping to large-scale production. Making prototypes sets the baseline and expectations for larger quantities by establishing the required infrastructure.Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications.

sheet metal forming disadvantages

high quality sheet metal stamping part manufacturer

high quality sheet metal parts suppliers

how does sheet metal form

Winnipeg, Manitoba R3B 1M1 204-952-9773 - office 204-962-1773 - cell [email protected]

advantages and disadvantage of sheet metal process|sheet metal shearing process