fusion 360 sheet metal flat pattern Solution: To convert the solid body to sheet metal. Navigate to the Sheetmetal tab. .

Types of Metal Roofing + Pros and Cons of Each. There are a number of different materials used for metal roofing, and three basic ways that it’s installed. These three different ways are referred to as the types of metal roofing. Hidden fastener metal roofing; Exposed fastener metal roofing; Stamped metal roofing

0 · mapboards pro fusion 360

1 · fusion 360 unfold sheet metal

2 · fusion 360 sheet metal drawing

3 · fusion 360 sheet metal design

4 · fusion 360 set material

5 · fusion 360 perforated sheet

6 · fusion 360 flange sheet metal

7 · fusion 360 bend flat body

The standard specifications of electrical machines are. 1. Standard ratings of machines . 2. Types of enclosure . 3. Standard dimensions of conductors to be used. 4. Method of marking ratings .

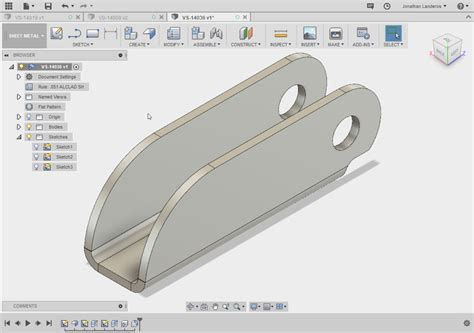

Sheet metal flat patterns. Use the Flat Pattern tool to create a flat pattern that you can use to create drawings of a sheet metal component for manufacturing in Fusion. A Flat Pattern is the .User's have asked how to create a flat pattern for a sheet metal part with a non .Use the Flat Pattern tool to create a flat pattern that you can use to create .

Solution: Follow the below steps to add the parts into existing drawing sheets. Go to .

This is the error I see on the flat pattern: "Error: FlatPatternAlign1(FlatPattern1) .Solution: To convert the solid body to sheet metal. Navigate to the Sheetmetal tab. . User's have asked how to create a flat pattern for a sheet metal part with a non-F3D format (for example: XT, SAT, STEP) that has been imported into Autodesk Fusion. Non-native parts are imported into Fusion as solids or .

Fusion 360 handles Flat Patterns and Unfold in very different ways. See what happens to a cutout in sheet metal in both the flat pattern mode and the unfold .Use the Flat Pattern tool to create a flat pattern that you can use to create drawings of a sheet metal component for manufacturing in Fusion. A Flat Pattern is the shape of the sheet metal component before it is formed. Solution: Follow the below steps to add the parts into existing drawing sheets. Go to Design from Drawing Sheet workspace. Create a Flat pattern in sheet metal workspace. Go to File and select New Dwarwing option. . Many Fusion 360 assembly contain multiple sheet metal components and their flat patterns. In this video I will show a workflow to place all of these flat patterns into a single .

The Fusion 360 Nesting Utility did a nice job of arranging sheet metal flat patterns for cutting in the manufacturing environment.

mapboards pro fusion 360

If I try and create a new base view in an existing drawing I don't get the option for flat pattern but if I go back to the sheet metal workspace and right click the component with the flat pattern I get the option there. This is the error I see on the flat pattern: "Error: FlatPatternAlign1(FlatPattern1) Compute Failed Failed to identify sheet metal faced for some edges. Ensure the body is a valid sheet metal body that keeps .

stainless steel bathroom cabinet manufacturer

Solution: To convert the solid body to sheet metal. Navigate to the Sheetmetal tab. Create > Convert to Sheetmetal. Select the Solid body. (Select the large face with even . I've also experienced this same problem with a few sheet metal parts. I've seen plat patterns work in drawings before but the last couple of parts I wanted to do drawings of the flat patterns I had to go in and create a sketch of . How to add flattened sheet metal parts into existing drawing sheets in Fusion 360 Follow the below steps to add the parts into existing drawing sheets. Go to Design from Drawing Sheet workspace. Create a Flat pattern in .

Unable to create a Flat Pattern of a bent sheet metal part in Fusion. One of the following occurs: When trying to select a face for the Flat Pattern, no faces can be selected on the part. The following message appears . How to export a flat pattern of sheet metal in STEP format in Fusion. This is needed to allow a flat pattern to be opened in third-party software. To export a flat pattern of Sheetmetal in STEP format in Fusion, follow the steps: Right-click on Flat Pattern and Activate it. From the top toolbar select Export Flat Pattern as DXF. Click OK. Select a location on the computer to save . Users reported that a sheet metal part that was converted from a solid (either imported from a STEP or designed with Solid modeling tools) cannot be unfolded or have a flat pattern created in Fusion. One of the following messages appears when trying to unfold the part or create a flat pattern: The selected stationary entity is not connected to any bends. Please .

fusion 360 unfold sheet metal

Flat patterns show bend lines, bend zones, center lines, and the shape of the entire sheet metal body with all bends flattened and bend factors considered. After you create a flat pattern, a Flat Pattern node is created in the Browser. You can switch between the folded state and the flat pattern state with the Activate Flat Pattern radio button. Then converted the copy into a sheet metal part and unfolded. One problem is you can't have a flat pattern and unfold the part. Unfolding then refolding the copy turns it back into the original part. The attached file has a valid flat pattern? don't know if it will be any use. Flat pattern

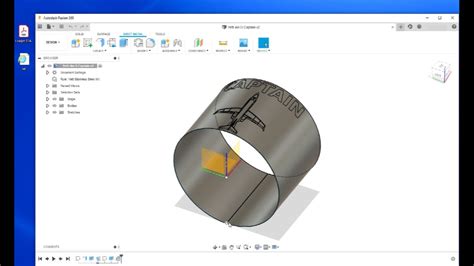

Hello, I have a work flow that HAS worked great where I use Sheet Metal components to design multi piece parts with intersecting curves. I then can make flat patterns from each of the Sheet metal components and cut on the CNC and get great results. I have spent the last few work days battling some really weird results however where there are issues . Creating a cone in sheet metal, which can be flattened for a pattern, is something you'll need to know a trick or two to do. Why? Well - Fusion 360's math as.

In order to convert it to sheet metal, I had to extrude a small flat section in the back, as fusion would not allow just the curved section to be converted. The problem, as seen in the third screenshot, is that the flat pattern created from the converted sheet metal parts are not flat. Somewhere along the way, fusion fails to fully flatten the .

Have a tricky question about a Fusion (formerly Fusion 360) feature? Share your project, tips and tricks, ask questions, and get advice from the community. . Check out the process in the Screencast. I did the sheet metal part folded on one sheet, flat pattern on another and also folded and flat pattern on the same sheet. John Hackney, Retired The Fusion 360 Nesting Utility did a nice job of arranging sheet metal flat patterns for cutting in the manufacturing environment. When the Nesting Utility .

Many Fusion 360 assembly contain multiple sheet metal components and their flat patterns. In this video I will show a workflow to place all of these flat pa. Hi There, I'm new to Fusion 360 and came across a problem in making a sheetmetal product. For some components in my design I'm not able to make a flat pattern and for some of them I am able to. I can't figure out why some of them don't work. I got the following message: Error: FlatPatternAlign1(FlatPattern1)Compute Failed. I tried changing the the .

Unfortunately, you have to use sheet metal features to create the base model to be able to use sheet metal-specific features like Unfold or the Flat Pattern tool. Using the Flange function to make the bodies guarantees that you have sheet .

fusion 360 sheet metal drawing

Is it possible to create a drawing that has both view fold and the unfolded sheet metal view in the same drawing in Fusion 360? Add both the Flat Pattern and the Folded Model in the drawing views. Create a flat pattern . The sheet metal component contains multiple sheet metal bodies. However, only one body is flattened while creating a Flat Pattern in Fusion. Currently this is a limitation when working with sheet metal components in Fusion. Create only single body sheet metal components to avoid issue. Copy and paste new the sheet metal component. Then delete extra bodies so .

Multiple sheet metal bodies exist, but it is desired to have a single flat pattern for all the bodies. To combine sheet metal body and unfold, do the following: Create a bend using SHEET METAL > CREATE > FLANGE. Combine the Bodies using SOLID > MODIFY > COMBINE. Unfold the sheet metal using SHEET > MODIFY > UNFOLD. If sheet metal bodies . Users reported that a flat pattern of a folded sheet metal part in Fusion does not have the same orientation as the original part. When creating it, it is rotated 180 degrees or at a random angle. The resulting DXF file also reflects the incorrect orientation. "Create Flat Pattern" finds the ‘longest edge’ on the flattened body and aligns that longest edge to the positive X .

How to export a DXF of a sheet metal part in Fusion To create a DXF for a sheet metal component in Fusion Create a flat pattern of the sheet metal component. From the flat pattern, click the EXPORT drop-down from the Ribbon bar. Select Export Flat Pattern as DXF

One way is to create the Component from the start as Sheet Metal. This allows you to assign the sheet metal rule up front. Second way is to Create a Standard Component and then create a sheet metal feature in that component. The Third way is to convert a Sheet Metal Body into a Sheet Metal Component. This Blog Article and Video will show you . Learn how to layout box designs in Fusion 360. We’ll take a look at utilizing the sheet metal tools, so you can export the 2D pattern as a DXF file for your . This is the Autodesk Inventor Professional forum, not the Fusion 360 forum. In any case, you select the Flat Pattern command rather than the Unfold command and then create a 2D drawing of the Flat Pattern. File>Export and then Attach Your *.f3d file .

stainless steel backflow enclosure

The good news is, yes, you can definitely create a folded and flat pattern drawing view in the same sheet. To do this, you need to create a flat pattern within your design first. However, it looks like you're missing a few tools from the Sheet Metal toolbar; one of which is the Create Flat Pattern tool. An STP model was imported into Fusion 360 and converted into a sheet metal component by following the steps from the article How to create flat pattern in Fusion 360 for a sheet metal part imported from another software. When attempting to convert the component into a flat blank, the stationary face would not select and the model does not turn into a flat pattern.I am new to sheet metal, and am trying to model foam as a sheet metal. I made a new rule based on steel and changed its thickness to 0.5 inches, and its k-factor to 0.0296 based on research I found. But the flanges that bend towards each other never want to be snug. I confirmed that it is a sheet metal component (the icon on the body of the component). When I choose to Create/Create Flat Pattern, I choose the edge that the YouTube creator chooses and it creates a "Flat Pattern" with no errors, except that it isn't flat! The flat pattern view shows the cone in 3D perspective in a different orientation.

stainless steel bento box lunch box

What are Different Types of Metal Fabrication Process? Metal fabrication involves different processes such as cutting, casting, folding, welding, machining, punching, shearing, and stamping. Let's know in detail about these metal fabrication processes - 1. Cutting. It is the most commonly used metal fabrication process.There are several careers in the metal industry that involve handling, managing or creating metal products. Some of these jobs require cutting or welding materials, while others require managing a company's .

fusion 360 sheet metal flat pattern|fusion 360 unfold sheet metal