cnc machine reference point stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.

0 · unity cnc reference point

1 · setting a reference point in cnc

2 · reference point in cnc

3 · cnc offsets formula

4 · cnc offsets

5 · cnc offset machine reference

6 · cnc offset function

7 · cnc machine reference

Using our advanced review methodology, we’ve evaluated the top metal and steel fabrication software based on value for money, integration options, and supported manufacturing environments. STRUMIS: Best for Structural Metal Fabricators; ProShop ERP: Best for Machine Shops; Fulcrum Pro: Best for Sheet Metal Fabrication

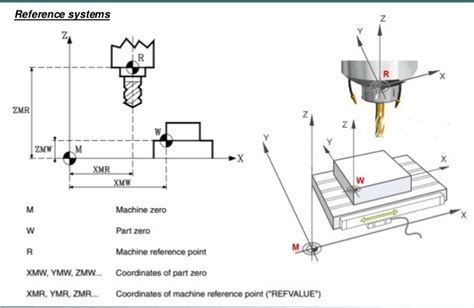

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and .

The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the .

The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine . stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal . The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the .

Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual .Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and . The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining . Machine reference point. Every CNC machine has its own origin point or Home location that will serve as the machine’s coordinate system’s origin. The machine reference .

unity cnc reference point

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and consistency in the machining process.The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the complete machine measuring system .The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine comes to know its current axis position.

setting a reference point in cnc

A machines reference position or home position, as it is sometimes referred to, is the point at which all 3 axes read Zero. This is usually set as far as the machine can move in a positive direction in all 3 axes. stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal uses software limits and position the table in mid travel as the zero position.other than the Z axis.

The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the machine tool manufacturer in each feed axis, and the coordinate value of the fixed position point has been recorded in the . Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual position does not normally change.

The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning.Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools. The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining operations. It is typically set at the extreme end of each .

A reference point in CNC is a fixed location on the machine bed that serves as the starting point for all machining operations. It is used to establish the machine’s coordinate system and ensure accuracy and consistency in the machining process.The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point , the machine reference point is a fixed point as base for the complete machine measuring system .The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine comes to know its current axis position.

A machines reference position or home position, as it is sometimes referred to, is the point at which all 3 axes read Zero. This is usually set as far as the machine can move in a positive direction in all 3 axes. stored in each motor's encoder of the zero return position. Unlike some of the other machine configurations where you have limit switches to set the machine home, Fadal uses software limits and position the table in mid travel as the zero position.other than the Z axis. The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the machine tool manufacturer in each feed axis, and the coordinate value of the fixed position point has been recorded in the .

how many wires in a 4x4 junction box

Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual position does not normally change.

The absolute type of servo motor enables the reset the reference point without using the zero-return decelerating signal (Dog type). There are two ways to achieve accurate positioning.Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and movement of the cutting tools.

reference point in cnc

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

cnc machine reference point|cnc offset machine reference