sheet metal forming manufacturing processes In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies. For a detailed overview and the step-by-step method, . Can I reload steel casing boxer-primed ammo? While it is technically possible to reload steel casings, they are generally not recommended for reloading due to their reduced flexibility and durability.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

A large number of aluminum contractors are working to create screen enclosures of mostly recycled materials. Consider some of these top four reasons and more if you are interested in accessing a quality aluminum screen enclosure for your home.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . 1. The different types of sheet metal forming processes such as bending, stretching, and deep drawing. 2. The materials used in sheet metal forming, including commonly used metals, alloys, and composites. 3. The .After cutting, sheet metal components often undergo forming processes, such as bending and stamping, to shape them into three-dimensional configurations. Bending involves applying force to the sheet along specific lines, creating .

bench mounted electrical pedestal socket boxes

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies. For a detailed overview and the step-by-step method, . In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, . What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

Sheet metal forming is an essential process used in industries such as automobile construction and manufacturing. It involves shaping flat sheets of metal into three-dimensional objects. This guide explores the beginning to end . Forming components without component-specific tooling in ISMF provides a competitive alternative for economically and effectively fabricating low-volume functional sheet metal products; hence, it offers a valid manufacturing .Sheet metal forming involves a wide range of processes that manufacture parts for a vast amount of purposes, both seen and unseen. Sheet metal refers to metal that has a high surface area to volume ratio. . equipment, furniture, house .

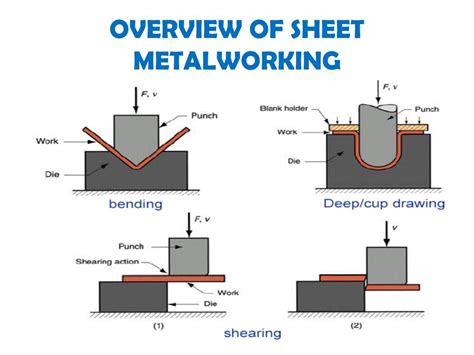

This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining.Sheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. Stamping combines cutting and forming techniques like bending, punching, embossing, and flanging to produce complex components quickly. Sheet metal forming is a manufacturing process where three dimensional parts are created by flat sheet. There are two process associated with sheet metal forming stamped and forming which are used in aerospace, automobile industries [43]. Stamped product can be curved and bend at one time whereas formed product consist of straight bends.2. Deformation . Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine.A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees.

Of these manufacturing processes, forming is a widely used process that finds applications in automotive, aerospace, defense and other industries. . They are bulk forming processes and sheet metal forming processes. Each category includes several major classes of .

Sheet Metal Forming Processes. There are a variety of core manufacturing processes used to form sheet metal into parts. The techniques deployed depend on the geometries and production volumes needed, as well as the formability of the selected metal. . Sheet metal laser cutting is a manufacturing process to cut sheet metal materials using a . BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same.Sheet metal forming is highly prevalent in manufacturing. Sheet metal parts can be discovered in a broad spectrum of applications, such as in the automotive sector, aerospace field, consumer goods, and household appliances. . Hydroforming is a specialized sheet metal forming process that utilizes high-pressure hydraulic fluid to shape the .

Welcome to the definitive guide on sheet metal processing, an essential pillar in a multitude of global industries. From our daily commute vehicles to our indispensable household appliances, countless products we interact with everyday come to life through the intricate choreography of sheet metal manufacturing processes. Sheet metal processing is a method that manipulates .

Processes – CNC Punching & Forming [email protected] 2024-06-17T20:57:48+08:00. Metal Punching & Stamping Services. . Sheet metal punching is a manufacturing process that involves using a punch and die set to create holes, shapes, or patterns in sheet metal. It is commonly used in various industries for fabrication and assembly purposes.In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. Each process brings something unique to the table—whether it’s the precision of laser and water jet cutting, the efficiency of stamping and welding, or the versatility of roll forming, .

Consistency and Reproducibility: Metal forming processes are highly controllable, which ensures consistent quality and repeatability in mass production settings. Disadvantages of Metal Forming. High Initial Costs: The tooling and setup required for many metal forming processes, such as stamping and extrusion, can be costly. These initial .Deep drawing is another widely used metal forming process. With a deep drawing, a metal sheet is clamped and placed over a cavity-shaped die. It is then punched down, which causes it to be “drawn” through the cavity — hence the . The solid granules medium sheet metal forming process uses loose particles instead of a rigid convex mold in the deep drawing process. This study focused on a mixed medium of solid granules with added graphite powder , establishing numerical models for four different proportions of graphite powder-solid granules mixtures.Sheet metal forming is a manufacturing process that uses various techniques to shape thin metal sheets into desired parts. There are a large variety of processes with subtle differences that can be used to achieve a desired shape from sheet metal. . This is a process that cuts sheet metal by applying shear stress along a straight line. The .

Typical Sheet Metal Working: Drawing Operation: (a) It is a forming process by pushing a punch against a flat sheet and forcing it into a die to take the required shape. Or in other words drawing is the operation of producing thin walled, hollow shaped parts from sheet metal. Both the die and the punch have shape of the part to be manufactured .Sheet metal manufacturing processes encompass a range of techniques aimed at shaping and forming metal sheets into desired products. In this article, we will explore some of the key processes involved in sheet metal manufacturing. 1. Cutting: The first step in sheet metal manufacturing is cutting the raw material into the desired shape and size. Stamping is a manufacturing process that involves pressing or forming sheet metal or other materials using a die and a press. This technique is used to create a wide range of components, from small intricate parts to large panels, in industries like automotive, electronics, and appliance manufacturing, due to its efficiency and precision.Explore the intricate process of sheet metal forming, its applications in various industries, and the distinction between sheet and plate metal. Learn about the manufacturing processes, the challenges with plate metal, and the final shaping of parts. . like deep drawing, there is a slight and expected change in thickness, but this may also be .

benbox cnc machine cnc 1419

of metal forming processes, as a component of the virtual manufacturing process, has a very important contribution to the reduction of the lead time. The finite element method is currently the most widely used numerical procedure for sim-ulating sheet metal forming processes. The accuracy of the simulation programs In this manuscript, we present a comprehensive overview of true digital twin applications within the manufacturing industry, specifically delving into advancements in sheet metal forming. A true digital twin is a virtual representation of a physical process or production system, enabling bidirectional data exchange between the physical and digital domains and .Metal Forming is a broad set of manufacturing techniques tha used to create metal parts or machined workpieces by converting raw materials into. . Sheet Metal Forming: It is a process where a sheet of metal is heated and then formed into its desired shape by using a tool or die. This process is often used to create display cases, brackets . This book provides essential information on metal forming, utilizing a practical distinction between bulk and sheet metal forming. In the field of bulk forming, it examines processes of cold, warm and hot bulk forming, as well as rolling and a new addition, the process of thixoforming. As for the field of sheet metal working, on the one hand it deals with sheet .

In short, roll forming involves continually feeding a long strip of metal through drum rollers to attain the desired cross-section. This process is highly efficient and cost-effective, making it the preferred choice for producing long lengths of sheet metal with consistent profiles. Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours. This operation is primarily executed using a press brake in conjunction with specialized bending dies. The process involves applying controlled force to deform the metal along a linear axis, creating permanent .

sheet metal working process pdf

benchmill 6000 cnc machining center

sheet metal stamping process pdf

sheet metal processes pdf

In this guide, I’ll compare my hands-on experience with all the most popular software across important factors like user-friendliness, compatible operating systems, range of features, customer support, and much more. Easel is one of the best CNC software for most users – especially beginners.

sheet metal forming manufacturing processes|sheet metal forming by hand