180 degree bend sheet metal Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This . Learn about the different types of electrical boxes, their uses, and installation requirements. Compare plastic, metal, and specialty boxes for indoor and outdoor applications.

0 · sheet metal bending dimensions

1 · sheet metal bending angle

2 · sheet metal bend size

3 · sheet metal bend chart

4 · sheet metal bend

5 · bending sheet metal

6 · 180 degree bending sheet metal

7 · 180 degree bending method

Following are the types of CNC machine: 1. CNC Lathe Machine. Lathe CNC machines are defined by their capability to turn materials during operation. They have less number of axes than CNC milling machines, making them shorter and more compact.

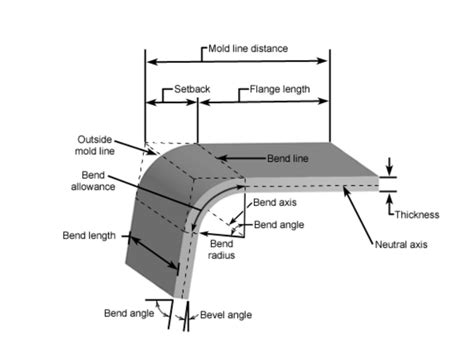

You can find your bend allowance with the following formula: (π/180) x B x (IR + K x MT) = bend allowance (BA), where B is the angle .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

sheet metal bending dimensions

sheet metal bending angle

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This .Remember, when using the tangent function for angle/2, ensure that your calculator is set to degrees. Many calculators default to radians. To convert from degrees to radians, multiply the angle by π/180. Conversely, for radians to . Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. . Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.

180°bending. The 180-Degree Bend Method: As shown in Figure 1-39, first fold the plate at a 30-degree angle using a 30-degree bending knife. Then, straighten the bend edge and finally, remove the backing pad. You can find your bend allowance with the following formula: (π/180) x B x (IR + K x MT) = bend allowance (BA), where B is the angle complementary to your desired bend angle (1 to 180 degrees), MT is the thickness of the material, IR is the inside radius, and K is the K-factor. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Then input the bend angle to get the arc length, bend allowance and bend deduction.Remember, when using the tangent function for angle/2, ensure that your calculator is set to degrees. Many calculators default to radians. To convert from degrees to radians, multiply the angle by π/180. Conversely, for radians to degrees, use a conversion factor of 180/π. Bend Radius is another crucial factor.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.

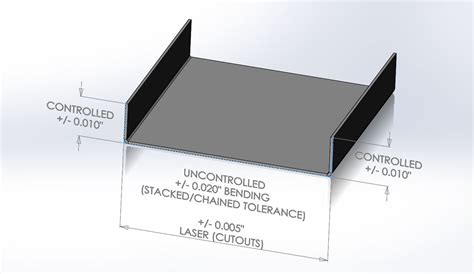

In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards.

180°bending. The 180-Degree Bend Method: As shown in Figure 1-39, first fold the plate at a 30-degree angle using a 30-degree bending knife. Then, straighten the bend edge and finally, remove the backing pad. You can find your bend allowance with the following formula: (π/180) x B x (IR + K x MT) = bend allowance (BA), where B is the angle complementary to your desired bend angle (1 to 180 degrees), MT is the thickness of the material, IR is the inside radius, and K is the K-factor. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

sheet metal bend size

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Then input the bend angle to get the arc length, bend allowance and bend deduction.Remember, when using the tangent function for angle/2, ensure that your calculator is set to degrees. Many calculators default to radians. To convert from degrees to radians, multiply the angle by π/180. Conversely, for radians to degrees, use a conversion factor of 180/π. Bend Radius is another crucial factor.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length.In this article, we offer a comprehensive guide to the best design practices for Sheet Metal Bending, tolerance guide and cost reduction tips. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness.

sheet metal bend chart

sheet metal bend

bending sheet metal

180 degree bending sheet metal

Do you have the best type of steel for your project? Use our chart to help & learn more about the various steel grades, their applications, & ASTM standards.

180 degree bend sheet metal|sheet metal bend chart