how to make a sheet metal cone How To Build A Steep Cone in Sheet Metal. Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted.

Use thinner wire: Novice welders should understand that thinner wire needs to be used when MIG welding sheet metal. Thicker welding wire also means more heat which will result in you damaging the panel you are welding.

0 · truncated cone from flat sheet

1 · sheet metal transition layout

2 · sheet metal cone rolling calculation

3 · sheet metal cone formula

4 · sheet metal cone fabrication

5 · creating a cone layout

6 · cone sheet metal calculator

7 · cone layout formula

San Francisco Bay Area Architectural Sheet Metal Company Specializing in private commercial office, high-density housing, and mid to highrise construction. Recent Projects

truncated cone from flat sheet

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular.

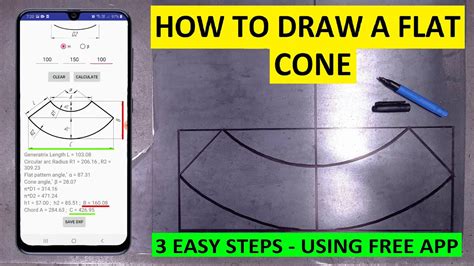

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .

Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions. Layout of a cone template for sheet metal fabrication. Stephen Marchio. 7.25K subscribers. 758. 99K views 4 years ago.

Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step . How To Build A Steep Cone in Sheet Metal. Here's the build of part of the ether cone as seen in the previous "How To Make A Sheet Metal Pattern From Scratch" video I posted.Learn the step-by-step process of making a cone from sheet metal, including cutting, bending, welding, and finishing. Asianstar CNC Machining is a professional supplier of sheet metal .Step 1: Draw Elevation View & Plan View for Full Cone Shape. Step 2: Divide Top View Circle of Cone in equal no. of Parts. Step 3: Measure Slant Height of the Cone in elevation view. Step 4: Draw Development Circle with Radius as Slant .

sheet metal transition layout

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with . Learn how to create a sheet metal cone with sketches, lofted bend, and flat pattern in SOLIDWORKS. Follow the step-by-step instructions and tips from a SOLIDWORKS technical support expert. •you need to build your cylindrical or conical shape in the sheet metal environment. I've read and understood the 6 rules of Sheet Metal. But I can't figure out how to make a cone in Sheet Metal. (I can make cones all day .

Check out this channel (MECHBUZZ) - https://www.youtube.com/channel/UCg2nh83oJkc5nrvwIaV2aVQDownload 2d drawing here - https://drive.google.com/file/d/1Lb076. Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this .Step 2: Mark and Cut the Sheet Metal . Now that you have your dimensions, it's time to mark and cut the sheet metal. Using a compass or trammel, draw a large circle with a radius equal to the slant height (L) on the sheet metal. Then, draw a smaller circle within the larger circle, with a radius equal to the top radius (R2).

#MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late.

Learn Autodesk Inventor sheet metal tutorial how to create cone object, check it out!!!Don't forget guys, if you like our videos please "Subscribe", "Like", .Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need.

Step 1: Select Full Cone Option from Application Home Screen as shown in the below image for step 1. Step 2: Enter Input data of Cone Diameter as 500 mm and Cone Height as 750 mm in the input Fields and Press Calculate Button as shown in the below image of step 2.I use this method to make cones of a specific size, I mostly use it to make templates for metal or fabric. Step 1: Draw a Profile of the Cone You Want to Make Draw a profile of the cone you want to make.

Learn how to convert a solid cone into sheet metal, and pattern a cut feature along a curve driven pattern at the flat pattern level.For more information abo.Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th.

Learn how to layout a cone in sheet metal Learn how to layout a cone and the formula, these numbers can be replaced with your dimensions. The formula for the cone is.

sheet metal cone rolling calculation

This small video shows how to make a cone in SolidWorks, using Bends feature. I hope you like this video.))Please SUBSCRIBE on my channel for more videos and. SolidWorks II Sheet Metal II Four Ways To Create Sheet Metal - ConeIn this video, I am going to explain Four difference ways to create Sheet Metal - Cone----. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Make a sheet metal cone/Cover the top of octagonal roof.My idea.Apply silicon after hitting 8 screws.Metal worksRooferhttps://www.takisawaroof.com/

Make sure you split the same segment on each polygon for the loft to generate correctly. I lofted the 2 polygons to create the cone shape. After creating the loft surface I then used the sheet metal command to convert the loft to sheet metal solid. It . and cutout , to make perfect cones. that other cone program ain't it. W. winchman Stainless. Joined Jun 19, 2003 Location Thomasville, GA. Aug 28, 2005 #13 Marv, . The patern of the cones are a half circle cut out of a 13" wide strip of sheet metal. So the question is - is there a source of a simple machine that I have missed, or even .Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry. This app helps to Fabrication Engineer, Fabrication Fitter . In this video, I show how to make a reducer from sheet metal

Creating a cone in sheet metal, which can be flattened for a pattern, is something you'll need to know a trick or two to do. Why? Well - Fusion 360's math as.

How do you make a cone shape? How do you make a funnel with sheet metal?How do you make a flat material cone?How do you cut a cone shape out of sheet metal?h. Video showing the processes involved in producing a steel cone. It a job that requires a little skill and a lot of patience! Video showing the processes involved in producing a steel cone. It a . But I can't figure out how to make a cone in Sheet Metal. (I can make cones all day in Model, but they won't flatten/unwrap) I've actually managed tosuccessfully accomplish all this with a cylindrical shape, having created the shape with the flange tool.Learn how to form a cone by cone bending on Revolution Machine Tools R-SMART 6-709 4 Roll Plate Roll.Presented by Atakan NerminerTo learn more visit http://w.

Check out my Fabrication & Engineering School / Community https://www.skool.com/fabricademy/aboutWelcome to my video on how to make tapered exhaust cones. I.

sheet metal cone formula

cnc steel machining parts supplier

Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a filler rod to create a continuous weld across the entire seam of the pieces being joined.

how to make a sheet metal cone|cone sheet metal calculator