5 axis cnc machine definition At the heart of 5-axis CNC milling lies the ability to achieve simultaneous motion along five axes: X, Y, Z, and two rotational axes, typically A and B. The A axis rotates around the X-axis, while the B axis rotates around the Y-axis. This combination of movement allows the . See more Corrosion-resistant stainless steel cleans easily, is nearly indestructible, and is highly animal-resistant ; Once un-stacked, each container makes its own elegant metal bowl - great for serving ; Use For: Travel, camping, picnicking, work & campus. Prevents food from being crushed during transport. Lightweight 18/8 Stainless Steel SUS304. BPA .

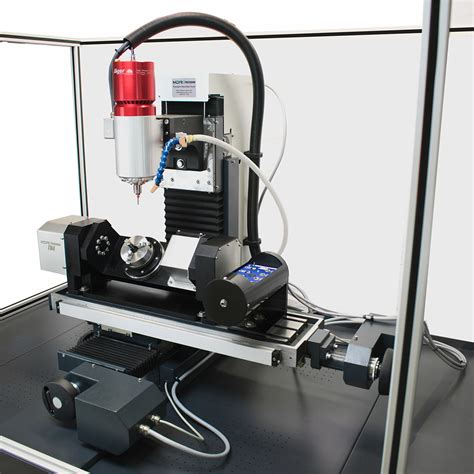

0 · small 5 axis cnc milling machine

1 · haas 5 axis cnc machine for sale

2 · benefits of 5 axis machining

3 · 5 axis machining explained

4 · 5 axis cnc milling machine for sale

5 · 5 axis cnc machine specifications

6 · 5 axis cnc machine diagram

7 · 5 axis cnc explained

Stainless steel construction allows cooking in flame or on coals, as well as with a variety of camp stoves. The internal pan is good for steaming veggies or double boiling, also heating/cooking two separate items at once, (or it can serve as your plate/bowl).

Explore the 5-axis CNC machining in this comprehensive guide. Learn how 5-axis machining enhances precision and complexity in manufacturing. See moreRecognizing the need for more versatile solutions, the industry progressed to 4-axis machining, which introduced an additional rotational . See more

5-axis machining is an advanced manufacturing technique that has revolutionized the world of CNC (Computer Numerical Control) machining. Unlike traditional 3 . See more

Enhanced Precision and Accuracy: By approaching the workpiece from different angles, 5-axis machining ensures better tool engagement and minimizes cutting vibration, resulting in higher precision and accuracy. With shorter cutting tools, there is little to no . See moreAt the heart of 5-axis CNC milling lies the ability to achieve simultaneous motion along five axes: X, Y, Z, and two rotational axes, typically A and B. The A axis rotates around the X-axis, while the B axis rotates around the Y-axis. This combination of movement allows the . See more

5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move . What Is 5-Axis CNC Machining? This procedure involves the movement of cutting tools across five axes simultaneously. 5-axis CNC machines offer three linear axes working .

small 5 axis cnc milling machine

5-axis machining represents a sophisticated CNC technology that enables simultaneous movement of cutting tools or workpieces along five distinct axes. This advanced .

What Is A 5-Axis CNC Machine? A 5-axis CNC machine moves in five different directions: X, Y, Z simultaneously with A and B. X, Y, and Z are linear axes, while A and B are rotational axes. This type of CNC machine allows an operator to . Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it .

We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the .

5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and .

haas 5 axis cnc machine for sale

5-axis CNC machining is a precise and efficient manufacturing process that can produce complex shapes and fine features through independent control of five axes.

Five axis CNC machining refers to the ability of the CNC machine to perform movement about five different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis, X. Y and . A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move across the X, Y, Z linear axes, as well as rotate on the A and B axes to approach the workpiece from any direction. What Is 5-Axis CNC Machining? This procedure involves the movement of cutting tools across five axes simultaneously. 5-axis CNC machines offer three linear axes working simultaneously with two rotational axes to achieve intricate parts. This typically adds more tilt to the worktable or tool spindly, allowing for increased rotation and movement.

5-axis machining represents a sophisticated CNC technology that enables simultaneous movement of cutting tools or workpieces along five distinct axes. This advanced capability allows the cutting tool to approach the workpiece from virtually any angle, facilitating the production of highly complex and precise components.What Is A 5-Axis CNC Machine? A 5-axis CNC machine moves in five different directions: X, Y, Z simultaneously with A and B. X, Y, and Z are linear axes, while A and B are rotational axes. This type of CNC machine allows an operator to work from all different directions without having to manually reposition the part or the machine tools.

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle . We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications.5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts. 5-axis CNC machining is a precise and efficient manufacturing process that can produce complex shapes and fine features through independent control of five axes.

benefits of 5 axis machining

Five axis CNC machining refers to the ability of the CNC machine to perform movement about five different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis, X. Y and Z, with the Z axis being parallel to . A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move across the X, Y, Z linear axes, as well as rotate on the A and B axes to approach the workpiece from any direction. What Is 5-Axis CNC Machining? This procedure involves the movement of cutting tools across five axes simultaneously. 5-axis CNC machines offer three linear axes working simultaneously with two rotational axes to achieve intricate parts. This typically adds more tilt to the worktable or tool spindly, allowing for increased rotation and movement. 5-axis machining represents a sophisticated CNC technology that enables simultaneous movement of cutting tools or workpieces along five distinct axes. This advanced capability allows the cutting tool to approach the workpiece from virtually any angle, facilitating the production of highly complex and precise components.What Is A 5-Axis CNC Machine? A 5-axis CNC machine moves in five different directions: X, Y, Z simultaneously with A and B. X, Y, and Z are linear axes, while A and B are rotational axes. This type of CNC machine allows an operator to work from all different directions without having to manually reposition the part or the machine tools.

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle . We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications.5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts. 5-axis CNC machining is a precise and efficient manufacturing process that can produce complex shapes and fine features through independent control of five axes.

yukon steel cabinet

yugioh metal raiders booster box 1st edition cheap

I want to know the locations of the gigantic metal boxes like the ones at woodland tower, wasteland tower, and the akkala citadel ruins so I can use them to kill lynels. Edit: So apparently there’s a website that catalogs everything in botw, and I mean everything. There's quite a number of them surrounding the wasteland tower.

5 axis cnc machine definition|5 axis cnc machine specifications