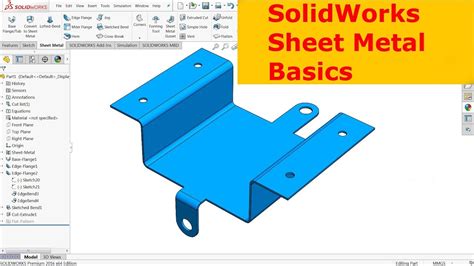

covert to sheet metal Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met. Truck tool boxes are typically constructed of four different materials: aluminum, steel, stainless steel, and heavy-duty plastic. Let's quickly walk through the pros and cons of each one. Most truck tool boxes are made from aluminum and feature a diamond plate design on the surface.

0 · solid work to sheet metal conversion

1 · solid work to sheet metal

2 · solid to sheet metal worksheets

3 · convert solid part to sheet metal

4 · convert solid metal to sheet metal

Enswells: the cold steel plates that I mentioned above that help reduce swelling and blood flow. Bottled water: used to help wipe down the fighters during rounds, for cleaning out and dampening their mouths, a little drinking but not much!

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met.

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create .

Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or . Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. .Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to . “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part .

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. The SOLIDWORKS Convert to Sheet Metal command is an efficient way to create Sheet Metal geometry without having to be proficient in using Sheet Metal features. Converting a regular solid or surface body to a sheet metal model that can be flattened (unfolded), can help facilitate the manufacturing of the part.

Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met.This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table.

Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the partUse the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to Sheet Metal tool, you can keep the solid body to use with multiple Convert to Sheet Metal features. “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part modeling features such as extrudes and lofts.

solid work to sheet metal conversion

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. The SOLIDWORKS Convert to Sheet Metal command is an efficient way to create Sheet Metal geometry without having to be proficient in using Sheet Metal features. Converting a regular solid or surface body to a sheet metal model that can be flattened (unfolded), can help facilitate the manufacturing of the part.

install metal electrical box ts bracket

Learn about this tip for those who use #SOLIDWORKS sheet metal. You probably, normally, come across a sketch and pull-edge type of flange to create sheet met.This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.

How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table. Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the part

Use the Convert To Sheet Metal PropertyManager to convert a solid or surface body to a sheet metal part. The solid body can be an imported sheet metal part. When using the Convert to Sheet Metal tool, you can keep the solid body to use with multiple Convert to Sheet Metal features.

solid work to sheet metal

solid to sheet metal worksheets

The following things come in your iPhone 12 box. Obviously we're not counting the documentation and SIM removal tool here.

covert to sheet metal|convert solid metal to sheet metal