mig welding automotive sheet metal dvd In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I demonstrated this.

In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend compresses while the outer portion expands (see Figure 1).

0 · welding 24 gauge sheet metal

1 · welder settings for sheet metal

2 · tig welding sheet metal videos

3 · tig welding automotive sheet metal

4 · mig welding thin metal settings

5 · mig welding sheet metal basics

6 · mig welding sheet metal 101

7 · mig welding body panel videos

What is a CNC Spindle? A CNC spindle refers to the shaft on a machine tool that drives the workpiece or the cutting tool to rotate. Except for machine tools like planers and broaching machines, which have linear main movements, most CNC machine tools are equipped with spindle components.

Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how very easy it is to start MIG. Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

Mig Welding Automotive Sheetmetal This clip from howtoASAP.com is from a 52 minute instructional DVD shot in HD featuring nationally recognized automotive builder, Craig Hopkins.Free Shipping - Auto Metal Direct Auto Body MIG Welding DVDs with qualifying orders of 9. Shop Digital How To and Reference Media at Summit Racing.Ron Covell goes through the entire process step-by-step, and gives clear descriptions of how each factor changes the weld, including wire speed, .

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I demonstrated this.Motorcycle Metal Fabrication: from Sheet to Street, by Ron Fournier, 2 DVD set. Discusses building of all sheet metal parts from scratch. Features building of tank, fenders, fairing, seat .

Besides this, you will get an idea of TIG welding, metal prep or rust repair, automotive troubleshooting, and paint techniques. The DVDs will also help you understand the process of .

All the information that you can find on this Forum about MIG welding thin sheet metal refers to the need for low current settings, typically 20 to 30 Amps. . @eddie49 yes I also read that 20-30A were needed for thin . I welded up some sheet metal with my new to me MM250 with the standard .035 wire. The tack, tack, tack method worked great for me and can be fast once you get into it. This was my second actual MIG weld I done going from the sheet metal to 1/4" box tube. Patch panel repairs are one of the most common welding tasks you might encounter when restoring old vehicles. The question often comes up about which method is better for the task – MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas).The short answer is that MIG welding and TIG welding are both completely acceptable ways to make clean, reliable sheet .

Lap welding auto body sheet metal with a MIG welder is made easy in the short video. Concentrates on tips that can help make your welding more robotic, neat.

MIG Welding. MIG (Metal Inert Gas) welding is another popular choice for automotive fabrication. It uses a consumable wire electrode and an inert gas to create a strong and clean weld. MIG welding offers versatility and is suitable for a wide range of automotive sheet metal applications. TIG Welding You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal. The Miller Electric 211 dual-voltage welder is the best portable machine for MIG welding automotive work available online. It’s slightly more expensive than the other machines we reviewed, but its capacity to perform far exceeds the price difference. It’s one of the most reliable welders on the market, and yet is low-priced and portable compared to other elite MIG welders . It’s easier for me to tack in place with the Mig, then gas weld. I have a 3-1 machine that has Tig, I’m just not good enough to use it on light gauge metal. With a O/A I can come “in and out” and control things. My 3-1 doesn’t have a foot pedal so I .

An introduction and overview of the basics of MIG welding and of the elements of safety in welding. Some of the discussion has a focus, admittedly on the Miller welders, but is easily generalized to welders from other sources. My son and I moved on from this video to our first welding practice sessions, and then on to a comprehensive text book.

Enter the world of Flux Core Welding (FCW), a versatile technique with a unique approach to fusing materials.This method revolutionizes how welders approach sheet metal, from automotive repairs to constructing metal artworks.Grasping the principles of Flux Core Welding is essential for anyone interested in mastering this skill to achieve strong, durable, and reliable . MIG welding machines are the most popular piece of equipment for repairing car parts, specifically car panels. However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels.Go to Welding r/Welding. r/Welding . Inverter vs Transformer MIG for automotive sheet metal . Need Help Hey guys, Been doing some rust repair on my old BJ70 Toyota Land Cruiser with a MIG I borrowed from a colleague. It's an extremely nice Kemppi 180 amp inverter welder - modern thing where you set the material and thickness in very fine .

Anyone who has worked with welding automotive sheet metal in any capacity knows that it can be a part of challenge. There’s a reason why mechanics, carpenters. . MiG Welding. Welding Automotive Sheet Metal- Tips &Tricks for .

Demonstrating the basics of mig welding sheet metal to Zach who is a first time beginner 🔥@lincolnelectrictv IF YOU ENJOYED WATCHING:subscribe, leave a comm.

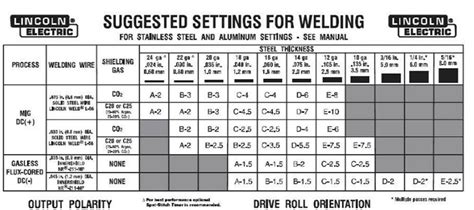

Browse suggested weld parameter settings for Stick Welding, TIG Welding, MIG (Solid-Wire) Welding and MIG (Flux-Core) Welding. They show .030 for 22 gauge.I have been using .035 on my panels.but it's a bit of work trying not to burn through..but I have been doing it directing the heat towards the new steel and letting it flow over. Welding is an essential skill in automotive restoration. CHPVIDEOS.COM's -- Auto Body MIG Welding / CHP#5 welding video puts you inside of the welding helme. ER70S-6 is a general-purpose alloy used for welding mild steel. It's often used for butt and fillet welding of sheet and plate, and is suitable for welding steels with moderate amounts of rust or scale. probably more info than needed.

Auto Metal Direct offers these instructional videos in a DVD format to guide you through automotive body projects. They show installation and repair techniques off / off 9 / off 9 / 0 off 9* - Use Promo Code: SALE Hi just wondering what the best practice / best tools would be to take down a weld on automotive sheet metal to get a seemless finish. I have been using a 5 inch angle grinder with a 120g flap disc but I don’t feel 100% consistent and am paranoid about taking it down to far or unevenly. 5 inch is potentially too wide and taking metal off the surrounding areas unnecessarily? In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

Welding. Automotive sheet metal fabrication uses heat to join two or more materials. Common welding techniques include spot welding, MIG welding, and TIG welding. Sheet metal welding is suitable for joining similar materials. It is highly compatible with many materials, creating strong and durable auto parts. The Hobart Handler 140 MIG Welder is my top choice because of its versatility and user friendly interface. It is capable of welding thin sheet metals because of its low minimum amperage range and has a smooth and stable arc. It is ideal for hobby welders that can complete their sheet metal welding job without requiring a high duty cycle. weldingsupply.com is the best price that I have ever found on the Esab Easy-grind wire,in both .023 and .030 sizes and the silicon bronze wire,also.I actually buy all of my wire and most of my supplies from them.Thier shipping cost is quite low also.Here is a link.You will have to scroll down the page quite a ways.I have introduced several boby shops in my area to this wire .

welding 24 gauge sheet metal

MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two popular welding methods, each with distinct advantages: . TIG welding is preferred in high-tech, high-impact industries like automotive and aerospace due to its ability to produce strong, quality welds on thin materials. The operator’s manual control over the filler .

MIG Yes. MIG welding stands for "Metal- Inert Gas." By definition MIG requires a bottle of inert shielding gas, often 25% CO2 and 75% Argon. This is ideal for things like auto body tnin sheet metal. Although a seperate shield gas is often used industrially for flux core welding. Some wire types don't need an external shield. All MetalShaping > General Metal Shaping Discussion > General Discussion: ron covell dvd - mig welding MIG welders are best recommended for these applications as MIG welding is the most common procedure used by people who make and work with sheet metal. Is it possible to stick weld sheet metal? Yes, you can stick weld sheet metal less than ⅛’’ thick, but you will need the right machine and a good set of welding skills to get the job done.

michael miller glitz metallic chic chevron pearlized mist fabric

metroplex sheet metal

A manufacturing process known as precision sheet metal fabrication entails shaping unfinished metal sheets into components that will be combined into completed products. The metal sheet can be "subtracted," which means smaller shapes are cut from it, or molded into a special shape.Precision machining is a complex manufacturing process that utilizes specialized machinery and tooling to create parts with extremely tight tolerances and complex designs.

mig welding automotive sheet metal dvd|tig welding automotive sheet metal