bending metal sheet Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Type 4 and 4X Premier disconnects provided with door locking hardware and interlock latches. Modification capabilities to provide special sizes, painted finishes, added holes and cut-outs, pre-installed accessories, and much more.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Shop our modular metal raised garden beds and garden box. 20 Years Design Life. High Quality Paint. Easy to Assemble. No sharp corners. No Soil Contamination.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .

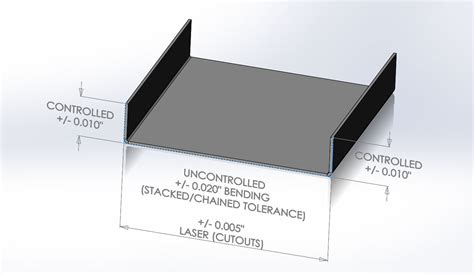

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .

In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results. Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).

distribution code 7 in box 7 on 1099 r

types of bending sheet metal

sheet metal bending standards

Junction Box, IP67 Waterproof Plastic Enclosure for Electrical Project, Hinged Grey Cover, Includes Mounting Plate and Wall Bracket 290×190×140mm (11.4"×7.5"×5.5")

bending metal sheet|sheet metal bending standards