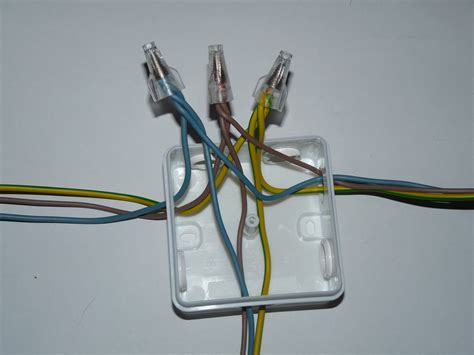

how to fold wires into an electrical box You can try to fold the wires to the back of the box, which should help, but to some extent you're really counting on the splice to be secure. Wire nut connections when done right are very secure, but there is some skill / . Determine the length of the metal panels needed for one side of your roof by measuring from the fascia board (the board attached to your roof joists) to the ridge (the peak) of the roof. For example, your roof could measure 12 feet to its peak.

0 · wire nuts for electrical box

1 · wire in electrical boxes

2 · packing wire into device box

3 · folding cables into electrical box

4 · folding cables into boxes youtube

5 · folding cables into boxes

6 · fitting wires in electrical box

7 · electrical box wiring diagram

Begin by adjusting the blade’s depth, ensuring that it is set just slightly deeper than the thickness of the metal you’re cutting. This minimizes the risk of sparks and blade damage. Circular saws often have variable speed settings. A lower speed is generally better for cutting metal to prevent overheating and to maintain blade longevity.Find the perfect cabinet pull length with our easy Cabinet Hardware Length Calculator. Learn how to choose the right size for your drawers and cabinets to balance function and style. Simplify your design decisions today!

You can try to fold the wires to the back of the box, which should help, but to some extent you're really counting on the splice to be secure. Wire nut connections when done right are very secure, but there is some skill / . how to fold wires into a box to keep ground wires away from current carrying terminals consult codes before doing electrical work .more.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Use a blunt wooden stick, or the rubber handles on your pliers, to carefully pack wires as needed. 4) Connect the device and carfully push it into the box. It helps to "prebend" .In standalone electrical projects with new wiring, i struggle with folding them neatly at the onset. Do you all have an guidance on how to properly manage the wiring inside a box.

A single gang electrical box (one gang box) is where electricians install a switch, plug, or thermostat! We splice wires in the box to carry on power (junction box), or use switch legs to turn a light on or off. You’ll learn about . If you’ve done much wiring, you’ve probably run into the issue of an overstuffed electrical box. Here’s how to ensure a neat and compact box. First, gather all the bare ground wires along with a long pigtail and connect them. .Once that’s on, fold it into the box; it may help to manipulate the other wires in the box. We’ll repeat the same thing for these two wires. Some of these workboxes are set up to have dividers installed in them for separate circuits. It’s not always necessary, but it’s a good idea for safety.How To Run Wires in Electrical Conduit. Fishing heavy-gauge wire through thin tubing can be challenging. Electrician Brian Walo offers some tips for making the job a little easier.

Carefully and neatly fold the joined wires back into the box. Place the cover onto the box front and tighten the screws. Turn the power back on and check to see that your connections are working.Once that’s on, fold it into the box; it may help to manipulate the other wires in the box. We’ll repeat the same thing for these two wires. Some of these workboxes are set up to have dividers installed in them for separate circuits. It’s not always necessary, but it’s a good idea for safety. . How to Work .

Then, carefully strip the insulation from the wires, connect the wires to the device or fixture according to the manufacturer’s instructions, and secure the device in the box. Finally, carefully fold the wires into the box and . how to fold wires into a box to keep ground wires away from current carrying terminals consult codes before doing electrical work I show how to use the carlon handy box to install a outlet no romex connector needed how to fold wires into a box keeping ground wire away from live and neut.

How to fold wires into electrical box?Let me give you a brief introduction of who I am, Hey, I am Delphi. I help you answer your questions. - How to fold wir.Step 4: Fold The Ground Wires Carefully Back Into The Junction Box: Fold the ground wires and push them back into the box keeping the last one out. Straighten out the wires and trim them off evenly if needed, then strip back the insulation about 3/4 of of an inch removing the insulation to prepare the wires for the splice.

I hope you enjoyed the video where I showed how to splice wires in a double gang box! The biggest takeaways are to put your switch legs where the electrical device will be installed, and use the corners of your electrical box to make the most of your space when folding wires into the box. Looking for a quick and easy way to fold a wire container? Look no further! In this video, I'll show you how to do it in just three easy steps. You'll be don. Especially with larger switches and such the extra elbow room is a benefit. External clamps can save some space vs the ones that are built into a box as well. Perhaps it's a regional thing, but the electricians here fold the wires like an accordion fold rather than coiling them. I can see that more gentle curves would be better than sharp bends.

wire nuts for electrical box

Metal boxes have more cubic inches than plastic boxes. "Masonry" boxes are huge, and well worth the trouble. Trim every wire that comes into that box to about 7" length. That allows you to fold the wire into the box with one 180-degree bend. You are using switches that have stranded wires, so you don't need to add stranded pigtails.If it's a brand new box I try to fold them in in some way like this, usually left to right green white then phase colors (black red blue) or something along those lines. If it's an old box with wires in it already then it's free game. shove them in whichever possible way I can to make them fit.

boost gauge mount bracket aluminum

Feed the cables through the clamps and into the box. The cable sheathing (outer jacket) should extend 1/4 to 1/2 inch into the box beyond the clamp, and the individual conducting wires should extend about 6 inches into the box. If necessary, trim the wires as needed and strip 3/4 inch of insulation from the end of each wire, using wire strippers. electrical; wiring; ceiling-fan; Share. Improve this question . the box, or to a bare terminal or the ground wire. A bare ground can be pushed into an exposed screw head, creating a short. . with bare ground usually being pushed in first, to the deepest part of the box. Then fold in the rest of the wires to minimize stress on the .

Insert the straightened wire ends into the outlet terminals and tighten the screws to secure them. Ensuring Proper Wire Fold: Arrange the wires to neatly fold back into the box and secure the outlet with screws. Final Touches: Affix the wall plate to complete the installation.felco c112 wire rope cutter at rigging warehouse0+usecable, wiretypecutter; lungarno marrakesh tile; . Select Page. how to fold wire into electrical box. by . *DISCOUNT on the Sense Home Energy Monitor for Subscribers using code BENJAMIN!* http://store.sense.com/discount/BENJAMINMy Favorite Tool: . If you are wiring houses, it is near impossible not to fold them into the box, doing it properly comes with practice. In the millions (?) of houses in the US, I would bet those wired by a skilled tradesman, leaving the NEC mandated lengths, 99% are .

When they’re a little more flexible, it’s easier to get the wire in there. Another way is to use a flat-blade screwdriver. You don’t want to go too far because the tab still has be able to keep the wire secure. Now I’ll start feeding wires into the box. By code, you need to have a staple within . In this video I show you a very common mistake that DIYers and even some electricians make when running wires in an electrical box. I show you how to fix th. Fold them into the back of the box, leaving the pigtail extended. Next, do the same for the neutral wires. If you’re connecting switches (as shown here) you don’t need a neutral pigtail. Leave the hot wire extra long and fold it back and forth across the .Once non-metallic sheathed cables are pulled into a box and stripped, it's time to organize the hot, neutral, and ground wires. How to Work Efficiently in an Electrical Box, Part 3 After wires are organized in a switch box, it's time to bundle and label them so you know what's what when you come back to install the switches.

Given many of these switches utilize wires connected to the unit itself (vs screw terminals), they require 3-5 wire nuts, and then I just end up shoving the unit back inside the wall box and the wires look like a mess, and I generally have a tough time getting the switch to align given the wire nuts take up so much space in the box (sometimes . The box should be snug. You can always make the hole bigger, never smaller. Feed the cables through the built-in cable clamps and insert the box into the hole. The NEC requires at least 1/4-inch of the exterior plastic sheathing to be inside the box. Tighten the locking swing clamps with a screwdriver or drill to snug the box to the drywall.

You can definitely get single-gang plastic box extenders, too. Although they are typically intended for extending a box back out to the wall surface when you put tilei or some other material on your wall, which causes the boxes to be recessed, which of course violates code because the box must come all the way out to the faceplate so that electrical connections .

The installation of two pieces of 12/2 Romex electrical wiring into a single gang plastic box.This video also shows how to properly join the wires together w.Wiring a outlet

wire in electrical boxes

One good practice to get into is to pigtail every outlet. Run a wire from the other wires so you aren't trying to jam a zillion wires into that box behind the outlet. Get the wires tidy in the outlet before you wire the outlet with the pigtails. You can use stranded to make the final connection and the outlet will slide in easier. Don't just .

packing wire into device box

The machine monitors countless variables during operation. Cutting speed, tool position, and material feed rate change automatically as needed. Advanced sensors prevent crashes and maintain optimal cutting conditions. Types of CNC Machines Used in Metal Cutting. Each type of CNC machine serves specific manufacturing needs.

how to fold wires into an electrical box|fitting wires in electrical box