how to make a hole in a junction box Once you’ve determined the optimal location, follow these steps to drill the hole for your junction box: 1. Mark the drilling location: Using a pencil, mark the center point of the . Wooden boxes are known for their durability and classic look, while foam boxes offer a softer landing surface (meaning less potential for injury). Metal boxes are often lightweight, easily.

0 · step drill for junction box

1 · drilling hole in junction box

2 · drilling a junction box

3 · drill bit for junction box

$13.99

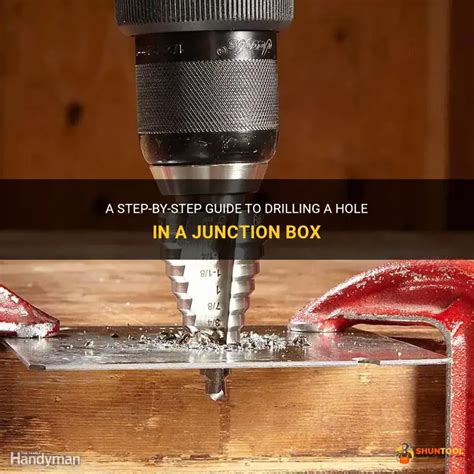

If you're looking to drill a hole in a junction box, it's important to have the right equipment and tools on hand to ensure a clean and precise hole. Whether you're a beginner or experienced DIYer, this guide will walk you through the necessary materials needed for this task.

By drilling a hole in the junction box, you create a designated entry point for the . IBEW member Jennifer Smith leads this weeks job tip by showing us how to drill into a junction box or panel without breaking your drill bit. First, you will need a cordless drill, a half. How to drill hole on a junction box using a step drill? 0:00 / 1:01. 3keego Step Drills are drill bits EASY to DRILL and ENLARGE a wide range of holes on thin sheet metal. [Check Our. Once you’ve determined the optimal location, follow these steps to drill the hole for your junction box: 1. Mark the drilling location: Using a pencil, mark the center point of the .

In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil.

step drill for junction box

drilling hole in junction box

By drilling a hole in the junction box, you create a designated entry point for the wires to enter and exit the box. This ensures that the wires are tightly secured and cannot be . Drilling the Hole. Put on your safety glasses and gloves. Insert the drill bit into the drill. Position the drill on the marked spot and start drilling slowly. Apply gentle pressure and . Mount the junction box to the wall by screwing in screws through the designated holes. Use wire strippers to strip 3⁄4 inch (19 mm) of casing insulation off the end of every wire going into the junction box. Twist the . Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on .

Drilling the Hole for Your Junction Box. Once you’ve determined the optimal location, follow these steps to drill the hole for your junction box: 1. Mark the drilling location: Using a pencil, mark the center point of the junction box on the wall. 2. Pilot hole: Drill a small pilot hole using a drill bit slightly smaller than the diameter of the junction box mounting holes. Electrical - AC & DC - can you drill your own holes in plastic boxes? - The person im working with would like to drill out a hole for the entry of bx cable in a plastic box. . but I have never needed to do the same for a junction box. Upvote #5 10-29-03, 04:25 PM T. Tim T. Member. Thread Starter. Join Date: Sep 2003. Location: USA. Posts: 165 .Just through the side and not the top. There’s no code for clamping wires as they enter a junction box. Which makes sense because you don’t do that when you pull wires through EMT. I have this plastic residential single gang box. I haven’t found a code violation about drilling a hole in the side of a junction box either.

I removed a Romex cable that was going into a junction box top middle opening(you can see in the picture). There is still an opening at that punch out. . (depending on supplier - some are over a buck, I'd keep shopping), snaps into the hole (take the clamp out first.) Share. Improve this answer. Follow answered Mar 27, 2017 at 1:18. Ecnerwal .110.3 says it needs to be listed for the application, and much the same as other junction boxes, there's not much in the way of excluding making your own holes 314 says in order to use it as a junction box that contains splices the body has to be stamped with the amount of cubic area, but that doesn't exclude making holes in the side and adding .

drilling a junction box

If not you probably can rent one. They typically come in sets. You will need to drill a hole maybe 3/8" depending on the punch set. You then place the bolt through the die, then place the bolt through the hole you drilled, then thread the punch on the end of the bolt. Tighten with an appropriate wrench and it will give you the hole you need.Pull the box out of the wall and look inside to see what’s causing it to be crooked. Shave the stud, trim the drywall, shim, ect to fix the problem. You can reuse the old box or use a new one that has the angled holes for securing to the stud with screws. Set the new box so it’s not protruding. Put everything back together.

Re: 4X4X4 holeless PVC Junction Boxes I did recently learn that drilling new mounting holes in these boxes (less than 100 square inches volume) is a UL violation. You have to use the mounting "tabs" moulded on or supplied with the box. I'm thinking (guessing actually) that drilling the covers might not be a UL acceptable use. I assume you used this box to avoid tearing up a bunch of drywall. So let’s try for a solution that avoids that. Mount a piece of wood inside the wall along the edge of the opening and mount to this piece of wood.A cross strap is a common way to adapt the larger size down to the smaller size. Screws to 3 1/2 box and 2 3/4 fixture mounts to strap bracket. Some 2 3/4" boxes, particularly the metal styles, can allow a strap bracket to be mounted to the box and let the ends overhang the box so that screws on 3 1/2" centers can clear the outside of the box. Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new hole, and re-mount the outlet. Replace the box. If it were me, I would do number 3. Obviously, make sure the electricity to the outlet is turned off before doing any work. Edit 1 : OP says the box .

steel kittens boxing 221porn free

Replacing light fixture - plastic junction box has broken screw holes? I am working on renovating my kitchen, and am in the process of replacing a light fixture. When I went to install the mounting bracket for my new fixture, I found that the holes in the junction box were broken . I can't remember because I removed the old fixture a couple .In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil. Position the junction box over the hole and secure it using screws or bolts. Make sure the box is flush with the wall or ceiling. Connecting the Wires. Strip the ends of the wires about 1/2 inch. Twist the bare ends of the wires together and insert them into the appropriate terminals in the junction box. #cement #pouringconcrete #concreteIn this video I show you how to pour a concrete junction box with a manhole.

Fill the gap using a special trick.so we've got an electrical box where thwhere there's nothing for it at thebottom to grip so I made this two layerpiece of . That's as easy as a junction box inside with a short conduit nipple to outside and some THWN wires. . then feed it through a small hole in the wall into the back of a box. The box could be an old-work box recessed into the siding or a surface-mounted weatherproof box. Finishing touches after drilling a hole in a junction box. After drilling a hole in a junction box, there are a few important finishing touches that need to be done to ensure a safe and secure electrical connection. These steps will help to prevent any issues and maintain the integrity of the junction box.

After slicing 90 deg the box would be rotated 90 deg to continue the cut . . . Alternatively, the box could be held down on a flat surface and the knife held with the cutting edge away from the thumb. The removal would be with a slicing action from above then the box flipped over for slicing the remainder.Patch the old hole with a self-sticking drywall patch, then mount a new box to the joist about 8" further away from the wall. There are boxes that can be screwed right into the joist from below the ceiling (look for Madison Electric Products Fan and Fixture 1-Gang Gray Polycarbonate New Work/Old Work Standard Ceiling Fan Ceiling Electrical Box).

It not uncommon for boxes to be only 1.5 inches deep. So you can pull your 1.5 inch box and install, say, a 3.5 inch one. As far as extensions, there are things called box extensions, but they serve a different purpose. For example, if you add tile to a wall with an existing outlet, you can use a box extension to fill the gap created by the tile. There is a round hole there right now (from a recessed light that I removed). The problem is this round hole is just short in diameter of standard junctions boxes (octagonal ones). A rectangular junction box will fit through the hole however. The question is: are there any code regulations that I cannot have a rectangular junction box in a . IBEW member Jennifer Smith leads this weeks job tip by showing us how to drill into a junction box or panel without breaking your drill bit. First, you will .Just thought I'd share my solution for this problem more specificly with a mud ring. If you take a zip in or 1/4" bit tip screw and pre drill into the lip of the mud ring you can then take the screws they give you hrough the factory holes and just fasten to the side of the ring the backplate will cover the rest of the box hole

Find the Hood Line - If you find another junction box that feeds the hood, you may be able to disconnect the cable that is dedicated to the hood at that earlier junction box. BE SURE THAT ALL WIRES IN THE JUNCTION BOX ARE DE-ENERGIZED! You can use a non-contact tester to confirm before handling any of them. 2014 NEC allows weep holes in the box as long as the hole is ¼ in. or smaller. There is no limit on the number of holes or location where they are drilled but the holes must be “approved”. According to Article 100, “approved” means acceptable to .Septic System Distribution Box Review and Setup Tuf-Tite Distribution Box Setup y Review Tuf-Tite 4 Hole Distribution Box with fitting (For 4 inch Pipe)Discr.

drill bit for junction box

Take your woodworking skills to the next level with a standing CNC system or benchtop CNC machine from Woodcraft! We carry everything from portable laser engravers and carving systems to handheld CNC routers from today’s top manufacturers, like xTool, Next Wave SHARK, & .

how to make a hole in a junction box|drilling a junction box