diy bend sheet metal At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). What does 10 spaces, 20 circuits mean on a circuit breaker panel? Ten circuits on each incoming hot. s x 10 = 2o circuits. It means the panel can use the mini or tandem breakers where you get two breakers in one slot. The tandems are the yellow marked one. A normal one is seen below them.

0 · simple diy metal bender

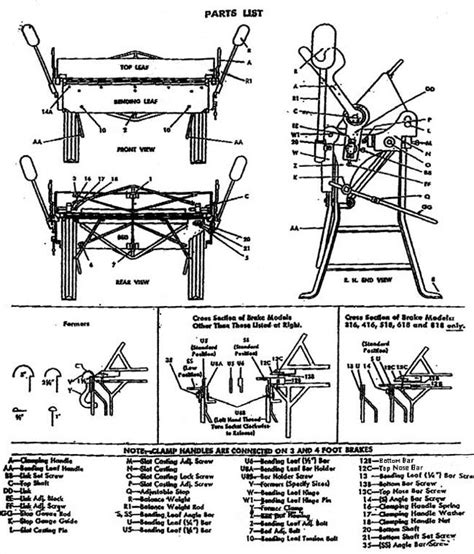

1 · sheet metal brake instructions

2 · sheet metal bending brake

3 · how to bend galvanized steel

4 · homemade sheet metal brake

5 · homemade metal bender

6 · home made sheet metal bender

7 · bending 16 gauge sheet metal

For sheet-metal parts, 5052 is preferred, as the metal can bend to a tighter radius than 6061 without cracking. For CNC machined parts, panels and enclosures, 6061 Aluminum is ideal, because the material is softer and is easily milled.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

simple diy metal bender

sheet metal brake instructions

At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and.Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until .A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal .

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and.Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent.

A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal brakes can be expensive, but building one yourself from repurposed materials can be both cost-effective and efficient for smaller projects.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal brake for bending small work for those who prefer to do it yourself.

Learn how to create a homemade bending brake that can bend sheet metal up to 50cm in length or even tough materials like a circular saw blade! Plus, you will surely love the step-by-step details in the following instructional video.A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

sheet metal bending brake

At the moment its possible to Bend 750mm long and maximum of 1,5mm thick steel, shorter should be 2mm possible. To build it for 1m should be also possible. To turn the Bending (hold-down angle). Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and.Simple Sheet Metal Brake: No Welding: I love working with metal, but I've always struggled to get perfect 90° bends. Generally, I'll stick the piece to be bent in the vise and smack it around until it's bent.A metal brake is a machine used to bend sheet metal. Typically, it is composed of a stationary base, a clamping mechanism, and a movable component to build the bend. Commercial metal brakes can be expensive, but building one yourself from repurposed materials can be both cost-effective and efficient for smaller projects.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. This project will help you build a simple sheet metal brake for bending small work for those who prefer to do it yourself.

Learn how to create a homemade bending brake that can bend sheet metal up to 50cm in length or even tough materials like a circular saw blade! Plus, you will surely love the step-by-step details in the following instructional video.

how to bend galvanized steel

homemade sheet metal brake

homemade metal bender

home made sheet metal bender

Solar panel junction boxes play a crucial role in optimally performing and protecting photovoltaic (PV) systems. As a vital component of solar panels, junction boxes provide electrical connections, safeguard against environmental factors, and ensure efficient power conversion.

diy bend sheet metal|bending 16 gauge sheet metal