cnc machine guide Want to become a CNC machining master? Look no further! We've got everything you need to know about programming, blueprint reading and more.

Our precision manufacturing services are competitively priced, and we produce custom parts to your exact standards. We pride ourselves on our efficiency. From quotes to delivery, you can trust our team to deliver custom CNC parts on time.

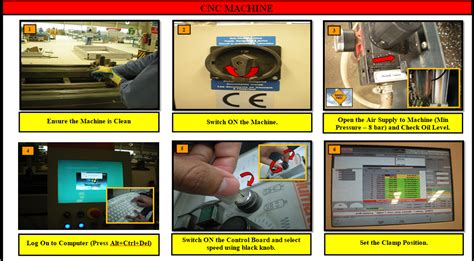

0 · work instruction for cnc machine

1 · manual machinist vs cnc

2 · haas cnc lathe manual pdf

3 · cnc vs manual machining

4 · cnc machine operation manual pdf

5 · cnc machine operating instructions

6 · cnc machine manual pdf

7 · cnc machine a beginner's guide

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, .

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages . CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write .In this beginner's guide, we will explore the world of CNC machines and how to operate them effectively. Whether new to CNC machining or looking to enhance your skills, this guide will provide valuable insights and step-by-step .

steel bento box canada

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the .Want to become a CNC machining master? Look no further! We've got everything you need to know about programming, blueprint reading and more.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your .

A Guide to CNC Machines. Learn how CNC machines can speed up your making process and turn 2D or 3D designs into a wide range of parts and products.

To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring.In this beginner's guide, we will explore the world of CNC machines and how to operate them effectively. Whether new to CNC machining or looking to enhance your skills, this guide will provide valuable insights and step-by-step instructions. There are numerous advantages to using a CNC machine.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .

Want to become a CNC machining master? Look no further! We've got everything you need to know about programming, blueprint reading and more.

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field. CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools.A Guide to CNC Machines. Learn how CNC machines can speed up your making process and turn 2D or 3D designs into a wide range of parts and products. To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the . CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring.

In this beginner's guide, we will explore the world of CNC machines and how to operate them effectively. Whether new to CNC machining or looking to enhance your skills, this guide will provide valuable insights and step-by-step instructions. There are numerous advantages to using a CNC machine.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .Want to become a CNC machining master? Look no further! We've got everything you need to know about programming, blueprint reading and more.

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field. CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools.

steel box 18 wide x 28 long x 24 height

work instruction for cnc machine

steel box bar sizes

manual machinist vs cnc

haas cnc lathe manual pdf

Improve your application with titanium parts or assemblies from Moon Tool & Die Co. We are an ISO 9001:2015-certified CNC machine shop specializing in the manufacture of precision components and construction of multifaceted upper-level products for challenging projects.

cnc machine guide|work instruction for cnc machine