costing of sheet metal parts Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.

Zero Skateboards is a skateboard company located in Carlsbad, California, United States. The brand was founded by professional skateboarder and entrepreneur Jamie Thomas, and distributed by his Black Box Distribution company.

0 · sheet metal production cost calculator

1 · sheet metal parts cost estimator

2 · sheet metal manufacturing costs

3 · sheet metal manufacturing cost estimator

4 · sheet metal fabrication cost

5 · sheet metal cutting cost

6 · sheet metal cost calculator

7 · how much does sheet metal cost

These sheet metal screws look like regular flat head screws, such as stainless steel hex head cap screws. However, they usually have more girdles. This plays the role of making the screws have a more finished appearance when in place. As with the other types of screws, you can also order them with Phillips or slotted heads.

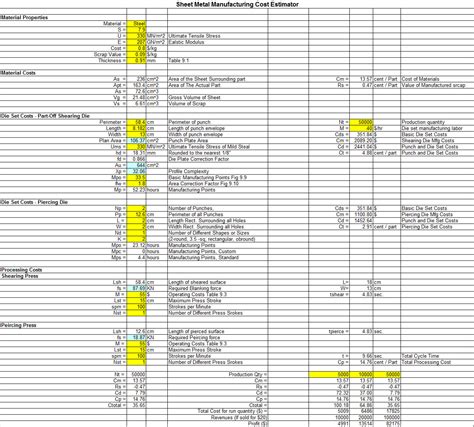

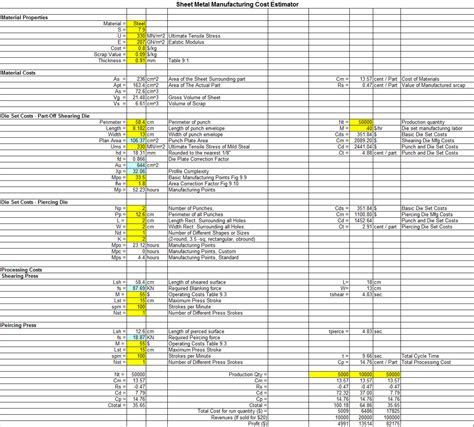

Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch. In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an .Accurate cost estimation is critical to sheet metal fabrication, ensuring that sheet metal fabrication projects are planned effectively, budgets are controlled, and profitability is optimized.

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle. Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.

Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical . Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch.

In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an estimator.Accurate cost estimation is critical to sheet metal fabrication, ensuring that sheet metal fabrication projects are planned effectively, budgets are controlled, and profitability is optimized. Cost Estimation of Sheet Metal Products. Today’s competitive markets require a sufficient understanding of cost structure for an adequate pricing strategy. There are several phases in the production cycle of sheet metal parts, including cutting, bending, roll forming, punching, welding, and more.

sheet metal production cost calculator

This sheet presents a method for the feature oriented quotation costing of sheet metal parts based on a specifically extended, cost oriented product model. The manufacturing of sheet metal parts in large scale production is mostly done with progressive dies.Cost of a sheet metal part comprises three major cost components such as material cost, processing cost and overheads. Determining accurate material cost has always been an issue. Theoretically material cost can be calculated as follows: Material Cost = Area of the flat pattern * thickness * (weight per unit volume) * cost per unit weight.Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle.

Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG. Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical .

Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch.

In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an estimator.Accurate cost estimation is critical to sheet metal fabrication, ensuring that sheet metal fabrication projects are planned effectively, budgets are controlled, and profitability is optimized. Cost Estimation of Sheet Metal Products. Today’s competitive markets require a sufficient understanding of cost structure for an adequate pricing strategy. There are several phases in the production cycle of sheet metal parts, including cutting, bending, roll forming, punching, welding, and more.

This sheet presents a method for the feature oriented quotation costing of sheet metal parts based on a specifically extended, cost oriented product model. The manufacturing of sheet metal parts in large scale production is mostly done with progressive dies.

sheet metal parts cost estimator

4 square box with metal stud bracket

4 metal octagon box 4012

Gray tile floors with variations of light and dark with white mixed in provide the perfect base for gray cabinets. You can choose a darker shade of gray, matched with greige (gray-beige) walls and white doors and counters, and a cream island for the perfect color palette for shaker-style cabinets.

costing of sheet metal parts|sheet metal production cost calculator