electrical box cutout size Sizes: The standard, single-switch size is 2 inches by 4 inches, with depths ranging from 1 1/2 inches to 3 1/2 inches. Four-inch boxes are used as junction boxes or for . This metal bank comes in three sizes ranging from 4.72 to 7.9 inches. The square box is very durable and has a slot suitable for both bills and coins. It's for just a one-time use because opening it requires breaking the box.

0 · plastic cut in boxes electrical

1 · oscillating tool electrical box cutter

2 · oscillating electrical box cutter

3 · multi tool outlet box cutter

4 · multi tool electrical box cutter

5 · electrical cut in box size

6 · electrical box drywall cutter

7 · cutting electrical boxes in drywall

1.3%-1.4% carbon: Used where a keen cutting edge is necessary (razors, saws, .

Sizes: The standard, single-switch size is 2 inches by 4 inches, with depths ranging from 1 1/2 inches to 3 1/2 inches. Four-inch boxes are used as junction boxes or for .Electrical boxes come in a seemingly endless variety of sizes and styles, .Designed specifically for cutting out single and double gang metal old work boxes, this wall template level is perfect for ensuring the boxes are level every time. This wall template level . Cut the box out while not getting over a 1/8 in or so from the outer sides of the ceiling box. Make the cuts to where the DW board will eventually slide up and over the box, .

Making accurate electrical box cutouts boils down to a simple method that allows you to slice through drywall while leaving the box, and the wires within, undamaged. Take your time cutting a lath-and-plaster wall when installing an electrical box. It's easy to damage the surrounding area. Most plaster is attached to ⅜-inch-thick wood lath, which cuts fairly easily if it does not vibrate. If it .

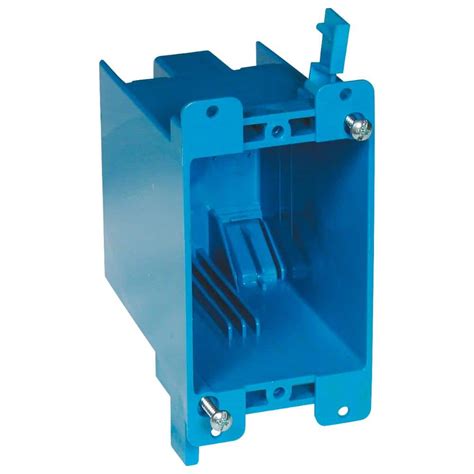

Designed specifically for cutting out single and double gang non-metallic old work boxes, this wall template level is perfect for ensuring the boxes are level every time.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes. Standard rectangular boxes, or single gang boxes, are used for single light fixture switches and outlet receptacles. They are generally about 2 inches wide by 4 inches tall, and their depths range from 1-1/2 inches to 3-1/2 .There are a number of cut-in boxes to choose from. The most common have side-mounted ears that swing out or expand as you turn their screws. Hold the box against the drywall, plumb it 1, then trace the outline of the box onto the wall 2.

Sizes: The standard, single-switch size is 2 inches by 4 inches, with depths ranging from 1 1/2 inches to 3 1/2 inches. Four-inch boxes are used as junction boxes or for multiple conductors and connectors running in different directions.

plastic cut in boxes electrical

Designed specifically for cutting out single and double gang metal old work boxes, this wall template level is perfect for ensuring the boxes are level every time. This wall template level features the following: Cut the box out while not getting over a 1/8 in or so from the outer sides of the ceiling box. Make the cuts to where the DW board will eventually slide up and over the box, and then it will bottom out against the ceiling joists (or existing structure). Now finish fastening the board permanently. . All done. And don't be discouraged too fast. Making accurate electrical box cutouts boils down to a simple method that allows you to slice through drywall while leaving the box, and the wires within, undamaged. Electrical boxes come in a seemingly endless variety of sizes and styles, including metallic (steel) versions, which requires grounding of the box. On the other hand, you can opt for nonmetallic versions (PVC, phenolic resin, or fiberglass), which do not require grounding of .

Take your time cutting a lath-and-plaster wall when installing an electrical box. It's easy to damage the surrounding area. Most plaster is attached to ⅜-inch-thick wood lath, which cuts fairly easily if it does not vibrate. If it does vibrate as .

Designed specifically for cutting out single and double gang non-metallic old work boxes, this wall template level is perfect for ensuring the boxes are level every time.

There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes.

oscillating tool electrical box cutter

oscillating electrical box cutter

multi tool outlet box cutter

Standard rectangular boxes, or single gang boxes, are used for single light fixture switches and outlet receptacles. They are generally about 2 inches wide by 4 inches tall, and their depths range from 1-1/2 inches to 3-1/2 inches. Standard rectangular boxes can .There are a number of cut-in boxes to choose from. The most common have side-mounted ears that swing out or expand as you turn their screws. Hold the box against the drywall, plumb it 1, then trace the outline of the box onto the wall 2.

Sizes: The standard, single-switch size is 2 inches by 4 inches, with depths ranging from 1 1/2 inches to 3 1/2 inches. Four-inch boxes are used as junction boxes or for multiple conductors and connectors running in different directions.

Designed specifically for cutting out single and double gang metal old work boxes, this wall template level is perfect for ensuring the boxes are level every time. This wall template level features the following:

Cut the box out while not getting over a 1/8 in or so from the outer sides of the ceiling box. Make the cuts to where the DW board will eventually slide up and over the box, and then it will bottom out against the ceiling joists (or existing structure). Now finish fastening the board permanently. . All done. And don't be discouraged too fast. Making accurate electrical box cutouts boils down to a simple method that allows you to slice through drywall while leaving the box, and the wires within, undamaged. Electrical boxes come in a seemingly endless variety of sizes and styles, including metallic (steel) versions, which requires grounding of the box. On the other hand, you can opt for nonmetallic versions (PVC, phenolic resin, or fiberglass), which do not require grounding of .

Take your time cutting a lath-and-plaster wall when installing an electrical box. It's easy to damage the surrounding area. Most plaster is attached to ⅜-inch-thick wood lath, which cuts fairly easily if it does not vibrate. If it does vibrate as .Designed specifically for cutting out single and double gang non-metallic old work boxes, this wall template level is perfect for ensuring the boxes are level every time.There is a huge selection of electrical boxes, varying by size, shape, mounting device, and composition. One of the first distinctions to note is that of new work boxes and remodel or cut-in boxes.

Standard rectangular boxes, or single gang boxes, are used for single light fixture switches and outlet receptacles. They are generally about 2 inches wide by 4 inches tall, and their depths range from 1-1/2 inches to 3-1/2 inches. Standard rectangular boxes can .

metal plaster bracket suppliers

metal pickup tool box

CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to control the movement and operation of machine tools. CNC machining applications: CNC machines can be used to create various parts and products from different materials, such as metals, plastics, wood, and composites.

electrical box cutout size|multi tool electrical box cutter