mill finish cnc parts factory High-Quality Lustrous Satin Finish (Paint) Services. Satin Finish Service at CNCLATHING.COM is capable of delivering precise and uniform metal surfaces, focusing on performance and . Check out our wood box metal accent selection for the very best in unique or custom, handmade pieces from our boxes & bins shops.

0 · what is cnc machining

1 · surface finish for cnc machining

2 · surface finish for cnc cutting

3 · cnc machining finishes

$4.99

what is cnc machining

High-Quality Lustrous Satin Finish (Paint) Services. Satin Finish Service at CNCLATHING.COM is capable of delivering precise and uniform metal surfaces, focusing on performance and .Work with our expert engineers to select the right finishing option for your CNC machining project, including powder coating, bead blasting, painting, and surface detailing. Applying finishes and .You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish .

Aluminum finishes are crucial in enhancing the performance and aesthetics of CNC parts made from this versatile metal. Designers and manufacturers widely favor aluminum for its remarkable strength-to-weight .

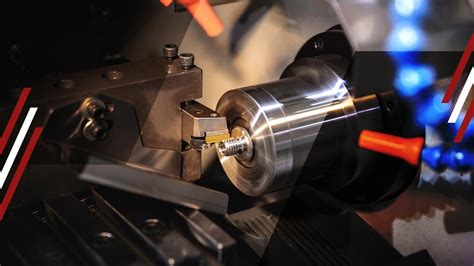

2.2 Milling Finishes. Milling is another essential machining technique that offers a wide range of finishing options. From face milling to profile milling, each approach delivers unique surface textures and characteristics. 2.3 Grinding Finishes. Grinding is renowned for its ability to achieve high precision and tight tolerances.

However, parts fabricated with CNC milling machines often have visible marks. . (0.4, 0.8, 1.6, and 3.2 µm Ra). Our state-of-the-art CNC machining factory and network of suppliers allow us to deliver quality plastic .As an ISO 9001 certified factory,Chiggo is able to provide ultra-precision CNC turning lathe parts parts, guaranteing all parts will be made according to your specification. If 2D drawings are not available, we will follow ISO 2768 standards and advise the appropriate tolerance grade for your specific project.Item Name: Custom brass milling parts; Craftsmanship: CNC milling; Finish: / Price: Real Instant Factory Price; Packing: PE. . China precision brass milling parts suppliers, factory, Electrical Stamping Die, Custom Brass Parts, Small Metal Parts, Stamping Stainless Steel Parts, Custom Heat Sink, Sheet Metal Bending Parts.

For tooling start-up costs I expect to spend maybe 0 tops Forget that number. You need a bare minimum of a vice (0), 7 tool holders (00, you forgot a drill for that tap, ER32 for application flexibility), collets (0), a pack of each of your cutters (since you will inevitably ruin a bunch learning - your 0), part stops, and so on. . Figure 00 to make a single type of .

As a leading CNC parts manufacturer, we understand the importance of achieving a flawless mill finish. In this blog post, we will explore the significance of mill finish, techniques to achieve excellence, and the benefits it brings to the overall manufacturing process. The Importance of Mill Finish. Mill finish refers to the surface finish of a .Metal Parts CNC Precision Machining Factory. SKY-CNC is a metal parts CNC precision machining manufacturer. We have 20+ years of industrial design and 10+ years of CNC machining experience, so we have a better understanding of products and OEM/ODM parts, to ensure your ideas and projects are brought to market quickly and on-time.

2.1 Mill Finish. Explain what mill finish entails, its characteristics, and common uses across different industries. Discuss the pros and cons of this type of surface finish and when it is the preferred choice. 2.2 Brushed Finish. Detail the process of creating a brushed finish on steel surfaces, highlighting its unique texture and visual appeal. Buffing for Mirror Finish: Switch to a finer buffing wheel and apply a small amount of finer polishing compound to achieve a higher level of shine. Continue buffing in the same circular motion, gradually increasing the pressure to bring out the mirror-like finish. Final Finish:As an ISO 9001 certified factory,Chiggo is able to provide ultra-precision CNC turning lathe parts parts, guaranteing all parts will be made according to your specification. If 2D drawings are not available, we will follow ISO 2768 standards and advise the appropriate tolerance grade for your specific project.If you're looking for mill finish cnc parts then there is nothing as good as Prodigious Mill Finish CNC Machined Parts . This site has an inventory that comprises of thousands of new and used mill finish cnc parts . These are all offered at great prices, so check them out! mill finish cnc parts

Characteristics of a Mill Finish: Although a mill finish is a recognized standard, there are usually slight differences between the different metals as well material production processes. The most common mill finish metal is aluminum. At this state, mill finish aluminum will usually have a very thin oxide film, which is common for both extruded . Optimize CNC parts with 10 aluminum finishes. Enhance corrosion resistance, durability, and visual appeal for custom components. . Surface finish in CNC machining is defined as the texture and smoothness of machined exterior parts. . Best CNC Machined Parts Manufacturer and Factory in China. Offer Fast and Cost-Effective One-Stop CNC .

surface finish for cnc machining

CNC milling is a reliable and standard method for fabricating parts in mass volume, with each part having the same level of quality and finish. Moreover, CNC mills, especially 3-axis milling machines, are often easy to .Chiggo offers on-demand CNC milling services with our 3-, 4-, and 5-axis CNC mills. Get your custom milled parts and prototypes at competitive prices. On-Demand Manufacturing for Custom Parts. . with direct factory connections and clear, transparent communication, ensure that every order, no matter its complexity or size, is delivered with .Making your own mill finish cnc parts tool. Mill Finish CNC Parts manufacturer. Making your own mill finish cnc parts tool is a simple job that can be done by anyone. We have provided all the necessary information to build a mill finish cnc part tool, so you don't need to .Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM

Once satisfied with the finish, carefully pack the polished CNC parts to prevent any damage during storage or transportation. By following these steps and exercising caution, you can achieve a polished finish on aluminum CNC parts that enhances their aesthetics while maintaining the precision and functionality of the machined components.

Yuhuan Hongqian Machinery Co., Ltd was established in 2016 and is located in Damixi, Longxi, Yuhuan, Zhejiang Province, China. We specialize in the manufacturing of precision machined Custom cnc machine parts and cnc turning parts using a variety of materials including carbon steel, stainless steel, aluminum, and brass.Our advantage is produce nonstandard metal parts .Hot Wire CNC foam Cutting is similar to wire EDM cutting and usually creates a nice and smooth surface finish. We cut EPS, XPS and EPP foam with our CNC hot wire foam cutters, creating 2D projects. We create signs, logo, stage letters, props, backdrops, billboards, exhibits and displays for movies, theatres, museums, trade shows, sign shops .Aluminum is strong, lightweight and corrosion-resistant, making it ideal for aerospace, automotive and electronic parts. With over 12 years of experience, more than 150 sets milling machines and CNC centers,over 350 well-trained employees and ISO9001:2015 certification, our company has the expertise and knowledge to produce the highest quality machined partsBoyi CNC turned stainless steel parts has perfect finish and tight tolerances, widely used in medical, automotive, optical, mechanical industries. . complex stainless steel CNC milling parts, Boyi CNC milling service will never let you down. We have advanced 3-, 4-, 5- axis CNC milling centers to help customers’ stainless steel CNC milling .

In many industries, the best repair and manufacturing experience comes with using OEM parts. Not only are these parts more reliable and durable, but they don’t require frequent replacement. These parts undergo regular testing and quality assurance procedures, which means you need a machining shop who uses only the best materials.High precision OEM CNC Milling Turning service CNC machined productsIf you have some parts with high tolerance , high surface finish requirements or strict q.

93-3745 - CT40 Mill Surface Finish Test Cut Kit; 93-3746 - CT50 Mill Surface Finish Test Cut Kit; 93-3747 - HSK63A Mill Surface Finish Test Cut Kit; Metric Test Cut Kit: 93-3788 - BT40 Mill Surface Finish Test Cut Kit Metric; 93-3787 - CT40 Mill Surface Finish Test Cut Kit Metric; 93-3790 - CT50 Mill Surface Finish Test Cut Kit Metric; 93-3789 .

Architects have put a contemporary spin on woodland homes, creating spectacular structures of glass, wood, and steel that take advantage of their beautiful settings. From a lake house in.

mill finish cnc parts factory|what is cnc machining