cnc machine cell If you’re looking to add automation to your CNC machining processes, we can help bridge the gap. We’re a team of machinists, with expertise in CNC robotics. We understand both the challenges and opportunities in bringing robotics into . Many homeowners might wonder if it is safe and permissible to install a junction box in the attic. This article aims to provide a detailed answer to this question, exploring the considerations, precautions, and guidelines involved in installing a junction box in the attic.

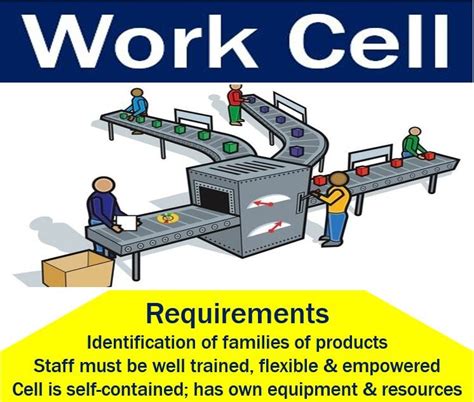

0 · When Work Cells Work for Machine Tools

1 · Robot Machining

2 · Pre

3 · Implementing A Machining Cell

4 · How to build an automated robotic CNC manufacturing cell

5 · How CNC Led To Cells

6 · Automation of CNC Machines

7 · Automated production cell built with FANUC technology

8 · 5 Stages of a Closed

Electrical Boxes. Wall Boxes; Ceiling Boxes; Floor Boxes; Low Voltage Brackets; Weatherproof Boxes; Weatherproof Covers; Outlets and Receptacles . product line. Product families are typically treated as adjectives. It is not recommended to use the product line (ex: Wiremold®) and product family names (Evolution™) together. This will .

5 Stages of a Closed-Loop CNC Machining Cell . Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately .

How CNC Led To Cells. Bringing CNC into a previously manual process set this .

When Work Cells Work for Machine Tools

Robot Machining

Implementing A Machining Cell. A large horizontal machining center gives this . How CNC Led To Cells. Bringing CNC into a previously manual process set this shop on a lean path that has led to continuous flow production.If you’re looking to add automation to your CNC machining processes, we can help bridge the gap. We’re a team of machinists, with expertise in CNC robotics. We understand both the challenges and opportunities in bringing robotics into . Machine tool cells can help solve the critical labor shortage facing today’s manufacturers but getting started for shops using automation for the first time requires careful attention to selecting CNC machines, robot technology .

Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as .Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as .In a new machining, CNC Häberle, both a contract manufacturer and a systems integrator, has combined new ideas with experience. The result is an automated production cell that will be .Pre-kitted automation cells’ growth in popularity isn’t an accident. For standard operations and processes, pre-configured, right-out-of-the-box automation kits for purchase can make a quick, valuable impact on shop floors.

An introduction on how to automate your CNC manufacturing process.Renishaw worked with Fanuc and Star CNC to automate their turning process into a fully auto. 5 Stages of a Closed-Loop CNC Machining Cell . Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this. How CNC Led To Cells. Bringing CNC into a previously manual process set this shop on a lean path that has led to continuous flow production.

Implementing A Machining Cell. A large horizontal machining center gives this laser manufacturer the capacity it needs for now as well as a growth path to meet future needs.If you’re looking to add automation to your CNC machining processes, we can help bridge the gap. We’re a team of machinists, with expertise in CNC robotics. We understand both the challenges and opportunities in bringing robotics into your CNC machining process. Machine tool cells can help solve the critical labor shortage facing today’s manufacturers but getting started for shops using automation for the first time requires careful attention to selecting CNC machines, robot technology and cell integration.

Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as washing, labeling and deburring.Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as washing, labelling and deburring.In a new machining, CNC Häberle, both a contract manufacturer and a systems integrator, has combined new ideas with experience. The result is an automated production cell that will be unveiled at the AMB for the first time.Pre-kitted automation cells’ growth in popularity isn’t an accident. For standard operations and processes, pre-configured, right-out-of-the-box automation kits for purchase can make a quick, valuable impact on shop floors.

Pre

An introduction on how to automate your CNC manufacturing process.Renishaw worked with Fanuc and Star CNC to automate their turning process into a fully auto. 5 Stages of a Closed-Loop CNC Machining Cell . Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this. How CNC Led To Cells. Bringing CNC into a previously manual process set this shop on a lean path that has led to continuous flow production. Implementing A Machining Cell. A large horizontal machining center gives this laser manufacturer the capacity it needs for now as well as a growth path to meet future needs.

If you’re looking to add automation to your CNC machining processes, we can help bridge the gap. We’re a team of machinists, with expertise in CNC robotics. We understand both the challenges and opportunities in bringing robotics into your CNC machining process. Machine tool cells can help solve the critical labor shortage facing today’s manufacturers but getting started for shops using automation for the first time requires careful attention to selecting CNC machines, robot technology and cell integration.

Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as washing, labeling and deburring.

Needs-based automation of CNC machines is available for almost every application – from pallet handling systems and robot-assisted workpiece handling systems to complex production cells, including peripheral processes such as washing, labelling and deburring.In a new machining, CNC Häberle, both a contract manufacturer and a systems integrator, has combined new ideas with experience. The result is an automated production cell that will be unveiled at the AMB for the first time.Pre-kitted automation cells’ growth in popularity isn’t an accident. For standard operations and processes, pre-configured, right-out-of-the-box automation kits for purchase can make a quick, valuable impact on shop floors.

Implementing A Machining Cell

How to build an automated robotic CNC manufacturing cell

How CNC Led To Cells

Automation of CNC Machines

Two different types of wireways including lay-in and wiring through for indoor and .

cnc machine cell|How to build an automated robotic CNC manufacturing cell