sheet metal deep drawn parts quotes This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad . $24.29

0 · sheet metal drawing techniques

1 · sheet metal drawing process

2 · sheet metal drawing definition

3 · how to draw sheet metal

4 · deep metal drawing

5 · deep drawing of sheet metal

6 · deep drawing metal parts

7 · deep drawing die

$48.99

Get Fast Sheet Metal Quotes with Design Feedback Before ordering sheet metal parts, you might question if your design is ready for manufacturing and optimized for aesthetics and long-term .The deep drawing process follows a series of carefully controlled steps: Blanking: We cut the stainless steel sheet to size. Lubrication: We apply a specialized lubricant to reduce friction. .

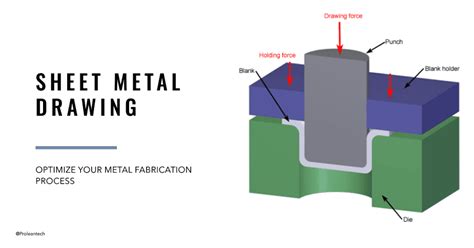

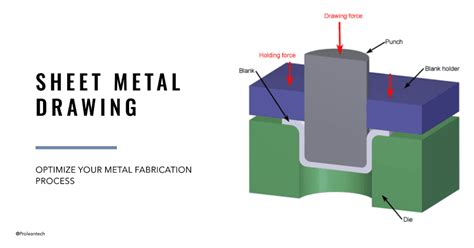

This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. We’ll delve into its foundational principles, the technical aspects, and myriad . A highly specialized metal drawing process, deep drawing utilizes a punch and ring to transform a sheet metal blank into a shaped component through tensile and compressive force. . :2015-certified quality management system (QMS) ensures that we achieve all established quality objectives, delivering parts like deep drawn cans and containers .

We present superior quality deep drawn parts that are manufactured from best quality steel to guarantee our authenticity to customers. Ensuring high durability and efficacious performance the sheet metal deep drawn parts offered by us . Deep-draw metal stamping is a process where flat metal sheets are drawn into dies to form hollow shapes. Think of it like pushing the dough into a mould but with metal—and much more force! It’s efficient, cost-effective, and ideal for high-volume production of intricate parts like cans, enclosures, and automotive components.

Wier(Beijing) New Material Co.,Ltd: Wier - Professional sheet metal fabrication factory in china. Custom any sheet metal parts and stamping parts for your project. Professional one-stop factory for OEM &ODM metal fittings. . WIER offers the most cost-effective prototyping solutions with instant quotes and fast delivery. . Deep Drawn Metal . Stainless Steel Type 201/201L: This is an austenitic, non-magnetic, low-nickel stainless steel. It is generally used in draw forming sheet metal and deep draw stamping.Its lower nickel content makes it a more cost-effective alternative to Type 304. Stainless Steel Type 304/304L: This is the most commonly used stainless steel. It is an austenitic grade that can be .

We are teh leading Manufacturer and Supplier of an exclusive range of Deep Drawn Shell, Deep Draw Steel Component, Sheet Metal Parts, Deep Draw Components, Sheet Metal Components and Deep Drawing Dies etc. Read More.

Single-Action Hydraulic Deep Drawing Presses Applications of Sheet Metal Machinery 3.1 Definition and Basic Functionality. Single-action hydraulic deep drawing presses are the simplest type of hydraulic press used for deep drawing operations. In a single-action press, a single hydraulic cylinder is used to generate the force needed to move the . Deep drawing is one of the most commonly used metal forming techniques. It is used by numerous sectors, including the automotive, medical, manufacturing, and aerospace industries, to create various parts and complex shapes from metal sheets. The deep drawing process begins by placing a flat piece of sheet metal on a forming die.They judiciously utilize all the resources and manufacture our range of Sheet Metal & Welded Parts and Relay, . Deep Sheet Metal Components Private Limited A-2/9, Makarpura, G.I.D.C Vadodara-390010, Vadodara-390010, . and we’ll help you get quotes. Tell us what you need. Receive seller details. Seal the . [email protected]. 815 ZhongYang Building, No.24 Fuhai Road Fuyong Community, Bao’an District.Shenzhen, 518103 . Table 2: Step-by-step procedure of sheet metal deep-drawing. Step Description; Blank Placement: A flat, round sheet of metal, referred to as a blank, is placed over the die cavity. . Additionally, since drawn parts are .

Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. . Deep drawing excels at creating deep, cylindrical parts from flat sheet metal. It’s ideal for producing cups, cans, and other hollow forms. The process allows for .

cnc drawing machine circuit diagram

sheet metal drawing techniques

The material is then squeezed between the male and female die parts. The portion is cooled after the initial push. Hot drawing can create two pieces per hour, making it perfect for tiny, specific orders made of materials that cannot be cold formed. Grade 5 6Al-4V titanium, for example, cannot be cold-formed. . Deep drawing is a sheet metal . In contrast, the objective of a deep-drawing operation is to flow sheetmetal into a die cavity to produce the required shape with minimal material stretching and thinning. Deep Drawing Explained: The Basics. Deep drawing produces a part from a flat blank via the action of a punch force onto the blank.

Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. . produced at high speeds, and often at lower costs than competing methods. Deep drawn parts are found in . Deep drawing changes flat sheet metal into complex shapes without any seams. It uses a punch and die to shape the metal into the desired form. This process can make parts with cylindrical or conical shapes. . By focusing on these design elements, makers can create top-notch deep-drawn parts. These parts are needed in many fields, from cars to . The sheet metal drawing process, a key aspect of metalworking, is an art of transformation that has been perfected over centuries. It breathes life into mundane metal sheets, sculpting them into a myriad of shapes and forms .

Deep drawing is a metal forming process used to produce complex, high-quality components from sheet metals. It is widely employed in industries to create parts like automotive components, kitchen sinks, and beverage cans. The deep draw process is crucial for producing components by transforming flat metal sheets into hollow, cylindrical, or box-shaped parts through the use of a .

Get Price Quote. Size : L 1000mm, W 600mm, D 200mm Deep Drawn Sheet Metal Parts, that we offer, are made with MS sheet and have upto 180 mm depth. Electrical and other industries require Deep Drawn Sheet Metal Parts and metal forming components. 300 tons double action hydraulic machine is used to manufacture Deep Drawn Metal Comp more. We produce quality CNC machined parts, sheet metal fabricating, Deep Drawing,metal stamping prototypes and production, fiber laser cutting, tool and die making and related services. We also have our own Stamping Die development, design and production plant.Drawing parts are workpieces obtained by stretching and deforming sheets by mechanical equipment. Now we will introduce the production standards of drawing parts. 1. The first-wall surface, bottom surface and wall surface of the deep-drawing part, and the corner radius of the four corners of the .

Buy Deep Drawn Parts from Tribeca coppers pvt ltd Find Company contact details & address in Mumbai, MH | ID: 152688Our stamping capacity reaches 1300mm(51’’)X1000mm(40”),material thick-ness 20mm(0.78’’),deep drawn depth 450mm(17.7”), diameter 1000mm(39.4”). As a professional OEM Stamping, Deep Drawing, And Welding For Metal Parts And Components Manufacturer and Metal Prts Factory, We have our own mold development, design, and production plant .

Metal Deep Drawing. Metal Deep Drawing: The deep drawing process is a critical metal forming technique used across various industries, from automotive to aerospace, for producing high-quality, precision metal parts.A central element in the success of the deep drawing process is the hydraulic press, a versatile and highly controlled machine that allows .

Deep drawing of parabolic parts; Deep drawing is more difficult than spherical parts. Common drawing methods are: (1) Shallow paraboloid (h/d <0.5 ~ 0.6). Because its height-to-diameter ratio is nearly spherical, the drawing method is the same as that of spherical parts. (2) Deep paraboloid (h/d> 0.5 ~ 0.6). Its deepening difficulty has . The study presented in this paper addresses the inspection of deep drawn parts using rectangular cups as an example. For this purpose, a corresponding deep drawing tool was mounted in the servo mechanical press (Aida NST-S2-6300(D)-305-150-SERVO) of the Institute for Metal Forming Technology in Stuttgart and 30 cup parts were manufactured.

sheet metal drawing process

In the deep drawing process, a flat sheet metal blank is placed over a die cavity, and a punch is used to press the blank into the die. . Titanium’s high strength allows it to be formed into thin-walled, deep-drawn parts that can withstand extreme conditions without adding unnecessary weight. 6.3 Applications in Aerospace and Medical Devices.Deep drawing retains the thickness of the sheet metal material and produces highly accurate, repeatable components. Deep drawing is a cost-effective process for manufacturing applications requiring high precision and high volumes of parts. Deep drawing also works well for products of lightweight material that require a significant amount of .

cnc embrodering machine

Wall-Mount Mailbox with Flag Metal Mail Box for Outside Large Capacity Rust-Proof Post Box for House Use, 14.2” x 4” x 9.5”, Black

sheet metal deep drawn parts quotes|deep drawing metal parts