tig welding sheet metal edge Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these . Generally used in a heat-treated state, Tool Steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. 860.289.1529 Get a quote

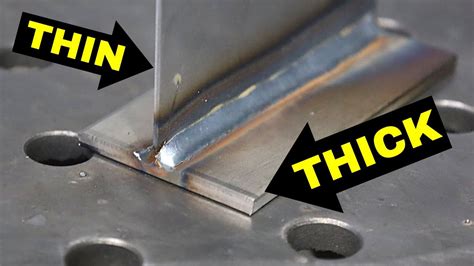

0 · welding thin to thick metal

1 · welding stainless steel sheet metal

2 · welding sheet metal without warping

3 · welding 14 gauge sheet metal

4 · tig welding stainless sheet metal

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

$86.98

Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .

For this weekly video, lets do some edge welding and talk about gas shielding, amperage, and how chill blocks can help with gas shielding and discoloration. On stainless steel sheet metal, sometimes its ok to fuse without filler on an edge .TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise .

In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for .

In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. tig welding sheet metal 08-21-2007, 08:21 PM. hi everyone new to the forums and new to tig. . Start the arc a bit from the edge and move in, watching everything carefully. You might practice by getting some sheet metal and drilling the same sized holes in it, and go from there. Good luck, James Comment . That year, the operation made an unusual first move into sheet metal fabrication automation, with the purchase of a TIG welding robot. The company needed to seam-weld thin sheet metal to produce a weather-proof, . Exclusive, Patent Pending, Design Provides A Perfectly Beveled 45° Weld-Prepped Edge In 20 Or 18 Gauge Sheet Metal ; Proper Weld-Prepped Edges Allow Strong, Flush, Crack-Free Welds In Sheet Metal ; Each Strike Forms A Perfect 0.062” X 45° Beveled Flange ; Achieve Solid, Full-Penetration Mig Or Tig Butt Welds

5 MIG vs TIG Welding for Custom Cut Sheet Metal. 6 DFM Guidelines For Sheet Metal Design. 6.1 7 Key Factors in Sheet Metal Design. . Hemming: The hemming process forms a two-layered section by bending the edge of a sheet metal piece to the other side of the piece. This process typically occurs in two stages: shaping the metal to a V-die and .Mastering TIG Welding Techniques for Sheet Metal. TIG welding sheet metal demands precision and skill. Let’s explore the techniques that will elevate your welding game. Key Principles of TIG Welding Sheet Metal. Success in TIG welding sheet metal hinges on several core principles: Maintain a short arc length, typically 1/8 inch or less.

personally, I'd make the bottom sheet an inch or two larger in every dimension, trim the corners, then bend the excess to 90 degrees. this changes the weld from a corner weld into a lap weld, which is much easier to do on sheet metal.

welding thin to thick metal

welding stainless steel sheet metal

electric box 2 level 29 solution

11. Sheet Metal Tips. As mentioned in the introduction, sheet metal work is a different animal than steel beams. Any of the above practices can be useful in mitigating distortion in sheet metal, but there are additional practices that can come into play and perhaps save the day. These include: Water-Cooled Jig MIG welding sheet metal requires a combination of technical expertise, precision, and dedication to continuous improvement. By understanding the nuances of sheet metal welding, considering critical factors, and honing your welding techniques, you can achieve exceptional weld quality and elevate the overall standard of your welded assemblies. Gun is pointed UP @ 5 deg. and as stated it is fast, and make sure you are on the leading edge of the weld puddle. Get in a position so you can weld to the bottom in one motion practice without pulling the trigger. Mig vertical down can cold lap if your not on the edge. Weld can look good but will lap over the base metal and not penetrate.

Edge Weld Sheet Metal Thread starter imagineers; Start date Jan 6, 2015; Status Not open for further replies. Jan 6, 2015 #1 imagineers Mechanical. Nov 2, 2010 162 CA. . then Tig weld from the outside using filler rod to fill that gap. Galvaneal Tig welds quite nicely. Sand smooth after welding, or leave alone depending on the skill of the .Sheet Metal Fabrication . An on-going commitment to invest in the latest cutting-edge machinery and techniques, supported by experienced project management and customer service, enables the company to deliver fit for purpose products and components including one-off fabrications and batch production. . Welding: TIG, MIG & ARC . ASM works with .At Academy Sheetmetal, we bring together a skilled team and top-notch equipment to meet all your welding needs. From MIG and TIG welding to utilising advanced robotics, we handle a wide range of applications with precision and care. With our committed team, your welding requirements are in expert hands, ensuring each join is strong and precise.

Salem Metal, Inc. is a full-service family run shop specializing in panels, brackets, enclosures, and sub-assemblies. Our modern facility is equipped to handle everything from precision sheet-metal fabrication, sophisticated CNC machining to spray painting. Our highly experienced team is ready to respond to your questions or needs. Your Vision. The term TIG is short for Tungsten _____ welding. Inert gas. 1 / 59. 1 / 59. Flashcards; Learn; Test; . The term _____ refers to a fusion weld made without the addition of filler metal. Autogenous weld . and reinforcement while having minimum penetration. Surfacing welds _____ is the proco of holding the file across the edge of the blade at .

I am creating a water tight sheet metal box, and would like to specify on the drawing where and how to weld the edges closed. . Edge weld on sheet metal box 3. Thread starter imagineers; Start date Nov 24, 2014; Status . If you insist on torch welding this part (TIG) heliarc is recommended. Then I would suggest you up the gauge to 18 gauge .

6061 Aluminum Plate: Comes with 12pcs aluminum sheets, size - 2”x 4”x 1/8”(0.118") / 50 x 100 x 3 mm ; Durable Aluminum Sheet: The aluminum sheet metal made of 6061 aluminum alloy with high hardness, corrosion . Tacking thin/sheet metal. New to the forum and trying to tack thin (.040-.060) sheet metal. . Open to suggestions. I have tried backing up the piece off the table but still blow through the edge. Top. tweake. tweake; Weldmonger; Posts: 1720. Joined: Mon Dec 18, 2017 9:53 am. Location: . ↳ Metal Cutting; ↳ Tig Welding - Tig Welding .Precision Steel Fabrication & Welding Shop in Tulsa OK specializes in custom metal work of all types, including HVAC & sheet metal products.

Common types of joints you'll find when working with sheet metal are the butt joint, edge joint, and the flush corner joint. . The difficulty in welding sheet metal is that you need to get good penetration to make a nice weld and fuse the pieces together, but the problem is that you can easily burn right through the material because it heats . The Backstep technique for tig welding is a way to limit distortion on thin sheet metal. Backstepping is when the direction of travel is in one direction. i have a miller syncrowave 200 and tried to tig up some thin .035" thick sheet metal. was trying to butt weld, but it kept burning the edges away before fusion took place. . A good exercise would be to weld the edge of .035 you should be able to add rod and increase the size of the metal with the application of rod (gap filling exercise) you . 5 likes, 1 comments - texasedgebbq on October 10, 2024: "Stainless steel TIG welding, cosmetic sheet metal".

Controlling the Heat Input And Welding On Thin Sheet Metals. Pulse TIG is the most efficient way of controlling the heat input and the heat-affected zone, especially for sensitive stainless steel or other thin sheet metal plates. . Creating corner or edge welds is challenging, especially if joining thin sheet metal. As you start welding, the .

Highlighting our sheet metal processing capabilities are our CNC laser cutters. CNC Forming . Our state-of-the art tube laser is on the cutting edge (literally)! . Our in-house capabilities include both MIG and TIG welding, catering to carbon steel, . TIG Welding Sheet Metal. Tungsten Inert Gas (TIG) welding, or Gas Tungsten Arc Welding (GTAW), requires more manual dexterity, offering high levels of precision and control. . Ensure snug fit-up for butt, lap, T, corner, and edge joints. An accurate fit-up contributes to both the aesthetic and structural integrity of the weld. Following these .

We employ cutting-edge equipment and techniques, ensuring your sheet metal components are produced with precision and efficiency. . Get started on your sheet metal project today by contacting our expert team at NTP, and let us help you save money, space, and time while delivering exceptional results. . TIG Welding TIG (Tungsten Inert Gas . TIG welding allows the welder more control. Learn from Ron Covell about the different tungsten electrodes available for a variety of welding applications. . even for light-gauge sheet metal, and I can weld metals ¼-inch thick, or more. The most common length for tungsten electrodes is 7 inches. For working in restricted areas, it may be .

electric box 2 level 22 solution

welding sheet metal without warping

This first aid cabinet is a heavy-gauge steel cabinet that features four fixed shelves. Each cabinet includes a pull-out shelf extension at the bottom which provides a handy work area for .

tig welding sheet metal edge|welding thin to thick metal