cnc machine axis Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems. Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops e.

0 · cnc with rotary axis

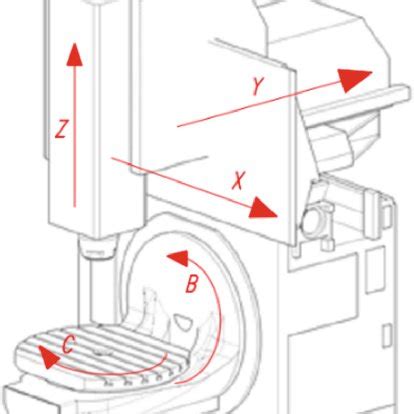

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

The term "gauge steel" is often used to refer to the thickness of sheet metal made of steel. Understanding these nuanced differences is vital when consulting a metal gauge chart to ensure that you're selecting the appropriate material for your endeavor.

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the .

Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

cnc with rotary axis

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). When we refer to the axes of a CNC machine, we’re essentially delving into the spatial dimensions along which the machine can move and operate. Each axis represents a specific direction, and the combination of these axes dictates the machine’s ability to maneuver and shape raw materials.

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.

All machines start with three axes. The three axes model performs essential functions and, in the hands of an experienced machinist, can be used for more advanced creations. Four axes on a CNC machine add an extra cutting direction, which increases precision.

cnc machine axis locations diagram

Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

When we refer to the axes of a CNC machine, we’re essentially delving into the spatial dimensions along which the machine can move and operate. Each axis represents a specific direction, and the combination of these axes dictates the machine’s ability to maneuver and shape raw materials. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.

cnc machine axis direction

char broil stainless steel 4 burner barbecue with cabinet reviews

chassis metal bracket bottom mustang 2016

The proper installation and use of junction boxes are paramount for a safe and efficient electrical system in your home. By understanding the function of junction boxes, using the right tools and materials, following a step-by-step .

cnc machine axis|cnc with rotary axis