07600 flashing and sheet metal 1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or . Rugged storage for Williams premium socket sets, constructed for long life ; Ideal for storing socket sets, other tools and small parts ; Made from cold-rolled steel ; Made in the United States › See more product details

0 · Section 07600 Flashing and Sheet Metal

1 · SECTION 07600CP – FLASHING AND SHEET METAL

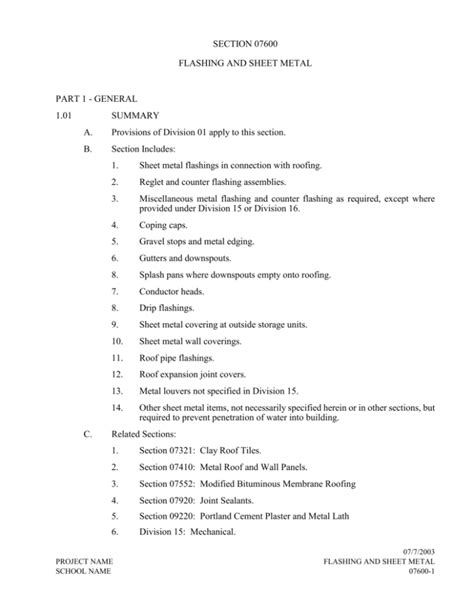

2 · SECTION 07600 FLASHING AND SHEET METAL

3 · SECTION 07600

4 · Flashing

5 · FLASHING AND SHEET METAL 07600

6 · CONSTRUCTION STANDARD SPECIFICATION SECTION

Do not get a fully metallic enclosure if you want to utilize the onboard wifi and bluetooth functions. Flirc cases degregate Wifi a significant but not unusable amount. They have a plastic bottom cover and a slot for the SD card which is the direction the antenna fires in.

1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or .

tipos de soldaduras en estructuras metalicas

07600CP - 3 of 3 Flashing & Sheet Metal Criteria & Performance Requirements D. Expansion Provisions: For exposed flashings subjected to thermal cycles, provide movement .The principal items of sheet metal work shall include sheet metal flashings, collars, pitch pockets, metal siding, equipment platforms, equipment supports at all roof penetrations, metal wall .1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or .

Section 07600 Flashing and Sheet Metal

Coordinate metal flashing and trim work with the installation of roofing, waterproofing, drains, piping, reglets, framing at openings, curbs, parapets and other adjoining work. Comply with .A. Regulatory Requirements: Flashing and sheet metal shall comply with requirements of SMACNA latest standards. B. Coordinate application of flashings with application of

technical proponents, including their organization. designation and telephone number, is on the Internet.. Recommended changes to a UFGS should be submitted asI. Adhesives: Type recommended by flashing sheet manufacturer for waterproof/weather-resistant seaming and adhesive application of flashing sheet. J. Reglets: Metal or plastic units of type .07600 Flashing - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document provides specifications for flashing and sheet metal work. It covers materials, fabrication, and installation.1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or as specified. 3. Space expansion and contraction joints for copper, stainless steel, and copper clad stainless steel at intervals not exceeding 7200 mm (24 feet). 4.

SECTION 07600CP – FLASHING AND SHEET METAL

SECTION 07600 FLASHING AND SHEET METAL

flashing, sheet metal, and trim work similar in material, design, and extent to that indicated for project that have resulted in construction with a record of successful in-service performance.

07600CP - 3 of 3 Flashing & Sheet Metal Criteria & Performance Requirements D. Expansion Provisions: For exposed flashings subjected to thermal cycles, provide movement joints at maximum of 20 feet (6 m) with no joints allowed within 24 inches (610-mm) of corner or intersection. Reinforce all metal flashing corners.

The principal items of sheet metal work shall include sheet metal flashings, collars, pitch pockets, metal siding, equipment platforms, equipment supports at all roof penetrations, metal wall flashing and expansion joints, and miscellaneous sheet metal

1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or as specified.Coordinate metal flashing and trim work with the installation of roofing, waterproofing, drains, piping, reglets, framing at openings, curbs, parapets and other adjoining work. Comply with "Architectural Sheet Metal Manual" of the Sheet Metal and Air Conditioning Contractor's National Association (SMACNA) unless specifically shown otherwise.A. Regulatory Requirements: Flashing and sheet metal shall comply with requirements of SMACNA latest standards. B. Coordinate application of flashings with application oftechnical proponents, including their organization. designation and telephone number, is on the Internet.. Recommended changes to a UFGS should be submitted as

I. Adhesives: Type recommended by flashing sheet manufacturer for waterproof/weather-resistant seaming and adhesive application of flashing sheet. J. Reglets: Metal or plastic units of type and profile indicated, compatible with flashing indicated, non-07600 Flashing - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. This document provides specifications for flashing and sheet metal work. It covers materials, fabrication, and installation.

1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or as specified. 3. Space expansion and contraction joints for copper, stainless steel, and copper clad stainless steel at intervals not exceeding 7200 mm (24 feet). 4.flashing, sheet metal, and trim work similar in material, design, and extent to that indicated for project that have resulted in construction with a record of successful in-service performance.

07600CP - 3 of 3 Flashing & Sheet Metal Criteria & Performance Requirements D. Expansion Provisions: For exposed flashings subjected to thermal cycles, provide movement joints at maximum of 20 feet (6 m) with no joints allowed within 24 inches (610-mm) of corner or intersection. Reinforce all metal flashing corners.The principal items of sheet metal work shall include sheet metal flashings, collars, pitch pockets, metal siding, equipment platforms, equipment supports at all roof penetrations, metal wall flashing and expansion joints, and miscellaneous sheet metal1. Fabricate in accordance with the Architectural Sheet Metal Manual recommendations for expansion and contraction of sheet metal work in continuous runs. 2. Space joints as shown or as specified.

Coordinate metal flashing and trim work with the installation of roofing, waterproofing, drains, piping, reglets, framing at openings, curbs, parapets and other adjoining work. Comply with "Architectural Sheet Metal Manual" of the Sheet Metal and Air Conditioning Contractor's National Association (SMACNA) unless specifically shown otherwise.

SECTION 07600

A. Regulatory Requirements: Flashing and sheet metal shall comply with requirements of SMACNA latest standards. B. Coordinate application of flashings with application oftechnical proponents, including their organization. designation and telephone number, is on the Internet.. Recommended changes to a UFGS should be submitted asI. Adhesives: Type recommended by flashing sheet manufacturer for waterproof/weather-resistant seaming and adhesive application of flashing sheet. J. Reglets: Metal or plastic units of type and profile indicated, compatible with flashing indicated, non-

Flashing

WildSmiles are designer braces that turn orthodontic correction into the ultimate braces experience. Braces are a common milestone for many kids and teens. However, traditional .

07600 flashing and sheet metal|FLASHING AND SHEET METAL 07600