how to mig weld 11 gauge sheet metal Typical welding parameters for MIG welding using 0.025 inches (0.6 mm) and 0.030 inches (0.8 mm) wire are given in the below table. When welding 20 gauge sheet, use welding current around 30-35 ampere with a gas .

Looking for high-quality wholesale CNC turning parts? Huayi International Industry Group Limited offers a wide selection of precision machined components for your business needs.

0 · what is mig welding

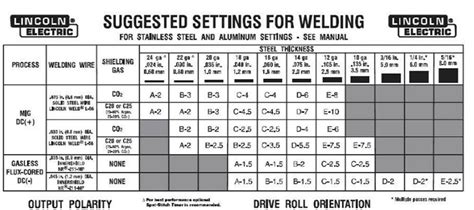

1 · mig welding sheet metal chart

2 · mig welding settings

3 · mig welder for sheet metal

4 · mig sheet metal welding instructions

5 · how to mig weld sheet metal

6 · how thick are mig welding

7 · gauge welding sheet metal

Bring your boldest ideas to life with CNC routers that deliver precision, durability, and ease of use. Whether you’re a hobbyist or a professional, our machines are built to help you turn .

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. How To MIG Weld Thin Gauge Material. Paul is back to sharing tips on how to MIG weld thin gauge material (thin carbon steel). Download the WELD™ APP, join the welding. Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .

what is mig welding

mig welding sheet metal chart

I keep blowing through my thin sheet! Andy gives helpful insights and tips to MIG weld thin sheet metal.KINGMETALS.com. Typical welding parameters for MIG welding using 0.025 inches (0.6 mm) and 0.030 inches (0.8 mm) wire are given in the below table. When welding 20 gauge sheet, use welding current around 30-35 ampere with a gas .We will explain how MIG deals with sheet metal, medium or "hobbyist" steel, and thick plates and what you will need to weld them successfully. By the end of the article, you should understand where MIG welding shines and where it comes .

The problem with welding sheet metal or thin gauge steel is that you can easily blow holes in the panel and create a big mess quickly. We decided to give you some tips when .

To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. . 11 posts For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal. General Welding Questions; Choice of mig wire size for 16 gauge metal; . I am about to start a new project using 16 gauge sheet metal and all I have for wire at the moment is .030. . but only .023 is available from them in 8" 11 lb spools. Go figure.-Mondo Member, AWS Lincoln ProMIG 140 Lincoln AC Tombstone Craftsman Lathe 12 x 24 c1935 .

pvc electrical gang box

mig welding settings

pvc junction box catalogue

Anybody have any advice on tig welding 18 gauge steel? I can seem to do 16 gauge alright way down at 9 amps but 18 gauge is just blow through from the moment I pull the trigger. . Hobart MIG Lincoln Idealarc 250. Reply . 05-16-2014 #7. MikeGyver. View Profile View Forum Posts . The joint will not lay in position long enough to tack. It's up . Welding sheet metal is a completely different ballgame. When you're trying to fuse two pieces of 22 gauge (.030) things can easily go south!In this episode w. I keep blowing through my thin sheet! Andy gives helpful insights and tips to MIG weld thin sheet metal.KINGMETALS.com In this video I show how to Mig weld any gap. This process is useful when you get your cuts off a little bit or your angles are off a little. This happens to.

An introduction to MIG welding sheet metal, covering the basics and advantages. MIG welding stands for Metal Inert Gas welding. It is a type of welding that uses a continuous wire feed. This makes it easier to weld thin sheet metal. MIG welding is popular for its simplicity and speed. It is also known as Gas Metal Arc Welding (GMAW). .

Photo by welding_mani MIG Welding Sheet Metal. Gas metal arc welding (GMAW or MIG) can be successfully used to weld thin metal, but as long as you take extra care. . The heat input is the main issue with sheet metal of 24 gauge up to 14 ga. Thin metal is not so forgiving, so even the slightest heat over the recommended can cause distortion . In this video I show how to set up your mig welder to be able to weld on super thin metal with out warping it. I go through step by step comparing how to pre.|Starting from scratch and setting up two different mig welders to weld sheet metal

Hi, i will take a pic of that but don't think the machine have amp/volts.. I can do good weld but the problem sheeting metal.. Too thin and could find 20 gauge sheet metal around my areas.. Here another photo of the weld and does anyone here know how to fill those gap..Learn how to MIG weld sheet metal effectively. Our expert guidance helps you achieve professional, durable welds with ease. (647) 563-2382 . Though it is possible to weld these joints on 16 gauge, weld appearance will be poor. It would be much more favourable to use TIG instead, and you will likely save yourself time from having to repair . As a rule, when MIG welding sheet metal, never use a body filler metal that is thicker than the base metal. It is recommended that a welder should use .023- or .024-inch wire for light gauge sheet metal work. However, if you are dealing with materials that are 18-gauge or thicker, one should be able to use .030-inch welding wire.

mig welder for sheet metal

In March, we asked a trivia question about the best welding process for joining 18 gauge sheet metal to 2" bar stock. In this video, our technical advisor, C.

We're learning to MIG weld thin 22 gauge sheet metal with the Eastwood MP140i multi process welder. . We're learning to MIG weld thin 22 gauge sheet metal with the Eastwood MP140i multi process .

The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc .

There are several techniques you can try to MIG weld thin metal sheets. What size MIG wire is best for sheet metal? As a rule of thumb, you can remember not to use filler wire that is thicker than the base metal. For MIG welding thin gauge metal sheets, most commonly 0.023-inch or 0.024-inch wire is used. Can you MIG weld sheet metal without . You'll never warp another panel again after watching this video. This is a realtime, step by step demonstration that shows how to mig weld sheet metal withou. Demonstrating the basics of mig welding sheet metal to Zach who is a first time beginner 🔥@lincolnelectrictv IF YOU ENJOYED WATCHING:subscribe, leave a comm.

in this video I weld together 20 gauge sheet metal and then try to break the weld by folding it in half. I use an everlast 160sth welder and 1/16" er70s-2 fi. In this video I show you how to prepare, make and Tig weld in your own patch panel. The Tig process is my favorite process of welding. This panel is being in.

Addressing Challenges and Tips:Flux core welding, especially on delicate 22-gauge sheet metal, isn't a walk in the park. Burn-through, we're looking at you! But fear not, the guide's got your back. Anti-spatter spray, a clean workspace, and swift issue addressing – consider them your flux core survival kit. Finishing Touches. Hold your horses!

putting metal siding on a house

Welding Process. You will need to choose a welding process that allows you to control the heat. The best processes for this are MIG and TIG. It is possible to stick weld on thin sheet metal, but it’s harder to control the heat, it’s messy and it’s hard to master.Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

In this video I show you how to set up your MIG welder and also prepare your metal for the plug welding process. I try to walk you through the entire process.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

CNC custom machined watch case is specifically designed and manufactured watch cases using Computer Numerical Control (CNC) machines.

how to mig weld 11 gauge sheet metal|gauge welding sheet metal