metal sheet cutting design Start your first SendCutSend project today! Upload your CAD design, or try one of our customizable part templates to get a instant pricing on your custom laser cut parts. All . Lancing is a type of punching operation where the workpiece is sheared and bent with one strike of the lancing tool. It creates features like tabs, vents, and louvers in sheet metal workpieces. The nibbling process involves cutting a sheet metal .

0 · sheet metal layout techniques

1 · sheet metal fabrication standards

2 · sheet metal fabrication laser cutting

3 · sheet metal fabrication design guide

4 · sheet metal diagram fabrication

5 · sheet metal basic design guidelines

6 · basics in sheet metal design

7 · 24x24 sheet metal laser cutter

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.Junction boxes help to protect wires from the elements and mechanical stress, ultimately extending the lifespan of your electrical system. By preventing corrosion, physical damage, and exposure to moisture, junction boxes keep your wiring in better condition for longer.

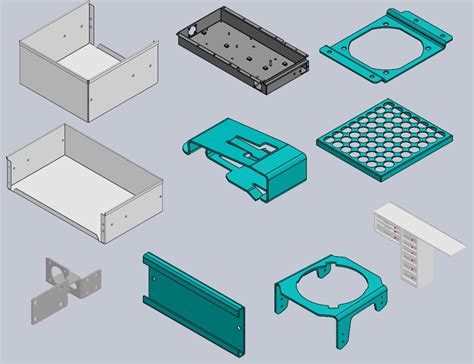

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, .Start your first SendCutSend project today! Upload your CAD design, or try one of our customizable part templates to get a instant pricing on your custom laser cut parts. All .Agwey Metal Designs, Inc. offers custom metal stamping, precision sheet metal fabrication, and waterjet cutting services. Search. Skip To Content. [email protected] 508.747.1037. 508.747.1037 .Sheet metal design involves more than simply bending and cutting sheets of metal. It is about imagining a product and its purpose and bringing it into reality with precision and passion. We don’t only create metal components at .

Applications of Laser Cutting in Sheet Metal Cutting: Produces highly accurate and clean cuts, perfect for detailed designs. Capable of cutting through various metal types and thicknesses, including steel, aluminum, and .1st Cut Designs & Metal Work provides commercial metalwork design services like metal fabrication & laser cutting. . Materials; Contact (954) 410-8501. Metal Fabrication Made Easy. Offering Metal Design Services. Request A Free Quote. USA Based Sheet Metal Design Business . Design. Metal Platforms. Metal Bending. Laser Cutting. Check Out Our .

After the design phase, the sheet metal is then cut and formed to match the specifications laid out in the design. The cutting process can be done using various methods, including laser cutting, plasma cutting, or waterjet cutting. The forming process, on the other hand, can involve metal stamping, progressive die stamping, deep draw stamping . Generally, Sheet metal cutting refers to splitting a single metal sheet into two or more pieces.But, it also involves the removal of unwanted parts from a sheet using shear force, heat, or any other form of energy. The cutting process requires high pressure at the cutting position, which can fracture the sheet from the designated area to create the desired shape.

1 16 tamiya tiger inner chassis metal replacement

Prepare your files easily with our Design Guidelines for laser cutting metal parts From 1 to 10.000 Parts Instant Quote 72 h Shipping | LaserBoost. . At LaserBoost, we perform sheet metal laser cutting using the latest cutting-edge technology from Trumpf™. Our expert team combines different types of gases and specific machine configurations .

Surfaces Find the ideal combination of style and toughness with our innovative sheet metal finishes for stainless steel and aluminium. Hairline; Sandblasted; Mirror; Satin; Vibration; Liquid Metal; PVDF Coated; Anodized; Patterns We can make metal sheets and plates in many nice looks, designs, and shapes. Pretty patterned sheet metal shapes . The Role of Laser Cutting in Metal Artwork. Cutting the design on the sheet metal can be done by manually operating the laser cutter or hooking it to CNC laser cutting machines (Computer Numerical laser cutters). CNC control of a laser cutting machine is .Sheet metal laser cutting design is a game-changer in the metal fabrication industry. It combines precision and speed, making it an essential technique for creating complex metal components. In this guide, you’ll learn about the basics of sheet metal laser cutting, its benefits, the technology behind it, and practical design tips to maximize .

Metal sheet cutting designs have revolutionized the manufacturing industry by empowering businesses to create products that are not only functional but visually appealing as well. The ability to customize designs, improve efficiency, and explore versatile applications has elevated the manufacturing industry to new heights. As technology .

UNISTAR CNC Fiber Laser Cutter can cut all kinds of metal plates, pipes, and is mainly used for rapid cutting of stainless steel, carbon steel, manganese ste.Laser cutting perforated metal panel is such a dramatic type of decorative metal material for architectural decor. We adopt a high power density laser beam to irradiate the materials. As the laser beam moves over the sheet, the hole continuously forms a slit having a narrow width (e.g., about 0.1 mm) to complete the cutting of the material.Sheet metal fabrication takes thin, flat, and bendable sheets of different types of metal and cuts, bends, and assembles them into a variety of products. 9/2/2021 PDF File

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Learn about the GrabCAD Platform . Sheet metal cutting Sheet metal cutting / Loading . BanPhaDai.x_t. x_t. November 24th, 2020 BanPhaDai.stp. stp. November 24th, 2020 Capture2.PNG. png. .Type of Machine: CNC Laser Cutting Machine: Material: Mild Steel: Type of Cutting: Laser Cutting: Accuracy: 0.02: Maximum Dimension: 1500*3000 mm: Maximum thicknessLaser cutting designs. In this category there are dwg files of drawings for laser cutting. Various types of drawings useful for the design or construction of gates and railings with pantographed sheet metal inserts. We offer various shapes .

The machine was operated continuously to analyze its performance. Keywords: Pneumatic, Sheet Metal, Cutting, Machine, Design, and Fabrication I. INTRODUCTION The sheet metal cutting operation is a main part of industries and most of them are manual i.e. hand-operated, so we came with an idea of automation of this machine by using the 555 IC .

Browse 2,014 incredible Laser Cutting Metal vectors, icons, clipart graphics, and backgrounds for royalty-free download from the creative contributors at Vecteezy! The science behind metal bending and cutting techniques is a blend of material behavior, tool design, and process optimization. Understanding the underlying principles enables engineers and manufacturers to manipulate the properties of metal sheets to create a vast array of components and structures.

We've compiled our best tips into this guide to help you understand the laser and sheet cutting processes, . Design Guide: Laser and Sheet Cutting . Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more. . The sheet metal cutting machine is the heart of small scale sheet metal industries. . The objective is to design and development of automatic sheet metal cutting machine to reduce the manpower .

Sheet metal design plays a vital role in various industries, including automotive, aerospace, and manufacturing. Creating precise and efficient designs requires a thorough understanding of the process of preparing files for cutting machines. This article explores the key aspects involved in preparing sheet metal design files for cutting machines, highlighting the .Find and save ideas about laser cut steel on Pinterest.

sheet metal layout techniques

Sheet metal nibbling process. Nibbling is a sheet metal cutting technique that involves removing material incrementally. Nibbling allows for intricate patterns, curves, and shapes by creating overlapping holes or notches. Instead of cutting through the material in one go, nibbling makes multiple, small, and controlled cuts to achieve the .Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge . Using a DXF will create a quote for a “flat cut” sheet metal part without bends. If there are bends in the part, the best way to quote is by using a 3D CAD model. .Our laser cutting service offers a variety of metal materials to choose from. Upload a 3D CAD file to get an online quote today. Parts ship in as fast as 1 day. . Sheet Metal Design Guide. Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material.

1 1 4 inch metal flag pole bracket

sheet metal fabrication standards

sheet metal fabrication laser cutting

What Metals Are Used in Residential Building Construction? 1. Carbon Steel. Home-building professionals often use carbon steel for framing houses. Combining a high level of carbon with .

metal sheet cutting design|sheet metal fabrication design guide