a straight fin fabricated from 2024 aluminum alloy A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, .

Here are three CNC machines to discuss as you evaluate CNC machining vs Manual machining. CNC mill machine. CNC milling is a universal method used for complex parts manufacturing. It utilizes a rotating cylindrical tool to remove material from a solid block and realize custom-designed parts.

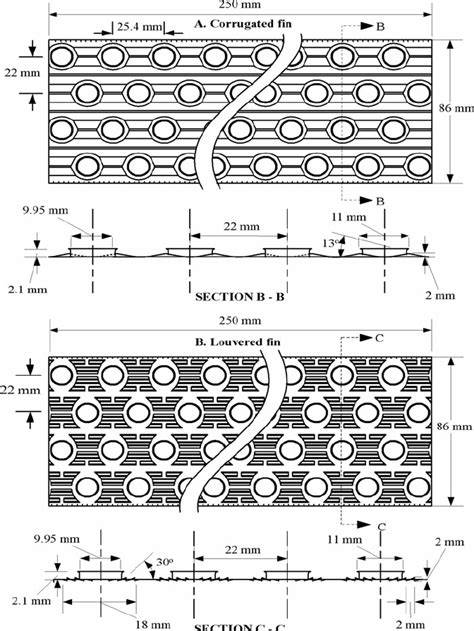

0 · straight fin diagram

1 · aluminum straight fin diagram

$26.99

A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid .Solution: Consider the diagram showing straight fins of rectangular, triangular, .A straight fin fabricated from 2024 aluminum alloy (k=185 W/m⋅K) has a base . The question involves comparing the fin heat rate, efficiency, and volume among rectangular, triangular, and parabolic straight fins made from 2024 aluminum alloy, using their .

Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal . A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, . A straight, rectangular fin fabricated from aluminum alloy (2024-T6) is 3.5 mm thick and protrudes 2.5 cm from a wall. The base is at 42°C and the ambient air temperature is . A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is .

A straight fin fabricated from 2024 aluminum alloy $(k=185 \mathrm{~W} / \mathrm{m}-\mathrm{K})$ has a base thickness of $t=3 \mathrm{~mm}$ and a length of $L=15 . A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing .

straight fin diagram

A straight fin fabricated from 2024 aluminum alloy (k=185 W/m⋅K) has a base thickness of t=3 mm and a length of L=11 mm. Its base temperature is Tb=100∘C, and it is exposed to a fluid for which T∞=20∘C and h=50 W/m2⋅K.A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid for which T? = 20 C and h = 50 W/m2?K. The question involves comparing the fin heat rate, efficiency, and volume among rectangular, triangular, and parabolic straight fins made from 2024 aluminum alloy, using their dimensions, thermal properties, and given environmental conditions. Explanation:Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal conductivity, and t is the base thickness. Substitut .

A straight fin fabricated from 2024 Aluminum alloy (k=185 W/mK) has a base thickness of t=3 mm and a length of L=15 mm. Its base temperature is Tb=100oC, and it is exposed to a fluid for which T[infinity] =20oC and h=50 W/m2K. A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, and it is exposed to a fluid with T[infinity] = 20°C and a convective heat transfer coefficient of .

A straight, rectangular fin fabricated from aluminum alloy (2024-T6) is 3.5 mm thick and protrudes 2.5 cm from a wall. The base is at 42°C and the ambient air temperature is 30°C. The heat transfer coefficient may be taken as 11 W/m^2K. A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is exposed to a fluid for which T∞ = 20°C and h = 50 W/m2 ∙ K.A straight fin fabricated from 2024 aluminum alloy $(k=185 \mathrm{~W} / \mathrm{m}-\mathrm{K})$ has a base thickness of $t=3 \mathrm{~mm}$ and a length of $L=15 \mathrm{~mm}$. Its base temperature is $T_{b}=100^{\circ} \mathrm{C}$, and it is exposed to a fluid for which $T_{w}=20^{\circ} \mathrm{C}$ and $h=50 \mathrm{~W} / \mathrm{m}^{2} \cdot .

A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing conditions and a fin of unit width, compare the fin heat rate, efficiency, and volume of a .A straight fin fabricated from 2024 aluminum alloy (k=185 W/m⋅K) has a base thickness of t=3 mm and a length of L=11 mm. Its base temperature is Tb=100∘C, and it is exposed to a fluid for which T∞=20∘C and h=50 W/m2⋅K.A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid for which T? = 20 C and h = 50 W/m2?K.

The question involves comparing the fin heat rate, efficiency, and volume among rectangular, triangular, and parabolic straight fins made from 2024 aluminum alloy, using their dimensions, thermal properties, and given environmental conditions. Explanation:Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal conductivity, and t is the base thickness. Substitut .

aluminum straight fin diagram

A straight fin fabricated from 2024 Aluminum alloy (k=185 W/mK) has a base thickness of t=3 mm and a length of L=15 mm. Its base temperature is Tb=100oC, and it is exposed to a fluid for which T[infinity] =20oC and h=50 W/m2K.

A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, and it is exposed to a fluid with T[infinity] = 20°C and a convective heat transfer coefficient of .

A straight, rectangular fin fabricated from aluminum alloy (2024-T6) is 3.5 mm thick and protrudes 2.5 cm from a wall. The base is at 42°C and the ambient air temperature is 30°C. The heat transfer coefficient may be taken as 11 W/m^2K. A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is exposed to a fluid for which T∞ = 20°C and h = 50 W/m2 ∙ K.A straight fin fabricated from 2024 aluminum alloy $(k=185 \mathrm{~W} / \mathrm{m}-\mathrm{K})$ has a base thickness of $t=3 \mathrm{~mm}$ and a length of $L=15 \mathrm{~mm}$. Its base temperature is $T_{b}=100^{\circ} \mathrm{C}$, and it is exposed to a fluid for which $T_{w}=20^{\circ} \mathrm{C}$ and $h=50 \mathrm{~W} / \mathrm{m}^{2} \cdot . A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing conditions and a fin of unit width, compare the fin heat rate, efficiency, and volume of a .

The only time you’re allowed to stop in a yellow box is when you are turning right. You must still make sure your exit road is clear, but you may have to wait for a gap in oncoming traffic before actually turning.

a straight fin fabricated from 2024 aluminum alloy|straight fin diagram