cnc lathe machine insert The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. By your description, you're doing a dry run. It's just a term used to describe running the program through, but not cutting a part. Most machines have a "dry run" button on them, that when turned on, allow you to "rapid" through the slow feed parts of your program. It just speeds up the process of a dry run.

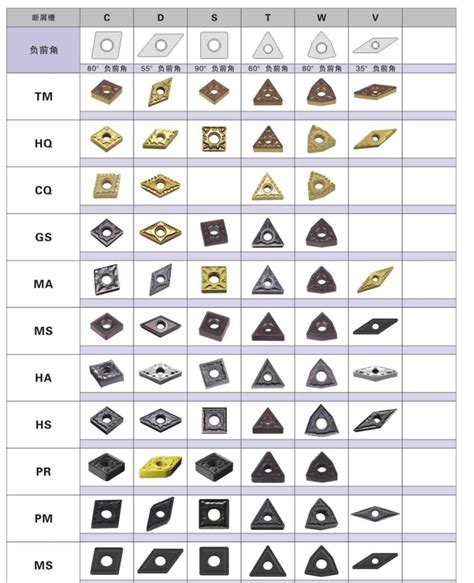

0 · types of machining inserts

1 · types of lathe inserts

2 · cnc turning insert size

3 · cnc lathe turning insert

4 · cnc insert shapes

5 · cnc cutting insert shape

6 · best lathe inserts

7 · best lathe insert for turning

Sheet metal blanking is a critical process in metal fabrication that involves the cutting or shearing of a shape from a metal sheet. This method plays a significant role in industries such as automotive, aerospace, and .

There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining .

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC .The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness. Choose the insert style (shape and size) .

There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency.The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness. Choose the insert style (shape and size) based on the . In this post, we will focus on the “go-to” workhorse insert shapes that are the most popular for job shop CNC turning operations: As a quick note: when referring to the number of edges on an insert, we will use the count for double-sided negative rake inserts.

Discover a comprehensive range of lathe cutting tools, including turning inserts, threading inserts, boring bars, cermet turning inserts, CBN turning inserts, notch grooving & threading tools, micro turning tools, and more. Our high-quality tools are designed for precision, durability, and optimal performance in all your turning operations. CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .In CNC turning, the selection of the right type of insert is crucial for achieving optimal results. Carbide inserts are versatile and widely used for various applications, while ceramic, coated, CBN, and PCD inserts offer specific advantages for machining different materials.

Learn the essential parameters of ISO nomenclature for selecting CNC inserts efficiently. Focus on key factors to streamline insert selection for optimal machining performance.In this comprehensive guide, we will dive deep into the world of CNC turning inserts, explore the different types, materials, and coatings available, and provide essential tips on how to choose the right insert for optimal efficiency.Cutting inserts are divided into different types. This division specifically relates to the material they are made, its shape, dimensions, and applications. The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts.There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. CNC lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency.The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness. Choose the insert style (shape and size) based on the .

types of machining inserts

In this post, we will focus on the “go-to” workhorse insert shapes that are the most popular for job shop CNC turning operations: As a quick note: when referring to the number of edges on an insert, we will use the count for double-sided negative rake inserts.Discover a comprehensive range of lathe cutting tools, including turning inserts, threading inserts, boring bars, cermet turning inserts, CBN turning inserts, notch grooving & threading tools, micro turning tools, and more. Our high-quality tools are designed for precision, durability, and optimal performance in all your turning operations. CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .In CNC turning, the selection of the right type of insert is crucial for achieving optimal results. Carbide inserts are versatile and widely used for various applications, while ceramic, coated, CBN, and PCD inserts offer specific advantages for machining different materials.

metal fabrication gta

Learn the essential parameters of ISO nomenclature for selecting CNC inserts efficiently. Focus on key factors to streamline insert selection for optimal machining performance.In this comprehensive guide, we will dive deep into the world of CNC turning inserts, explore the different types, materials, and coatings available, and provide essential tips on how to choose the right insert for optimal efficiency.

metal fabrication glens falls

types of lathe inserts

cnc turning insert size

The RACO« four-inch, two-gang, Square Galvanized Steel Electrical Handy Box is 2-1/8 inches deep. It features 1/2- and 3/4-inch knockouts. Compare - We've selected these .

cnc lathe machine insert|types of machining inserts