coining process in sheet metal Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for .

Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches.

0 · types of sheet metal dies

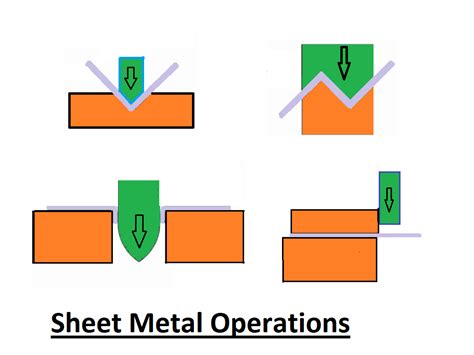

1 · sheet metal operations with diagrams

2 · restrike process in sheet metal

3 · embossing operation in sheet metal

4 · drawing process in sheet metal

5 · drawing operation in sheet metal

6 · coining process in metal stamping

7 · bending drawing sheet metal

eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.

Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.The coining pressure can be applied to the sheet metal at BDC by using the stationary function. This type of motion, called “dwell motion,” has three segments: rising, long dwell, and descent. .

Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are .Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it .

Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for . Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several .This article focuses on the coining equipment (hammers and presses), lubricants, and general and special die materials used in the coining process. It discusses the coinability of metals such as steels, copper, and composite metals.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation.

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.The coining pressure can be applied to the sheet metal at BDC by using the stationary function. This type of motion, called “dwell motion,” has three segments: rising, long dwell, and descent. For a metal forming process, the long dwell time results in uniform metal deformation.

Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are incompressible.

Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products. Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.This article focuses on the coining equipment (hammers and presses), lubricants, and general and special die materials used in the coining process. It discusses the coinability of metals such as steels, copper, and composite metals.

Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

20mm junction box

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.The coining pressure can be applied to the sheet metal at BDC by using the stationary function. This type of motion, called “dwell motion,” has three segments: rising, long dwell, and descent. For a metal forming process, the long dwell time results in uniform metal deformation.Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are incompressible.Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press.

Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products. Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.

types of sheet metal dies

Cnc Metal Parts Manufacturers, Factory, Suppliers From China, We believe that a passionate, innovative and well-trained team will be able to establish good and mutually beneficial business relationships with you soon.

coining process in sheet metal|restrike process in sheet metal