applications of cnc machines in manufacturing industry CNC machining finds applications across various industries, including: Aerospace: Manufacturing complex components with stringent quality and safety standards. Automotive: Producing . Study with Quizlet and memorize flashcards containing terms like In a properly wired 120 V electric circuit, the hot wire is generally • Black or red • Bare • Green • White or gray, Water puts out a fire by • Creating a chain reaction • Cutting off the oxygen supply • Reducing the fuel temperature • Scattering the fuel, OSHA's .

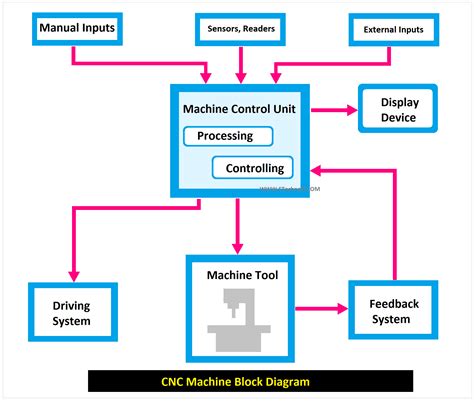

0 · schematic diagram of cnc machine

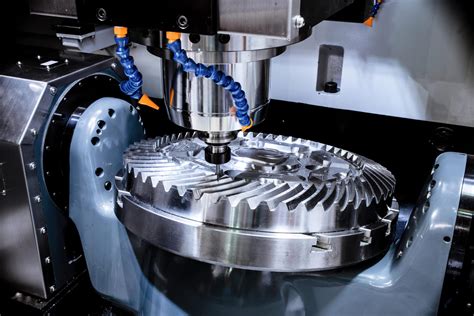

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

A clear demonstration of how to correctly turn right at a yellow box junction. This was filmed on a Crewe driving test route, but the same rules apply to al.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines , exploring . CNC machines have transformed manufacturing by offering unmatched precision and efficiency across various practices. With automation and accuracy being more critical than .CNC machining finds applications across various industries, including: Aerospace: Manufacturing complex components with stringent quality and safety standards. Automotive: Producing .

CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing .CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used .

Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to .

CNC machines enable the production of critical components with high accuracy and consistency for industries ranging from aerospace to oil and gas. As the technology continues .CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. . CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines , exploring their evolution, applications, benefits, challenges, and . CNC machines have transformed manufacturing by offering unmatched precision and efficiency across various practices. With automation and accuracy being more critical than ever, CNC machines are crucial equipment even in aerospace and jewelry making, demonstrating their versatile scope of work.CNC machining finds applications across various industries, including: Aerospace: Manufacturing complex components with stringent quality and safety standards. Automotive: Producing precision parts that require high levels of accuracy and repeatability. Medical: Fabricating implants and surgical instruments with biocompatible materials.CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens .

CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used to create prototypes, molds, and final products in various plastic materials with complex geometries.

Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities? CNC machines enable the production of critical components with high accuracy and consistency for industries ranging from aerospace to oil and gas. As the technology continues to evolve, CNC's role in shaping the future of manufacturing will only become more significant.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machines have revolutionized the manufacturing industry, bringing unparalleled precision and efficiency to various sectors. In this comprehensive guide, we’ll dive into the world of CNC machines , exploring their evolution, applications, benefits, challenges, and . CNC machines have transformed manufacturing by offering unmatched precision and efficiency across various practices. With automation and accuracy being more critical than ever, CNC machines are crucial equipment even in aerospace and jewelry making, demonstrating their versatile scope of work.CNC machining finds applications across various industries, including: Aerospace: Manufacturing complex components with stringent quality and safety standards. Automotive: Producing precision parts that require high levels of accuracy and repeatability. Medical: Fabricating implants and surgical instruments with biocompatible materials.

CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens .CNC machines play a critical role in the plastic fabrication industry, providing increased flexibility and precision in the manufacturing of a wide range of products. These machines can be used to create prototypes, molds, and final products in various plastic materials with complex geometries.

Computer numerical control (CNC) machining has been a staple process in manufacturing. CNC technology combines computer programming and mechanical machining to produce various products, from everyday items to complex parts. Let's explore its CNC machining capabilities and applications in multiple industries. What Are CNC Capabilities?

CNC machines enable the production of critical components with high accuracy and consistency for industries ranging from aerospace to oil and gas. As the technology continues to evolve, CNC's role in shaping the future of manufacturing will only become more significant.

electrical box g40401200mb

schematic diagram of cnc machine

products made by milling machine

$45.90

applications of cnc machines in manufacturing industry|products made by milling machine