cnc machine lab report It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension . We have a number of clients who are being given 1099R's that have the Line 2b Total Distribution box checked, when in fact they did not receive a "Total Distribution". Is this something that would require an amendment if a "Corrected" 1099R were given?

0 · lab report on cnc machine

1 · cnc report pdf

2 · cnc machine report

3 · cnc lab report pdf

Metal conduit does not require a grounding conductor and the box is grounded by the conduit itself. Type AC cable does not have a grounding conductor and is grounded via the metal sheath and the bonding strip.

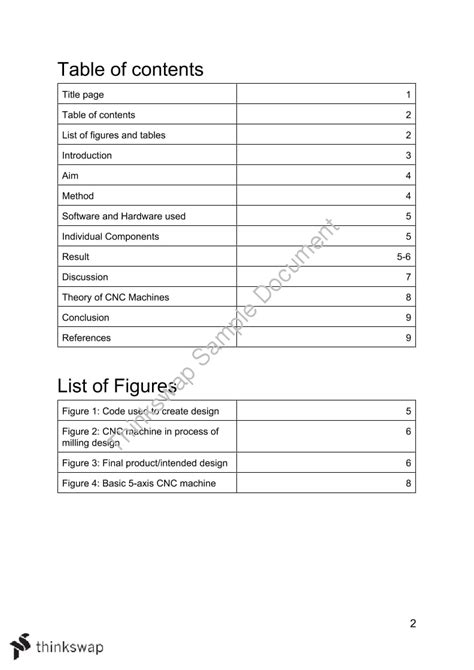

The document discusses CNC milling objectives, introduction, apparatus, safety procedures, and experimental procedures. The objectives are to understand CNC development and NC code .

This document provides details on performing various operations on a CNC .This document summarizes a CNC lab visit and provides information about .It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension .

It describes how CNC machines evolved from early numerical control machines run by punched cards to modern CNC machines with onboard computers. The document also covers CNC part programs, basic CNC .In this experiment, we are learnt how does a CNC machine works and to interpret the G- codes. G-code is the command system for the CNC (Computer Numerical Code) Machine. G- codes are any word in a CNC program that begins with the .This document provides details on performing various operations on a CNC machine, including drilling, profiling, and pocketing. It outlines the experimental setup, procedures, sample G-code programs, and results.To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC .

To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC sequence, cycle time, and .After this lab, I can understand the G-code and know what its movement in the CNC machine will be. It is a useful and efficient way for engineers to use CNC machine to make a large number of parts in less time.This document summarizes a CNC lab visit and provides information about programming a given part. It describes the machine specifications, how to set up the machine, and how to enter programs. It also discusses simulating .

OBJECTIVE: The objective of this lab is to learn the basics of the bench mill machining and CNC programming, and also to be able to manually program and machine the assigned part in the Benchmill 6000.The document discusses CNC milling objectives, introduction, apparatus, safety procedures, and experimental procedures. The objectives are to understand CNC development and NC code fundamentals, and to produce a product using CNC machinery.It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension Specimen. It describes how CNC machines evolved from early numerical control machines run by punched cards to modern CNC machines with onboard computers. The document also covers CNC part programs, basic CNC machine components, motion control types, advantages like precision and disadvantages like higher costs compared to manual machines.

In this experiment, we are learnt how does a CNC machine works and to interpret the G- codes. G-code is the command system for the CNC (Computer Numerical Code) Machine. G- codes are any word in a CNC program that begins with the letter G. Generally it is a code that tells the machine tool to perform specific actions.

This document provides details on performing various operations on a CNC machine, including drilling, profiling, and pocketing. It outlines the experimental setup, procedures, sample G-code programs, and results.To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC sequence, cycle time, and manuscript for part P-34, 4) simulate the g-code written for P-34 on the CNC simulators, 5) write the CNC sequence, cycle time, and manuscript for the tension specimen. To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC sequence, cycle time, and manuscript for part P-34, 4) simulate the g-code written for P-34 on the CNC simulators, 5) write the CNC sequence, cycle time, and manuscript for the tension specimen.

lab report on cnc machine

After this lab, I can understand the G-code and know what its movement in the CNC machine will be. It is a useful and efficient way for engineers to use CNC machine to make a large number of parts in less time.This document summarizes a CNC lab visit and provides information about programming a given part. It describes the machine specifications, how to set up the machine, and how to enter programs. It also discusses simulating programs before running them on a CNC machine.

OBJECTIVE: The objective of this lab is to learn the basics of the bench mill machining and CNC programming, and also to be able to manually program and machine the assigned part in the Benchmill 6000.

The document discusses CNC milling objectives, introduction, apparatus, safety procedures, and experimental procedures. The objectives are to understand CNC development and NC code fundamentals, and to produce a product using CNC machinery.It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension Specimen. It describes how CNC machines evolved from early numerical control machines run by punched cards to modern CNC machines with onboard computers. The document also covers CNC part programs, basic CNC machine components, motion control types, advantages like precision and disadvantages like higher costs compared to manual machines.

In this experiment, we are learnt how does a CNC machine works and to interpret the G- codes. G-code is the command system for the CNC (Computer Numerical Code) Machine. G- codes are any word in a CNC program that begins with the letter G. Generally it is a code that tells the machine tool to perform specific actions.This document provides details on performing various operations on a CNC machine, including drilling, profiling, and pocketing. It outlines the experimental setup, procedures, sample G-code programs, and results.To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC sequence, cycle time, and manuscript for part P-34, 4) simulate the g-code written for P-34 on the CNC simulators, 5) write the CNC sequence, cycle time, and manuscript for the tension specimen.

To reiterate, the main objectives of this lab were to 1) familiarize students with CNC machinery, 2) understand how to write CNC code, 3) write the CNC sequence, cycle time, and manuscript for part P-34, 4) simulate the g-code written for P-34 on the CNC simulators, 5) write the CNC sequence, cycle time, and manuscript for the tension specimen.After this lab, I can understand the G-code and know what its movement in the CNC machine will be. It is a useful and efficient way for engineers to use CNC machine to make a large number of parts in less time.This document summarizes a CNC lab visit and provides information about programming a given part. It describes the machine specifications, how to set up the machine, and how to enter programs. It also discusses simulating programs before running them on a CNC machine.

cnc report pdf

304 stainless steel enclosure

304 stainless steel thermos thermal lunch box

cnc machine report

$14.99

cnc machine lab report|cnc machine report