cnc machine mechanics wrench blueprints Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. We provide professional OEM/ODM precision sheet metal fabrication services, including laser cutting, punching, stamping, CNC bending, machining, welding (laser/TIG/MIG), as well as a wide range of surface treatments and assembly.

0 · cnc parts blueprint pdf

1 · cnc drill hole blueprint

2 · cnc drill blueprint

3 · blueprint reading for cnc

From precision CNC machining to complete fabrication, Pierce Aluminum delivers your project on spec, on time, and on budget. Our one-stop shops can handle any task from simple parts to final assembly of any size project.

wholesale aluminium cnc parts manufacturer

Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included.Start with our guide to blueprints and learn all the basic elements of engineering .

Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time .Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining . This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts .

wholesale aluminum cnc machining service

In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists . Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some . CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and . In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for .

Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included. Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples.

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are .Understand blueprint symbols before production starts: This guide explains different symbols and line types in machining drawings. This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of .

In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists and designers, as they provide a common language for technical drawings and blueprints. Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the .

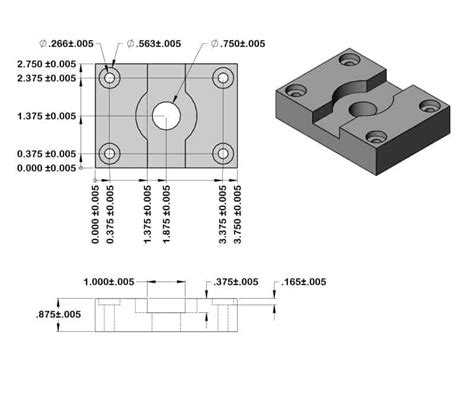

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.

In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for engineers who need to . Check out our full list of machining blueprint symbols to help you figure out what it is and what it does. Pictures of each symbol included. Start with our guide to blueprints and learn all the basic elements of engineering drawings including symbols, terminology and lots of examples. Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.

Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are .Understand blueprint symbols before production starts: This guide explains different symbols and line types in machining drawings. This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of .

In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists and designers, as they provide a common language for technical drawings and blueprints. Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the .

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.

cnc parts blueprint pdf

cnc drill hole blueprint

cnc drill blueprint

DHA America is a leading manufacturer of solar junction boxes designed for medium and large-scale installations. Our products are engineered to withstand harsh environmental conditions while ensuring efficient energy transfer.

cnc machine mechanics wrench blueprints|cnc parts blueprint pdf