7075 aluminum cnc machineable 7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms. 8 Pcs 4 Hole U-Shape Bracket for 3/4" Panels, Stamped 304 Stainless Steel Partition U Bracket, Installation Fasteners, Thickness 2.8mm

0 · Comprehensive Guide to 7075 Aluminum: Properties

1 · 7075 Aluminum: Properties, Benefits, and Uses

In our guide below, we will cover how septic tank systems work, when you need to use a metal detector to locate one, what else you need and how to find your septic tank with some easy to follow steps.

7075 aluminum alloy has good machinability, but because of the high intensity and hardness, the choice of machining methods and parameters must be well considered to avoid . 7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process . 7075 aluminum alloy has good machinability, but because of the high intensity and hardness, the choice of machining methods and parameters must be well considered to avoid defects such as tool wear, heat generation, and material distortion. . For complex geometries, 7075 aluminum can also be successfully processed using CNC machining, which .

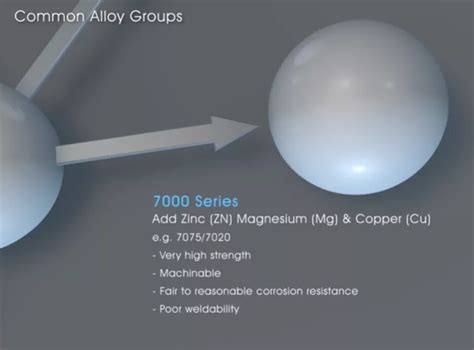

7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms.Despite its favorable properties, cnc machining Aluminum 7075 presents unique challenges: Tool Wear: High strength can accelerate tool wear. Burr Formation: Tendency to form burrs during cutting. Surface Finish: Achieving a smooth surface finish requires precise control of . 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than soft steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a tight structure and strong corrosion resistance and is best for aviation and marine plates.7075-T6's strength, light weight and machinability make it useful for CNC machined automotive parts like wheels, transmission casings, and roll cages. Reducing component weight through high-strength, lightweight 7075-T6 improves vehicle fuel efficiency.

Aluminium 7075(AlZnMgCu1,5):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical CompositionAluminum 7075-T651 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels. T651 is the temper of Aluminum 7075, and to achieve this temper, the alloy is solution heat-treated, stress relieved, and then artificially aged.D.W. Ram specializes in the production of aluminum 7075 machined parts with tight tolerances and complex geometries. We combine decades of expertise with innovative CNC machining techniques to meet client needs on time and within budget.Penta Precision's ultimate guide to aluminium 7075 machined parts covers everything from key attributes to machinability and applications to technical properties.

Aluminium 7075 Ergal is the strongest aluminum alloy. Suitable for challenging and complex applications in aerospace, marine and industrial sectors. 7075 aluminum alloy has good machinability, but because of the high intensity and hardness, the choice of machining methods and parameters must be well considered to avoid defects such as tool wear, heat generation, and material distortion. . For complex geometries, 7075 aluminum can also be successfully processed using CNC machining, which .

7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms.Despite its favorable properties, cnc machining Aluminum 7075 presents unique challenges: Tool Wear: High strength can accelerate tool wear. Burr Formation: Tendency to form burrs during cutting. Surface Finish: Achieving a smooth surface finish requires precise control of . 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than soft steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a tight structure and strong corrosion resistance and is best for aviation and marine plates.

7075-T6's strength, light weight and machinability make it useful for CNC machined automotive parts like wheels, transmission casings, and roll cages. Reducing component weight through high-strength, lightweight 7075-T6 improves vehicle fuel efficiency.Aluminium 7075(AlZnMgCu1,5):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical CompositionAluminum 7075-T651 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels. T651 is the temper of Aluminum 7075, and to achieve this temper, the alloy is solution heat-treated, stress relieved, and then artificially aged.

D.W. Ram specializes in the production of aluminum 7075 machined parts with tight tolerances and complex geometries. We combine decades of expertise with innovative CNC machining techniques to meet client needs on time and within budget.

Penta Precision's ultimate guide to aluminium 7075 machined parts covers everything from key attributes to machinability and applications to technical properties.

exterior house metal art sun

Comprehensive Guide to 7075 Aluminum: Properties

7075 Aluminum: Properties, Benefits, and Uses

$1,319.00

7075 aluminum cnc machineable|7075 Aluminum: Properties, Benefits, and Uses