best welder for thin sheet metal What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or . Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se.

0 · welding sheet metal with mig

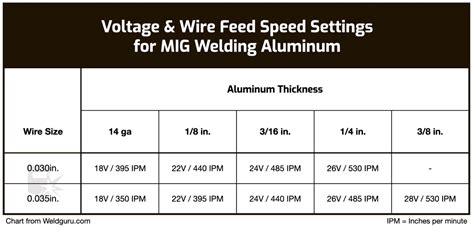

1 · mig welding travel speed chart

2 · mig welding thin steel

3 · mig welding thin sheet metal

4 · mig welding settings

5 · mig welding parameters

6 · mig settings

7 · how to weld thin steel

The appropriate wire used for a junction box is typically an enclosed Romex wire that runs through the sub-panel or main electrical panel. This wire is commonly color-coded, with black denoting heat, white serving as the neutral channel, and copper or green wire used for grounding the connection.

TIG and MIG welding are the preferred option, and since this machine can handle both, it’s a great choice for those working with thin sheet metal. It can handle sheets as thick as ¼’’, which is ideal for a lot of basic projects. What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or . In our opinion, the PRIMEWELD TIG225X is the best welder for sheet metal. It’s a TIG welder for everyday buyers for sheet metal welding and has a good range of settings with .

5.009.999.999.00

welding sheet metal with mig

9.00 To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or . You can use mig welders as spot welders, just drill a small hole in the area to be spot welded then weld a spool in it.Works well with aluminum, stainless steel, and thinner metals. It needs 110/220 volts to work and uses 7018 and 6013 welding rods. Looking for a welder that can handle any job? Then you need the Hobart 500559 Handler 140 MIG Welder.

The machine can be adjusted between 15 and 250 Amps to allow welding anything from thin gauge sheet metal up to ½ inch. And, like more expensive machines, this .

mig welding travel speed chart

1.14,499.97

0.00,051.00

,999.00,049.00,051.00

metal keypad housing

5.97 Squeeze-type spot welders have large metal electrode jaws which go either side of the metal sheets, creating heat and pressure in a small spot to weld them together. Battery spot welders have electrodes on the same side .

Hi to everyone I'm new to welding end the forum looking for advise I want to by welder mainly for thin sheet metal and bodywork I'm looking at few options can you give your advice and opinion Lincoln Power Mig 180C ; Lincoln Electric Powertec 191c Mig Welder ;Millermatic 180 and Portamig 185 your opinion is appreciated thanks Then I came across this video from a guy who tested out the Parkside PMSG 200 A1 welder on thin sheet metal 0.7mm thick, which is probably what I'll be using to repair rust spots on my car. The Parkside PMSG 200 A1 seems like a nice little unit with some nicer features over the Ipotools MIG 160 er: it has a detachable euro plug and can also .You can see what's happened from the photograph. The puddle of molten metal has become so big and heavy it's dropped off the steel. Often this can be prevented by reducing the amp setting of the welder and the wire speed. Using thinner wire (0.6mm instead of .

Re: Best Pulse Mig for Thin Sheet Metal Cost no object, for GMAW-P capabilities, the Lincoln S350 with the 25M feeder is the hot ticket. STT serves virtually no practical purpose outside of open root pipe, and much of the design basis for that was pretty limited (closure spools on high energy pipe being the main focus). You are simultaneously trying to conquer the toughest things for a beginner welder: thin material, round tubing, gas-less flux core (which is typically not used on <1/16"), and limited adjustability on the welder. Gas-less flux core is generally regarded as a "hot" process which is why it's not easy to run on thinner material. Hi, I consider buying a cheap chinese tig-welding inverter, which has a 5 to 200 Amps range. I want to weld thin automotive steel, thicknesses will be in the gauge range 11 to 22. The welder is nothing special, just a 0/200 job straight from China. The brand is Chicago Electric. Its a 60-90 Amp welder, and I'm using 0.030" mild steel flux core wire. There is a spare tip, but I gave the one in use a good cleaning instead. Its a fine starter hobby welder, but I've see its limitations already.

metal l shelf brackets

Hi, For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. with thin metal often you have to stop after 2 or 3 inches and let it cool off or you will burn a hole in it. and thin metal it is important to have many tack welds every few inches as joint gap can increase as you are welding. 1/8 thick material i would use 1/8 6013 at about 90 amps if fillet welding in flat position. or 3/32 6013 at 80 amps. The Clarke was easier on thin metal as it was set up for it. The Miller took some tweaking with the adjustable inductance to work well. There is more than just OCV. The Clarkes have something like 18V. With my Miller or DIY welder on 18V, it will be about 80A with 0.8mm wire. The difference is the volts/amps curve. Hi to everyone I'm new to welding end the forum looking for advise I want to by welder mainly for thin sheet metal and bodywork I'm looking at few options can you give your advice and opinion Lincoln Power Mig 180C ; Lincoln Electric Powertec 191c Mig Welder ;Millermatic 180 and Portamig 185 your opinion is appreciated thanks

Then I came across this video from a guy who tested out the Parkside PMSG 200 A1 welder on thin sheet metal 0.7mm thick, which is probably what I'll be using to repair rust spots on my car. The Parkside PMSG 200 A1 seems like a nice little unit with some nicer features over the Ipotools MIG 160 er: it has a detachable euro plug and can also .You can see what's happened from the photograph. The puddle of molten metal has become so big and heavy it's dropped off the steel. Often this can be prevented by reducing the amp setting of the welder and the wire speed. Using thinner wire (0.6mm instead of . Re: Best Pulse Mig for Thin Sheet Metal Cost no object, for GMAW-P capabilities, the Lincoln S350 with the 25M feeder is the hot ticket. STT serves virtually no practical purpose outside of open root pipe, and much of the design basis for that was pretty limited (closure spools on high energy pipe being the main focus).

You are simultaneously trying to conquer the toughest things for a beginner welder: thin material, round tubing, gas-less flux core (which is typically not used on <1/16"), and limited adjustability on the welder. Gas-less flux core is generally regarded as a "hot" process which is why it's not easy to run on thinner material. Hi, I consider buying a cheap chinese tig-welding inverter, which has a 5 to 200 Amps range. I want to weld thin automotive steel, thicknesses will be in the gauge range 11 to 22. The welder is nothing special, just a 0/200 job straight from China. The brand is Chicago Electric. Its a 60-90 Amp welder, and I'm using 0.030" mild steel flux core wire. There is a spare tip, but I gave the one in use a good cleaning instead. Its a fine starter hobby welder, but I've see its limitations already.

Hi, For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. with thin metal often you have to stop after 2 or 3 inches and let it cool off or you will burn a hole in it. and thin metal it is important to have many tack welds every few inches as joint gap can increase as you are welding. 1/8 thick material i would use 1/8 6013 at about 90 amps if fillet welding in flat position. or 3/32 6013 at 80 amps.

mig welding thin steel

Wiring a double switch box is a common task for homeowners and electricians alike. A double switch box, also known as a two-gang switch box, allows you to control two separate electrical devices or circuits from a single location. This can be useful in areas where you want to control multiple lights or appliances from one convenient switch.

best welder for thin sheet metal|welding sheet metal with mig