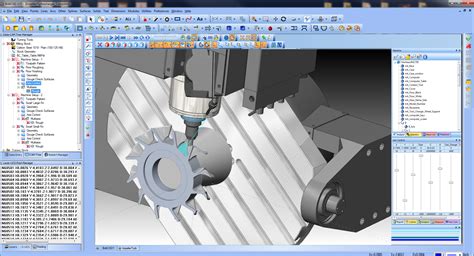

cad cam cnc machine manufacturing Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G-code, and CNC machines to turn 3D CAD models into products. Tagging of the junction box, cables, and cable drums is very important during front-end engineering design for the preparation of the JB schedule, cable schedule, cable drum schedule, etc. In this article, we are going to discuss the .

0 · what is cad cam software

1 · cnc cad software for beginners

2 · cam software for cnc

3 · cam programs for cnc machines

4 · cad cam software for cnc

5 · cad cam cnc software free

6 · best cnc cad cam software

7 · autodesk cad cam for manufacturing

Recessed lighting is a light fixture installed into a ceiling concealing the light bulb and the housing. The light bulb and housing sit flush inside the ceiling. This lighting is also known as can lights or downlights.

CAM software takes the CAD design and generates toolpaths and instructions for CNC (Computer Numerical Control) machines, 3D printers, and other manufacturing equipment. It determines .Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G .Autodesk Fusion for Manufacturing is a more capable version of Fusion that . Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G-code, and CNC machines to turn 3D CAD models into products.

CAM software helps designers plan, visualize, and simulate their manufacturing processes, improving accuracy and efficiency in operations such as CNC machining. Onshape’s CAM Studio offers high-quality CNC strategies to make .CAM software takes the CAD design and generates toolpaths and instructions for CNC (Computer Numerical Control) machines, 3D printers, and other manufacturing equipment. It determines how to cut, shape, or build the physical object based on the digital model. Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G-code, and CNC machines to turn 3D CAD models into products.CAM software helps designers plan, visualize, and simulate their manufacturing processes, improving accuracy and efficiency in operations such as CNC machining. Onshape’s CAM Studio offers high-quality CNC strategies to make just about any part.

Autodesk Fusion for Manufacturing is a more capable version of Fusion that provides additional, advanced CAM capabilities for CNC machining (milling and turning), sheet-based nesting and fabrication, and 3D printing in a range of materials.NX CAM software helps you generate efficient toolpaths, simulate machining operations and output production-ready programs for a wide range of computer numerical control (CNC) machines. Additionally, you can prepare part models and define machine setups using the integrated CAD capabilities. CAD/CAM enables designers and engineers to create precise 2D and 3D models. CAM automates and controls manufacturing processes based on CAD designs. CNC technology programs and controls machine movements in the manufacturing process. The integration of CAD/CAM and CNC improves precision, efficiency, and cost-effectiveness.Computer-aided manufacturing (CAM) software utilizes NC software to generate G-code, instructing CNC machines for precise part manufacturing.

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or products, while CAM translates these designs into machine-readable instructions for CNC equipment.CAD/CAM software is used to translate computer-aided design (CAD) to manufacturing workpieces with computer-aided manufacturing (CAM) on your CNC machine. Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex. With CAD/CAM, the CNC machines can run tests, simulate the prototype and start machining faster than ever before! Managing manufacturing projects requires a high level of visibility to maximize efficiency. CNC CAD CAM allows you .

CAM software takes the CAD design and generates toolpaths and instructions for CNC (Computer Numerical Control) machines, 3D printers, and other manufacturing equipment. It determines how to cut, shape, or build the physical object based on the digital model.

what is cad cam software

Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G-code, and CNC machines to turn 3D CAD models into products.CAM software helps designers plan, visualize, and simulate their manufacturing processes, improving accuracy and efficiency in operations such as CNC machining. Onshape’s CAM Studio offers high-quality CNC strategies to make just about any part.Autodesk Fusion for Manufacturing is a more capable version of Fusion that provides additional, advanced CAM capabilities for CNC machining (milling and turning), sheet-based nesting and fabrication, and 3D printing in a range of materials.

NX CAM software helps you generate efficient toolpaths, simulate machining operations and output production-ready programs for a wide range of computer numerical control (CNC) machines. Additionally, you can prepare part models and define machine setups using the integrated CAD capabilities. CAD/CAM enables designers and engineers to create precise 2D and 3D models. CAM automates and controls manufacturing processes based on CAD designs. CNC technology programs and controls machine movements in the manufacturing process. The integration of CAD/CAM and CNC improves precision, efficiency, and cost-effectiveness.Computer-aided manufacturing (CAM) software utilizes NC software to generate G-code, instructing CNC machines for precise part manufacturing. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are distinct yet complementary technologies in the CNC machining process. CAD focuses on creating digital 3D models of parts or products, while CAM translates these designs into machine-readable instructions for CNC equipment.

CAD/CAM software is used to translate computer-aided design (CAD) to manufacturing workpieces with computer-aided manufacturing (CAM) on your CNC machine. Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex.

cnc cad software for beginners

cam software for cnc

cam programs for cnc machines

These fabrics were known as ‘Cloth of gold’. Today, lame fabric can be made with metallic fibers for exclusive garments and metal coated plastic for more affordable ones. Moreover, synthetic fibers make the fabric lightweight, and easier to care for and handle it when sewing.

cad cam cnc machine manufacturing|best cnc cad cam software