sheet metal bending allowance chart Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor. A wholesale distributor plays a vital role in connecting manufacturers and retailers and facilitating the transfer of goods between distribution channels. To demystify this model, we'll explain how wholesale distribution works and why it's important to find a reliable wholesale fulfillment provider. What is wholesale distribution?

0 · stainless steel bend allowance chart

1 · sheet metal bending allowance formula

2 · sheet metal bend tolerance chart

3 · sheet metal bend deduction chart

4 · sheet metal bend allowance table

5 · how to calculate bending allowance

6 · calculating bend allowance sheet metal

7 · bend allowance chart pdf

PVC Electrical Junction Boxes are surface mounted enclosures without entrance hubs which allows multiple conduits to be connected and wire splices made within. All junction boxes include cover and mounting screws and may or may not include mounting feet, depending on the size.

This data is essential for accurately determining the unfolded or flat dimensions of sheet metal parts before bending. By incorporating bend allowance into their calculations, mold designers can predict the final dimensions of a .Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.

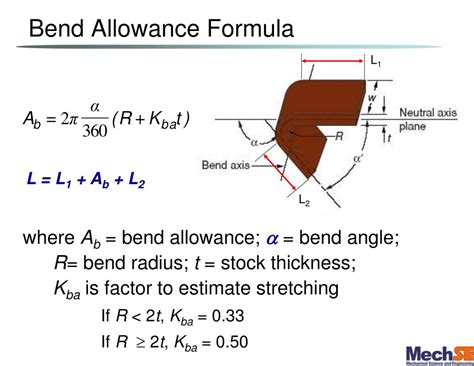

Calculate the accurate bend allowance for your sheet metal fabrication with our easy-to-use calculator. Get precise measurements and . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors . Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to .

This is a step-by-step guide. First, you need to determine the radius and bend angle. Use the following formula: Bend allowance = (p/180 x Bend angle x (Radius x K-Factor + Thickness). Angle is a critical component in calculating .

Bend Allowance Formula. The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to .The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the . 3 Sheet Metal Bend Gains Chart. 3.1 BEND GAINS CHART DOWNLOAD; 4 Sheet Metal Bend Gains FAQ. 4.0.1 What is a sheet metal bend gain, and why is it important in sheet metal fabrication? 4.0.2 Why should .

Calculate the accurate bend allowance for your sheet metal fabrication with our easy-to-use calculator. Get precise measurements and reduce waste. Close; Articles Metalworking. . 0° – 180° Bend Allowance Chart for .

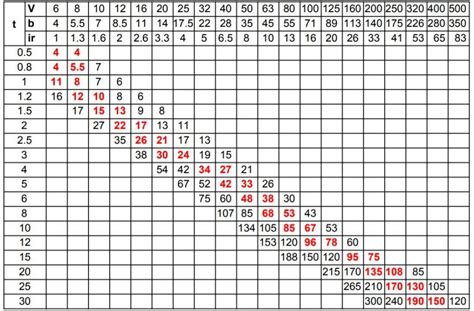

Press brake bend allowance refers to the additional material length required for a given bend angle in a metal sheet or plate when using a press brake. When . Bending allowance chart for cold rolled steel sheet SPCC (electro-galvanized sheet SECC) TV: Angle: 0.6: 0.8: 1: 1.2: 1.5: 2: 2.5: 3: 3.5: 4: 4.5: 5: To enhance the readers’ understanding of basic concepts in sheet metal design calculation, the following points will be summarized and explained:. The definitions of the two bending algorithms: bend allowance and bend deduction, and their connection to the actual sheet metal geometry. The relationship between bend deduction and bend allowance, and how . We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material. We discussed the bend allowance and bend deduction calculation in a previous article. The bend deduction is often confused with bend allowance. Thus, understanding the bend allowance or bend deduction is a crucial first step to understanding how sheet metal parts are fabricated for the metal forming and fabricating industry. 1.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.

where: BA is the bend allowance; B< is the bend angle; IR is the inside radius; MT is the material thickness; The K-Factor is a dimensionless value and typically ranges between 0 and 0.5 for most sheet metal materials and bending operations. Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into:An Air Bend Force Chart, or Force Chart breaks down a number of key components of sheet metal bending in an easy to reference format. Being able to read a bend force chart is crucial for any Brake Press operator and sheet metal engineer. The gauge, inside radius, die opening, and minimum flange length are all interconnected through different equations and relationships, the .

With this chart, you can save time and increase efficiency in your bending process.. Additionally, our press brake tonnage calculator can assist you in calculating the required bending force for your specific sheet metal product.. We understand the importance of selecting the most appropriate V-opening, and our chart shows the optimum relationship between metal thickness .

0° – 180° Bend Allowance Chart for Sheet Metal Bending; Sheet Metal Bending: Everything You Should Know Explained; Metal Bending: The Ultimate Guide; 28 Sheet Metal Bending Problems and Solutions. Don't forget, sharing is caring! : ) Share. Facebook. Twitter. LinkedIn. Reddit. VK. Email. Print.

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend . Here the role of Sheet Metal bend Allowance comes into the picture. Bend Allowance and Bend Deduction both values can be used to calculate the size of the flat pattern. But in this article, I will just cover the first . The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal. However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending .

In such cases, the steel plate bending radius and sheet metal bending force calculation also become paramount. There's also the issue of time. Corrections take time, especially if you're dealing with large-scale projects. . Bending Allowance Chart for Cold Rolled Steel Sheet SPCC (Electro-Galvanized Sheet SECC) TV Angle 0.6 0.8 1 1.2 1.5 2 2. .The Sheet Metal Bend Allowance Chart is an essential tool for engineers, designers, and fabricators in the sheet metal industry. By providing accurate data for various material thicknesses, bend radii, bend angles, and K-factors, the chart enables precise calculations and minimizes material waste. With careful attention to the parameters and .Key Features. Accurate Calculations: Provides precise bend allowance and bend deduction values. User-Friendly Interface: Simple and intuitive design for easy use. Automatic Calculation: Real-time updates as you input values. Versatility: Suitable for various sheet metals, including stainless steel and aluminum. Benefits of Using Our Calculator. Enhanced Accuracy: Minimize .

Sheet Metal Bend-Allowance - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or read online for free. The document contains a bend allowance chart with bend allowance values for various sheet metal gauges from 8 to 24 gauge, bend angles from 10 to 170 degrees, and K-factors of 0.33. The bend allowance is calculated as the angle in radians .How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°.The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness. Sheet metal parts are usually fabricated from a single sheet of .

stainless steel bend allowance chart

Bend Allowances for Sheet Metal Air Bends (MILD STEEL ONLY) R(M) V R(T) T L1 BA L2 R(M) V R(T) T L1 BA L2 . For gaging, remember to use only one leg and one-half of the bend allowance to approximate the distance. AE-103 (07/2017) Created Date: 7/21/2017 11:32:44 AM .

In this tutorial, learn the difference between SOLIDWORKS Sheet Metal bend calculations including k-factor, bend allowance, and bend deduction with examples. The Bend Allowance (BA) is the arc length of bending measured along the neutral axis of the metal plate since the length of the neutral axis does not change after bending. Once the bend allowance is calculated, it should be added to the flat length to determine the required sheet metal length needed to form the desired workpiece.

junction box ds-2de4a series cameras

junction box electrical size

Receive precisely crafted CNC machined aluminum parts from an industry leader since 1975. Why choose Moseys for your CNC aluminum parts needs? High-precision machining capabilities –producing custom aluminum parts from .050” diameter to a 24” cube.

sheet metal bending allowance chart|calculating bend allowance sheet metal