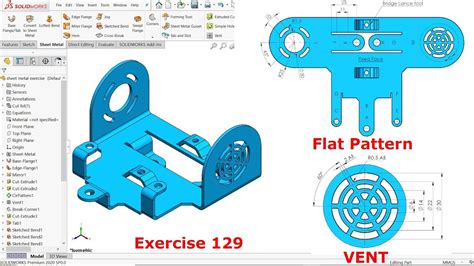

sheet metal part drawing example Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . Exploring Bombay Sapphire cocktails reveals the secret behind their popularity: the gin’s unique botanical blend. This special touch transforms simple drinks into something extraordinary, from floral gin and tonics to zesty citrus mixes and sophisticated spiced creations.

0 · solidworks sheet metal drawings

1 · simple sheet metal drawings

2 · sheet metal layout drawings

3 · sheet metal drawings with gd&t

4 · sheet metal command in solidworks

5 · sheet metal basic drawing

6 · sheet metal 3d sketch solidworks

7 · metal sheet riveted together drawing

Choosing the right type of electrical box is critical for the safety and performance of your electrical system. From standard rectangular boxes to weatherproof options, there’s a .

what can you use for a metal bracket

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to .

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the . Reading an engineering drawing is crucial to be able to properly convey the design intent of a sheet metal part. Without this ability, designers and (most) fabricators won’t be able to work together to produce acceptable parts, and you could wind up with a pile of useless laser cut parts that don’t work. . Above is an example of a part . This is a small project of making a part of sheet metal of 2 mm thickness. The project includes making related 3D CAD files and drawings in DWG and PDF format. . Sheet Metal - Part 001 - Drawing.pdf. pdf. June 15th, 2021 Sheet Metal - Part 001 - Drawing.dwg. dwg. . Can you send to me example of this part uses. 11 Jan 2023 1:51 AM Md .Can you guys please critique my sheet metal drawing? How can I improve to drawing to make the part easier to manufacture? Advertisement Coins. 0 coins. Premium Powerups . If you aren't including a solid model you need to fully .

wet rated junction box

I typically use one drawing per individual sheet metal part, and if it is welded that is treated as one weldment part. The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating .I do cad at a sheet metal fab shop. Don’t bother with a flat view, we decide what the flat will look like to get your desired part. In the first one, I’d say you’re pretty close to what I would like to see, except you dimensioned to the center of the bend radius, which is bad for a couple reasons: you didn’t tell me what the radius is drawn at, and you don’t know what bend radius I .Where to Find Sheet Metal Template Information. Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the .Template (Fig. SM.2). Sheet metal parts can also be used in assemblies, along with other Pro/E and/or Pro/SHEETMETAL parts. In addition, sheet metal parts can . Sheet metal drawings usually contain views both of the fully formed part and of the flat pattern, as in Figure SM.4. You

Does anyone have any examples or know of any resource that have examples of manufacturing drawings for complex parts? By complex, I mean parts such as transmission covers, engine blocks, automotive doors/panels, complex cast and pressed parts, etc. Most of the drawings online are parts that contain simple shapes, features, and holes. Overview of Sheet Metal Drawing Key Concepts in Sheet Metal Drawing. Sheet Metal Drawing: A manufacturing process that involves shaping metal sheets into desired forms using a punch and die system.; Applications: Commonly used for producing items like scuba tanks, soda cans, and flashlights, which require precise shapes and dimensions.; Deep .

Tips to calculate bend deduction in CAD software: Create sheet metal part: Start by creating or importing your 3D sheet metal model in SolidWorks. Define material and thickness: Ensure that you have defined the correct material and thickness for your sheet metal part. This information is crucial for calculating the bend deduction accurately. Sheet Metal drawing process. Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without thinning or altering the sheet’s thickness. This subtle yet complex operation is pivotal for industries aiming to produce accurate and consistent hollow shapes.When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents. Explore essential quality metrics for sheet metal fabrication drawings. Ensure precision and efficiency with expert insights from HitechDigital. . The workflow often includes a quality check where a sample of parts is measured and recorded. Data from these measurements are then compared against the tolerance requirements detailed in the drawings.

5. REQUIREMENTS FOR SHEET METAL PART DRAWINGS Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. See document 10-0005, Blah Drawing & Drafting Standards and Practices , for the proper setup of a sheet metal drawing. Processing sheet metal materials from ultra-high-strength steels represents a promising and economically viable approach to produce sophisticated, light-weight car body structures [].Yet deep drawing of such dedicated high-strength steels poses a challenging task for manufacturers due to their limited formability, the high process loads during forming and the .

Where to Find Sheet Metal Template Information. Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the .

Here is a tutorial to walk you through defining the 3D PMI on a sheet metal part. Similarly, a sheet metal assembly tutorial is also available. They are part of an online series of 12 free learning modules including videos, click .The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Compared with the surface of the electro-galvanized sheet, the coating is thicker and is mainly used for sheet metal parts that require high corrosion resistance. 4) Aluminum-zinc plate The aluminum-zinc alloy coating of the aluminum-zinc plate is composed of 55% aluminum, 43.4% zinc and 1.6% silicon at 600 ° C. In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. . Examples of drawing are pans, tubes, and cams. Read also: Drilling Machine: Parts, Types, Operations with PDF 7. Embossing

geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude,For your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing reviews, so you can catch any last minute mistakes before your parts are released. All of your sheet metal DFM work will be wasted if you can’t communicate the requirements of your parts to . Punching of a sheet metal part Bending (Forming) Sheet metal pieces are usually cut, punched and then bent (order may vary depending on the features). Bending involves a punch, a die and the work part. The sheet meal work part is sandwiched between the die and the punch. The punch is brought down sharply using a hydraulic ram, to bend the sheet .

SOLIDWORKS Sheet Metal Properties can be added to Drawings using a predefined annotation or selectively using standard annotation property mapping syntax. . ___Difference Between Drawing Template and Sheet Format ___Apply Sheet Format to New Sheets; . How to create SOLIDWORKS Part, Assembly, and Drawing Templates; Found this on a post from 2007: 1 - Open your sheet metal template, click on the parameters button, and check the option to export the Thickness parameter as a custom iproperty 2 (optional) - Check the iproperties of your sheet metal part file and verify the Thickness was added to the Custom tab. 3 - Open your drawing template, go to iproperties dialog, custom tab .

Drawings of Sheet Metal Parts: Creating Sheet Metal Flat Pattern Configurations: Sheet Metal Gauge/Bend Table: Sheet Metal Gauge Tables: Document Properties - Sheet Metal . For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part.' 1) Sheet metal part is open. ' 2) Adjust paper template size, height, and width. ' ' Postconditions: ' Anew A1 sized drawing is generated with ' a flattened view of the sheet metal part ' with no bend lines showing. ' '-----Option Explicit . Public Enum swDwgPaperSizes_e

solidworks sheet metal drawings

simple sheet metal drawings

sheet metal layout drawings

The size of screws you need for an electrical box will depend on the type of box and the thickness of the wall. For most standard electrical boxes, you will need 6 screws. If .

sheet metal part drawing example|simple sheet metal drawings