cnc machine spindle lock code M19 Orient Spindle (Optional P and R Values) P - Number of degrees (0 - 360) R - Number of degrees with two decimal places (0.00 - 360.00). M19 adjusts the spindle to a fixed position. The spindle only orients to the zero position without the optional M19 orient spindle feature. The orient spindle function allows P and R address codes. For example: $19.99

0 · spindle lock code m19

1 · m05 cnc codes

2 · cnc m30 code

3 · cnc m01 stop code

4 · cnc m codes explained

5 · cnc m code examples

6 · cnc code m00

Zenda Heating & Sheet Metal, Inc. is located at 399 Reservation Rd # J in Marina, California 93933. Zenda Heating & Sheet Metal, Inc. can be contacted via phone at (831) 392-0443 for pricing, hours and directions. Contact Info (831) 392-0443 [email protected] site;

For example all M codes and special functions which can be set by a simple switch such as MLK (machine lock) are implemented through the I/O or ladder section and are machine-tool-builder dependant, they cannot usually be set by parameter. Dive into our M-Code Cheat Sheet to understand CNC machine functions. From spindle control to tool changes, explore common and manufacturer-specific M-Codes.

Constant Spindle Speed (S = RPM) G97.1: Constant Spindle Speed (S = Surface Speed) G98: Machine Coordinates (tool tip) G98.1: Machine Coordinates: G99: Position Set Cancel: G150: Scaling OFF: G151: Scaling ON: Cincinnati M . The S code is used together with a number value to set the speed of the spindle on a CNC machine. The number value can have up to four digits and cannot have a decimal point. 100.5 is not an acceptable value to use .M19 Orient Spindle (Optional P and R Values) P - Number of degrees (0 - 360) R - Number of degrees with two decimal places (0.00 - 360.00). M19 adjusts the spindle to a fixed position. The spindle only orients to the zero position without the optional M19 orient spindle feature. The orient spindle function allows P and R address codes. For example:

I have a book with an M-Code list in it, however it is for a Haas lathe, and the numbers don't quite match what they actually do. Im lookin for either the correct code, or an eduated guess which 2 M-codes they are; as long as they are in pairs. Some machines just can't do that. On most that I've seen, an "M19" will "lock" the spindle, but softly. You can turn it a bit, and the spindle will resist you and turn back, but not very hard. On some, including the Haas I have here, "M19 P180." will orient the spindle 180° off from toolchange position.

CNC Machining . i need a g code to lock the spindle on a machining center . i have a takumi machining center with a mitsubishi controller i am looking for the code i need to lock the spindle from rotating , thanks for any help . Curt B Cast Iron. Joined Aug 16, 2007 Location . Disabled Canned Cycle on Fanuc OT Machine. Alir3za; May 15, 2024 .

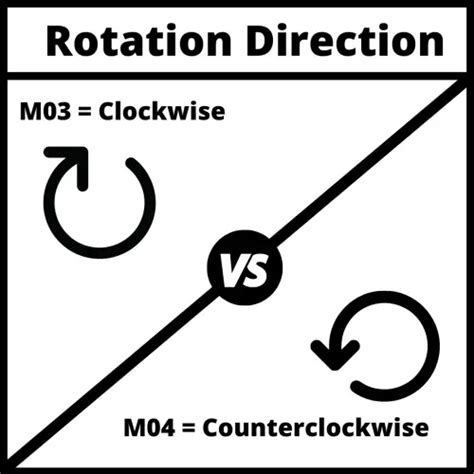

Hello I work with Mori Seiki NV 1500 DCG and Fanuc MSX-701 controller. I’d like to lock/block the spindle. Is there a command therefore? Are there any other possibilities? Thanks a lot! Alex I need to get a high speed spindle, is there a way to lock the existing spindle using g-codes to prevent the spindle from rotating? 06-12-2009, 06:32 PM #2. stevo1. View Profile View Forum Posts Gold Member Join Date Jun 2008 Posts . Gorilla CNC Machines; K2CNC; Larken; Omni CNC; Multicam Machines; Roctech CNC Routers; Shopsabre; Techno CNC . The spindle control g-codes control when the spindle is spinning and which direction it spins: M03: Start spindle spinning clockwise. M04: Start spindle spinning anti-clockwise. M05: Stop spindle spinning. Use the S word to control how many rpms the spindle turns at. Most M03 and M04 g-codes are issued right after the S word establishes the rpm.

Just looking for the unlock code for an Okuma milling machine OSP 100M I know M19 Locks the spindle, and have tried M18,M20 to unlock neither worked. A . no special M code for spindle unlock. There is "unlock" button for manual operation. Machine Reset unlocks also. . CNCzone.com-CNC Machines, CadCam ,Classifieds, Metalworking,Woodworking .

You can't on basic machines M19 rotates and locks the spindle in a pre-defined orientation ready for toolchange. M5 will release the orientation, enabling you to turn the spindle by hand M19 stated again without any manual movement will only lock the orietation in the same place ( no rotation of the spindle ) M19 stated after turning the spindle by hand will allow the . warmly welcome Machine lathe on FANUC OTD I have to use handle for rod. but when am using G1 code without spindle rotation the machine not move. I use this program: M10 chuck clamp M19 spindle orient M11 chuck unclamp G1 Z 50.0 F200.0 Dive into our M-Code Cheat Sheet to understand CNC machine functions. From spindle control to tool changes, explore common and manufacturer-specific M-Codes. . or “miscellaneous codes,” are used to control various machine functions. The specific M-Codes available can vary greatly from one CNC machine to another and are often manufacturer .Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series

The lever on top is the spindle brake/lock (for changing tools) the "quill lock" is the small lever to the right of the spindle adjacent to the bottom of the scale/ruler. If the plunge lever on the right side is difficult to raise or lower the Quill lock is .

The webpage provides a comprehensive guide on M-Codes for Haas Automation Inc. mills. I would like to know if I can lock the spindle on a TL-1 so that I can open tha jaws with one hand and hold the stock with the other? Should be simple but I am a CNC lathe newby. . By biomed_eng in forum DIY CNC Router Table Machines Replies: 14 Last Post: 01-06-2012, 07:15 AM. . code is On; HTML code is Off; how to lock spindle with an M19 to keyway stab ? . Gorilla CNC Machines; K2CNC; Larken; Omni CNC; Multicam Machines; Roctech CNC Routers; Shopsabre; Techno CNC; XYZ Gantry Routers; . code is On; code is On; HTML code is Off; Forum Rules. All times are GMT +1. The time now is 06:04 PM.

Dear Sirs In MDI/Auto mode, only in case of one particular tool, when spindle speed is more than 1500 rpm, we find Load on spindle (L) as seen at the bottom of position screen to be shooting upto 164%(although tool is running on load ie not in touch with job) and hence trips with alarm 9031, we dont have this problem in case of any other tools even at 2000 .

Haas Delivered Price. This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer.

If no M code is available you can orientate the spindle to lock it in position, then start it again but at 0 RPM. For example:M19; M03S0 ; L A T HE BRO A C HI N G : The same codes apply for orientating the spindle in the lathe as above. The FEED alarm will not be generated in the lathe however. We still need to feed while the spindle is off.You're correct, an M19 should orient the spindle (to it's toolchange position; not applicable on a lathe) and lock the spindle brake. Of course, some cheaper machines don't have brakes or position sensors on the spindle, so an M19 won't work on those machines. Though I would think that a hardinge would. I own an old Wade 98 turret lathe (22J collet) and the spindle gets warm after 3 minutes of running at max speed. ~2400 RPM. I've been thinking the spindle bearings need attention, but I'm not sure. One VMC (30 taper 8K RPM) operators manual I have lists max acceptable spindle temp rise of.

The M19 code is used to orient the spindle to a fixed position. This command leaves the spindle in that position and locked by a pin. The next spindle motion command (snnn, M3, M4, M41 or M42) will release the pin and unlock .M stands for ‘Machine codes’. This code is used for non-geometry machine functions like coolant on/off, spindle speed, tool change, pallet change etc. List of Miscellaneous functions (M codes) Sl no Functions M00 Program stop M01 Optional stop M02 Program end M03 Spindle clockwise direction M04 Spindle counter clockwise direction M05 . M Codes List. Here is a list of common M codes. Take note that although most M codes are universal, these specific M codes are what you will find on a Haas machine, and your specific machine may vary some: M00 PROGRAM STOP. M01 OPTIONAL PROGRAM STOP. M02 PROGRAM END. M03 SPINDLE ON FORWARD (S) M04 SPINDLE ON REVERSE (S) .

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

spindle lock code m19

cnc machining in los angeles

cnc machining lamp part

Lunch Bag for Adult and Kids, Insulated Lunch Box Container with Detachable Handle for Work School Travel, Cute Reusable Thermal Lunch Tote Cooler Bag with Side Pocket for Teen Boys Gamer (Game) 4.4 out of 5 stars

cnc machine spindle lock code|m05 cnc codes