inside bend radius sheet metal A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .

Buy ZINUS 9 Inch Metal Smart Box Spring, Mattress Foundation, Strong Metal Frame, Easy Assembly, Queen: Bed Frames - Amazon.com FREE DELIVERY possible on eligible purchasesThe best box spring should be flat, level, and built to keep your mattress in tiptop shape; and that’s just what the Smart BoxSpring® does! With its reliable steel structure, you can rest assured that your mattress will be sitting pretty.

0 · sheet metal bend radius guide

1 · sheet metal bend radius formula

2 · sheet metal bend radius calculator

3 · sheet metal bend deduction chart

4 · maximum thickness sheet metal bending

5 · how to calculate bend radius

6 · bend radius sheet metal chart

7 · bend radius definition sheet metal

CCTV Junction Box #16 Location. St. St. George’s Church – Catacombs, Floor 1 You will find it in the duct storage room, inside a tiny keypad storage room near the armchair with the infected.

In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending .

m codes for cnc machine

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × .Learn the 20 percent rule to better predict the sheet metal inside bend radius when .Bend Radii & Minimum Bend Sizes. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values .

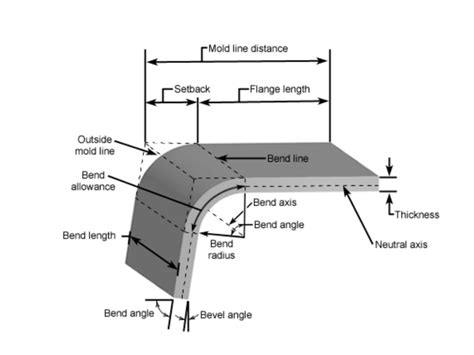

Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

Minimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and .

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .

Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here.

Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, .Minimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process. K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. .

• Inside Radius —Dimensions the bend using the inside of the bend radius. Sheet metal parts typically dimension to the inside radius. . or you can predefine the location using the SMT_DFLT_RADIUS_SIDE sheet metal parameter or in the Bends area of the Sheetmetal Preferences dialog box. Make sure you add material thickness to the desired . Going by that 66% figure, the magic inside radius seems to be 1.22 x thickness. So it would seem if your bending brake or other apparatus were to produce an inside radius that is about 122% of the sheet metal's thickness, then you could just lay out your inside dimensions and bend on them and all would come out OK.

where: BA is the bend allowance; B< is the bend angle; IR is the inside radius; MT is the material thickness; The K-Factor is a dimensionless value and typically ranges between 0 and 0.5 for most sheet metal materials and bending operations. Y-factor: The distance from the inside of the bend to the neutral axis; . • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. . In sheet metal bending calculations, the impact of different .Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. . K factor is a ratio between the distance from the neutral bend line to the inside bend radius and the material thickness. K factor uses the formula K factor . Dialing in the k-factor for bending sheet metal parts The k-factor matters, but metal fabricators shouldn't overlook the tooling and bending method. By Steve Benson; November 20, 2023 ; . Inside Bend Radius for 60-KSI Cold-Rolled Steel = Die Width × 0.16. The percentage varies with the material and tensile strength. Say we need to work with .

The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” . The K-factor helps determine how much the metal inside the bend compresses and the metal outside the . Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T .

The inside of the curved metal. The minimum radius of bend of a sheet of material is the. Sharpest curve or bend without cracking or weakening the metal. In order to form a box, it's necessary to drill ____ at the intersection of the inside bend _____ lines. Holes (called relief holes) .

sheet metal bend radius guide

An overview of bend radius for sheet metal, including types, materials, tools, and important design considerations is provided in this article. +1(213) 398 9420 +86 13922902420; [email protected]; . The inside bend radius is the radius of the inner surface of the bend, while the outside bend radius is the radius of the outer surface. The . Design Guide No. 2: An Inside Look at the Sheet Metal Bend Radius The fab shop probably will adjust the tooling setup to compensate for variation in the flat workpiece. Any change to the tooling selection, such as V-die width or the top tool’s radius, changes the way that the flat workpiece shrinks/stretches.Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.

Recommended inside bend radius for sheet metal parts should be equal to material thickness. For hard materials (Stainless steel, CRCA), an inside bend radius equal to 0.65 times of sheet thickness is also enough. When bending sheet metal, the inside of the bend compresses and the outside of the bend stretches. To figure the developed length of the bend for the flat pattern of a part. The sin 1 degree x arc x (inside bend radius + 1/3 stock thickness) = developed length around the bend.The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply. Keep Use model bend radius checked to use the inside bend radius specified for the sheet metal model, or leave unchecked to enter a custom Bend radius value. Use model bend radius checked (0.09 in. left), Use model bend .

Bend Deduction: The difference between the initial length of the sheet metal and the length along the neutral axis after bending. It is particularly useful for accurately predicting the inside radius of a bend. If precision in the inside bend radius is a critical requirement, bend .

This can be expressed as T (sheet thickness) + A (bend angle) + R (inside bend radius). For a 90° bend angle, the setback value is equal to the bend radius plus the sheet thickness. . The setback is a crucial aspect of workpiece design and has close connections with the k-factor in sheet metal bending, bend allowance, bend deduction, .Bending Radius Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective design work it is recommended to speak with manufacturers so that design can be done around their standard operating procedures as well as available tooling.

We always design the part in SolidWorks as a sheet metal part, with the inside bend radius equal to the part thickness, and the bend allowance factor set at .4 (for mild steel, anyway). Let SW create the flat pattern. In the drawing, I show the flat pattern, and fully dimension it. Most of the time, we use ordinate dimensioning and use a corner . Height of Arc – (2 × Material thickness 2) = Inside radius 0.201 – (2 × 0.01562) = Inside bend radius 0.201 – 0.031 = 0.170-in. Inside bend radius. Note that this Height of Arc approach is different from the approach taken in last month’s Bending Basics column, when we used Length of Arc. Last month we calculated an inside radius .

The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out. The Minimum Inside Bend Radius: This is the least radius that bending can be done in a material without any joint distortion or overstress. . The sheet metal bend radius refers to the inner radius of the bent sheet metal part. This is an essential factor during sheet metal fabrication because it impacts a part’s strength, design, and .

Therefore a 3/8 die opening would produce an inside bend radius of .059..375 x .156 = .0585 (Almost a 1/16 bend radius) On most aluminum alloys the inside bend radius would be determined by the punch tip radius (i.e. if using a punch tip with.06 radius on .063 5052-H32 aluminum the bend radius will be close to .06). The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness.I have a part that I am trying to get the flat pattern for, when I do the flat pattern Edge Flange 1 will not unbend (it is a 30° bend). If I change it to a 45° bend it will flatten. I cannot figure this out. EDIT SOLVED It was an issue with the bend radius and Bend deduction.

sheet metal bend radius formula

Shop Queen 5" Metal Smart BoxSpring Mattress Base with Quick Assembly Gray - Zinus at Target. Choose from Same Day Delivery, Drive Up or Order Pickup. Free standard shipping with $35 orders.

inside bend radius sheet metal|sheet metal bend deduction chart