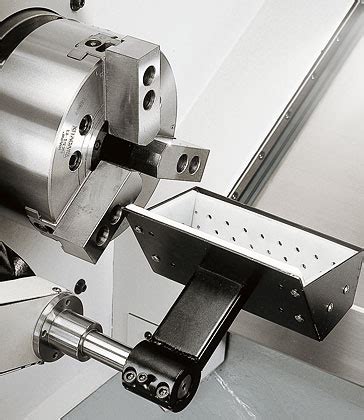

cnc lathe parts catcher In this video Orville walks us through adjusting the Lathe Parts Catcher to properly catch your part and also looks at the three M-Codes you use to program t. Phone: 908-276-5500 Fax: 908-276-6808 westfieldsheetmetal.com. Sales Contact. Gregg Wheatley . Comptroller. Email: [email protected] Sales: 908-276-5500

0 · parts catcher tray

1 · parts catcher for sale

2 · orville lathe parts catcher

3 · lathe parts catcher m code

4 · lathe parts catcher adjustment

5 · lathe parts catcher

6 · haas parts catcher

7 · automatic parts catcher

Both box springs and foundations offer support for a new mattress—but which is best for your bed? Our box spring vs. foundation comparison is here to help.

Our simple, two-stage parts catcher is easy to adjust, and will catch parts at the main or sub-spindle, without ever having to open the door. Our two-stage automatic parts catcher moves .This procedure shows you how to install the Single Action Parts Catcher on Angled .The CL Parts Catcher rotates into position to catch the finished part as it is cut off, .This procedure shows you how to install the Single Action Parts Catcher on Angled Door ST-20/25/30/35 and DS-30 machines.

In this video Orville walks us through adjusting the Lathe Parts Catcher to properly catch your part and also looks at the three M-Codes you use to program t.

The CL Parts Catcher rotates into position to catch the finished part as it is cut off, and directs it into a bin located on the front of the machine. It is easily adjusted to accommodate different .

The Royal Rota-Rack® adapts to any CNC lathe that is equipped with a part catcher: Turntable can rotate either clockwise or counterclockwise, and can be positioned to either the left side or .

We provide CNC lathe parts catchers for catching and collecting finished parts as they are machined and ejected from the lathe. See more on our website!Hugard Inc. uses a custom claw as a parts collector to catch precision turned parts as they’re parted off by a CNC lathe. Because the parts are both extremely complex and subject to a constant stream of corrosive cutting fluid, they’re .

The parts catcher on my Conquest T42 behaves the same way - alarms out if you try to retract it in MDI. Pressing reset button works fine to retract it. I believe the way the ladder . Does anyone know of a decent aftermarket lathe parts catcher setup? I am looking at a project that would be perfect for a pull and catch system and I don't have a catcher on my .

In order for a CNC lathe parts catcher to work, it needs some kind of transmission link to convert the rotary motion of the motors into the translational motion of the axes. In this article, we will look at the common types of .

Our simple, two-stage parts catcher is easy to adjust, and will catch parts at the main or sub-spindle, without ever having to open the door. Our two-stage automatic parts catcher moves completely out of the primary work envelope during machining, and quickly moves into place when commanded during the part-off operation.This procedure shows you how to install the Single Action Parts Catcher on Angled Door ST-20/25/30/35 and DS-30 machines. In this video Orville walks us through adjusting the Lathe Parts Catcher to properly catch your part and also looks at the three M-Codes you use to program t.

The CL Parts Catcher rotates into position to catch the finished part as it is cut off, and directs it into a bin located on the front of the machine. It is easily adjusted to accommodate different part-off locations, and finished parts can be retrieved without opening the door.The Royal Rota-Rack® adapts to any CNC lathe that is equipped with a part catcher: Turntable can rotate either clockwise or counterclockwise, and can be positioned to either the left side or right side of the lathe.We provide CNC lathe parts catchers for catching and collecting finished parts as they are machined and ejected from the lathe. See more on our website!

Hugard Inc. uses a custom claw as a parts collector to catch precision turned parts as they’re parted off by a CNC lathe. Because the parts are both extremely complex and subject to a constant stream of corrosive cutting fluid, they’re unsuitable for CNC Milling and . The parts catcher on my Conquest T42 behaves the same way - alarms out if you try to retract it in MDI. Pressing reset button works fine to retract it. I believe the way the ladder is written, you can't MDI anything while the parts catcher is extended. Does anyone know of a decent aftermarket lathe parts catcher setup? I am looking at a project that would be perfect for a pull and catch system and I don't have a catcher on my old Takisawa. In order for a CNC lathe parts catcher to work, it needs some kind of transmission link to convert the rotary motion of the motors into the translational motion of the axes. In this article, we will look at the common types of transfers and describe their advantages and disadvantages, as well as their areas of application.

Our simple, two-stage parts catcher is easy to adjust, and will catch parts at the main or sub-spindle, without ever having to open the door. Our two-stage automatic parts catcher moves completely out of the primary work envelope during machining, and quickly moves into place when commanded during the part-off operation.This procedure shows you how to install the Single Action Parts Catcher on Angled Door ST-20/25/30/35 and DS-30 machines. In this video Orville walks us through adjusting the Lathe Parts Catcher to properly catch your part and also looks at the three M-Codes you use to program t.The CL Parts Catcher rotates into position to catch the finished part as it is cut off, and directs it into a bin located on the front of the machine. It is easily adjusted to accommodate different part-off locations, and finished parts can be retrieved without opening the door.

The Royal Rota-Rack® adapts to any CNC lathe that is equipped with a part catcher: Turntable can rotate either clockwise or counterclockwise, and can be positioned to either the left side or right side of the lathe.We provide CNC lathe parts catchers for catching and collecting finished parts as they are machined and ejected from the lathe. See more on our website!

Hugard Inc. uses a custom claw as a parts collector to catch precision turned parts as they’re parted off by a CNC lathe. Because the parts are both extremely complex and subject to a constant stream of corrosive cutting fluid, they’re unsuitable for CNC Milling and .

The parts catcher on my Conquest T42 behaves the same way - alarms out if you try to retract it in MDI. Pressing reset button works fine to retract it. I believe the way the ladder is written, you can't MDI anything while the parts catcher is extended. Does anyone know of a decent aftermarket lathe parts catcher setup? I am looking at a project that would be perfect for a pull and catch system and I don't have a catcher on my old Takisawa.

yellow house with metal roof

20 Pack 1x1 Corner Brace with Screws - Zinc Plated Steel L Brackets for Picture Frames - Includes 20 Corner Braces and 40 1/2" x 6 Gauge Flat Head Phillips Screws

cnc lathe parts catcher|automatic parts catcher