cnc machine lifespan So a good quality machine is good for about 9-10 years at 40 hours of machine operation a week? That sounds more than adequate, even if I'm really spry and active as an old coot. We leverage numerous fabrication methods, including plate burning, CNC and conventional machining, automated flange drilling, robotic welding with automatic positioning, and many other state-of-the-art technologies to produce flanges with precise tolerances and fine surface finishes.

0 · life expectancy of used machine

1 · life expectancy of a lathe

2 · how long can a cnc machine last

3 · cnc machine life expectancy

4 · 2000 hour lathe life expectancy

China’s sheet metal fabrication industry, renowned for its integration of advanced technology and state-of-the-art machinery like precision laser cutters and automated bending machines to achieve high accuracy and efficiency.

So a good quality machine is good for about 9-10 years at 40 hours of machine operation a week? That sounds more than adequate, even if I'm really spry and active as an old coot.

The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10 .In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their .Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a .

In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC .

Proper maintenance and regular cleaning are essential to prolong the lifespan of a CNC machine. This includes routine inspections, cleaning of cutting tools, lubricating moving parts, and . Predictive maintenance is a revolutionary concept in the manufacturing industry. Not only has it proven integral to substantially extending the lifespan of CNC machines and critical manufacturing equipment, but it also .The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling .

In this blog post, we will explore various strategies to extend the useful life of CNC machines, helping businesses maximize their efficiency and return on investment. 1. Regular . Training your employees on the basic and proper practices on operating and maintaining the CNC machine – simple tasks such as, choosing the proper lubricant and .

So a good quality machine is good for about 9-10 years at 40 hours of machine operation a week? That sounds more than adequate, even if I'm really spry and active as an old coot.

The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10-15 years, or even longer in some cases.In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their efficiency.Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a CNC machine’s lifespan is impacted by many factors.In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC machines can have a lifespan of 15 to 25 years.

Proper maintenance and regular cleaning are essential to prolong the lifespan of a CNC machine. This includes routine inspections, cleaning of cutting tools, lubricating moving parts, and ensuring proper alignment.

life expectancy of used machine

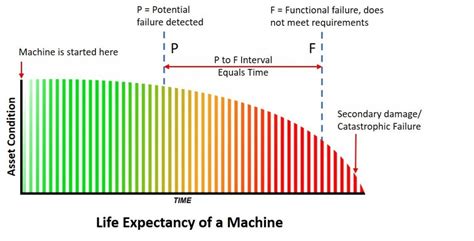

Predictive maintenance is a revolutionary concept in the manufacturing industry. Not only has it proven integral to substantially extending the lifespan of CNC machines and critical manufacturing equipment, but it also promotes productivity, efficiency, and uptime.

The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling machine may be of service for about 10 to 15 years.In this blog post, we will explore various strategies to extend the useful life of CNC machines, helping businesses maximize their efficiency and return on investment. 1. Regular Maintenance and Servicing. Proper maintenance and servicing are key factors in . Training your employees on the basic and proper practices on operating and maintaining the CNC machine – simple tasks such as, choosing the proper lubricant and replacing the fill cap, could impact the machines’ longevity.

So a good quality machine is good for about 9-10 years at 40 hours of machine operation a week? That sounds more than adequate, even if I'm really spry and active as an old coot.

The lifespan of a CNC machine depends on several factors, including the type and quality of the machine, how often it’s used, and how well it’s maintained. On average, a well-maintained CNC machine can last for 10-15 years, or even longer in some cases.In this blog post, we will delve into the factors that influence the life expectancy of CNC machines, discuss maintenance practices to prolong their lifespan, and provide tips for maximizing their efficiency.Generally speaking you can expect a CNC machine to last 15-20 years, but with proper care and maintenance a CNC machine could see a lifespan of over 30 years. As with all machines, a CNC machine’s lifespan is impacted by many factors.In summary, the life expectancy of a CNC machine varies based on factors such as type, usage intensity, and maintenance. Generally, with proper care and regular maintenance, CNC machines can have a lifespan of 15 to 25 years.

Proper maintenance and regular cleaning are essential to prolong the lifespan of a CNC machine. This includes routine inspections, cleaning of cutting tools, lubricating moving parts, and ensuring proper alignment. Predictive maintenance is a revolutionary concept in the manufacturing industry. Not only has it proven integral to substantially extending the lifespan of CNC machines and critical manufacturing equipment, but it also promotes productivity, efficiency, and uptime.The lifespan of a CNC machine depends in large part on the type of machine. For instance, a complex CNC lathe may have a service life of about 20 years, while a basic CNC milling machine may be of service for about 10 to 15 years.

In this blog post, we will explore various strategies to extend the useful life of CNC machines, helping businesses maximize their efficiency and return on investment. 1. Regular Maintenance and Servicing. Proper maintenance and servicing are key factors in .

life expectancy of a lathe

Aluminum extrusion, aluminum forging, CNC aluminum milling, CNC aluminum turning, CNC aluminum drilling, reaming and tapping. Davantech is recognized by its customers around the globe as a thrustworthy supplier and of custom made mechanical components and assemblies.

cnc machine lifespan|life expectancy of a lathe