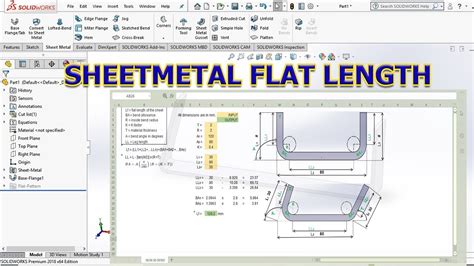

flat pattern sheet metal Sheet Metal flat pattern calculator can be used to calculate sheet metal flat length . CNC machining is a subtractive manufacturing process in which a computer program guides different tools to create a product. The tools include drills, lathes, and mills that cut away at a workpiece to achieve desired specifications.What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .

0 · solidworks sheet metal flat pattern

1 · solidworks no flat pattern configuration

2 · sheet metal flat pattern calculator

3 · sheet metal flat length calculation

4 · sheet metal flat layout calculator

5 · sheet metal calculator layout

6 · flat pattern layout calculator

7 · blank size calculator sheet metal

In electrical terms, an enclosure refers to a cabinet or box that houses electrical or electronic equipment. It’s designed to protect the contents from environmental factors like dust, moisture, and accidental contact, .

Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K .K Factor in sheet metal bending is a constant used to calculate sheet metal .

Sheet Metal flat pattern calculator can be used to calculate sheet metal flat length .Sheet Metal flat pattern calculator can be used to calculate sheet metal flat length as per required sheet metal bend part.

Creating Drawings of Flat Patterns. To create a drawing of a flat pattern: Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, .

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to .K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss .

Add a corner relief feature. It's on the sheet metal tab in the corners menu. Constant radius is probably what you want. Expand the Flat-Pattern folder at the bottom of your feature tree and edit the flat pattern feature. Uncheck the .

The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex . In this tech tip learn how to mirror SOLIDWORKS sheet metal and control whether a flat pattern feature is included With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the industry. On the Idea board, @Anonymous pointed out this brings in the flat pattern in the units that the document is set at: & @Anonymous, You might try: = & rather than: = & I hope this helps.A Flat Pattern is the shape of the sheet metal component before it is formed. Folded sheet metal body Flat pattern view; Flat patterns show bend lines, bend zones, center lines, and the shape of the entire sheet metal body with all bends flattened and bend factors considered.

One of the biggest benefits of Onshape’s Simultaneous Sheet Metal features is the ability to see the flat pattern update in real time as you make changes to your sheet metal part. But what about creating drawings of that flat pattern? Let’s take a look. Inserting flat patterns into drawing views in Onshape is very simple.

wholesale metal mesh fabric

solidworks sheet metal flat pattern

FLAT PATTERN FOR SHEET METAL . CAD hi all, i created this sheet metal part to cut on router. this can be done by DXF file. in design tree is showing two flatten. when un-suppress it will only flatten sheet with bend line and skip the insert so un suppress the second one to create second dxf. which causes the insert shape not in position. is .to transfer the sheet metal information. Form the help: “Transfers the sheet metal and flat pattern information from the original part to the mirrored part such as fixed face, grain direction, bend lines, and bounding box. Some sheet metal features .

If you're planning to create the ribs via brake press, you'll probably also have to thicken this back to the original metal thickness (Knit the surfaces and thicken) and then create a solid-body flat pattern using sheet metal tools If the final drum is going to be rolled in a plate roller, you'll face 2 potential issues: a. Hi, I have a sheet metal part from CATIA that can be flattened in a CATIA sheet metal environment. I am trying to do a similar thing in Inventor but somehow could not figure out this. please assist, is it possible to unfold or make a flat pattern from uneven sheet metal components, if yes then how? I am sharing the component file if you need it!Use the Flat Pattern tool to automatically create a flattened version of a sheet metal part and prepare the model for manufacture. The Flat Pattern feature remains the last feature in the Model Tree and maintains the flat model view. The flat pattern is suppressed when you add or redefine features in a design. It is automatically resumed after .

Multibody part modelling is a very useful design method and can rapidly increase productivity. Often, designer don’t utilise this capability with Sheet metal.

Flat Pattern is nothing but unfolded shape of any sheet metal shapes or fabrication shapes before forming processes such as Bending, Rolling, etc. . In Sheet Metal or Fabrication Industry Flat Pattern making is useful for forming various shapes such as Conical Shapes, Box Shapes, Pipe Shapes, Transition Shapes such as Square to Round or Round .Use sheet metal bend parameters like K-factor, bend allowances, and bend deductions, to ensure accurate flat pattern generation for your sheet metal designs. It's crucial for product manufacturability, ensuring precise dimensions .In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress.; Select Process-Bends and all of the features after it. Click Edit > Suppress > This Configuration to .

Dim oDoc As PartDocument oDoc = ThisDoc.Document 'ensure this part has a flat pattern Dim oSMDef As SheetMetalComponentDefinition oSMDef = oDoc.ComponentDefinition If oSMDef.FlatPattern Is Nothing Then 'tell the .Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material. The layout may either be done on the material .

I know it's an old problem but, did anyone actually find a solution that doesn't involve playing around with code, re-writing bend tolerances or reinventing the K-Factor? I have a simple steel pipe in sheet metal that I have "ripped" to obtain the flat pattern. The correct length should be 314.16 mm when made flat, however, Inventor says it should be nearly 4 mm shorter!

In a sheet metal part, create a new configuration. In the FeatureManager design tree, do one of the following: Right-click Flat-Pattern and select Unsuppress.; Select Process-Bends and all of the features after it. Click Edit > Suppress > This Configuration to . But when I go into my flat pattern that length = 48.878. So I went into my sheet metal defaults and started changing the K factor to get it as close the 48.1988. ( .0075 K-factor). Since we are not sheet metal people, but still make the parts, I try to use and understand the process as time permits.

solidworks no flat pattern configuration

The Flat-Pattern1 feature is intended to be the last feature in the folded sheet metal part. All features before Flat-Pattern1 in the FeatureManager design tree appear in both the folded and flattened sheet metal part. All features after Flat-Pattern1 appear only in the flattened sheet metal part.. Improvements to flattening sheet metal parts make flattening succeed for complex .Convert the Surface-Flatten feature to sheet metal, not merging the body (I'll now have 2 bodies) Add the fillets back in Delete/Keep body as necessary Then just have 2 configurations - a formed one and a flat one - with the appropriate parts of the feature tree suppressed. Formed Features are features that can be seen in the bent/formed state of the geometry, while Flattened Features are features that ONLY show while the flat-pattern is active. Therefore, Solidworks won’t actually propagate any edits on the flat-pattern of your part to the bent state of your sheet metal.

This calculator provides the calculation of flat pattern calculation for sheet metal fabrication. Explanation. Calculation Example: The flat pattern calculation (FPC) is used in sheet metal fabrication to determine the amount of material required to create a specific shape. It is given by the formula FPC = L * W + π * D^2 * N, where L is the . Bend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the bending process. This value is essential for ensuring that the final dimensions of .Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard toolbar), and click OK to open the drawing sheet.; Select a format or click OK to use the default format.; From the View Palette, drag .

wholesale plastic junction box

$25.00

flat pattern sheet metal|solidworks no flat pattern configuration