cnc machining nist The chemical mechanical planarization (CMP) process is a complex and critical operation in the semiconductor manufacturing industry, involving a wide variety of. Building a Digital Twin of a . Vintage Western Germany mark (late 1940s) metal biscuit tin or candy box made to look like a treasure chest, with a hasp to hold a little lock if you'd like to lock up your jewelry or other treasures! It measures 6 1/4" x 4 1/4" x 4 1/2" overall.

0 · Working with Precision: Tool Company Reduces Assembly Time

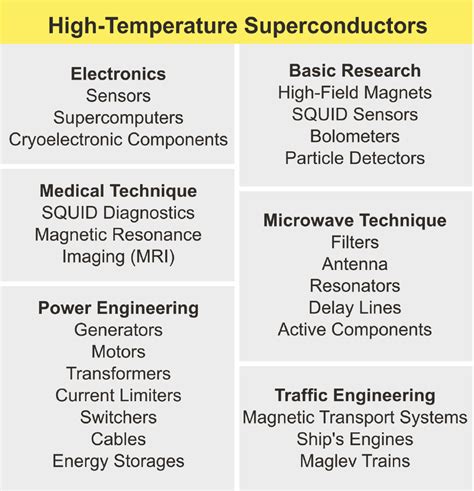

1 · The State of Integrated CAM/CNC Control Systems: Prior

2 · The Application of High

3 · TESTING STEP

4 · Standardization of Auxiliary Equipment for Next Generation CNC

5 · Standardization of Auxiliary Equipment for Next Generation

6 · On

7 · Machining

8 · Improving CNC Machining Accuracy Through Thermal Model

9 · Building a Digital Twin of a CNC Machine Tool

When splicing wires, an accessible electrical junction box box is necessary to enclose the spliced wires, thus the trade name is electrical enclosure. This list shows various electrical boxes and displays the box name and describes the typical application.

The chemical mechanical planarization (CMP) process is a complex and critical operation in the semiconductor manufacturing industry, involving a wide variety of. Building a Digital Twin of a .This paper presents the recent work of the Open Modular Architecture Control .This state-of-the-art review surveys existing methods for data transmission to and .This paper looks at the incorporation of Nominal Differential-Expansion as a .

Thorough and unambiguous definitions of a broad set of on-machine measurement .As a result of the conversion process, Timberline now produces 100% of its .In this paper, the application of high-speed machining to the production of . This paper presents the recent work of the Open Modular Architecture Control (OMAC) Machine Tool Working Group to support STEP-NC, which is a new standard for the .

This state-of-the-art review surveys existing methods for data transmission to and from machine tools and explores the current state of so-called integrated CAM/CNC systems .defines a data exchange standard for computerized numerical control machining (milling, turning, and electric discharge machining). STEP-NC will provide full product and process data . This paper looks at the incorporation of Nominal Differential-Expansion as a model based control strategy to improve the accuracy of a turning machine and part tolerance. .

Thorough and unambiguous definitions of a broad set of on-machine measurement use cases and information are offered. Relevant in-situ and off-machine measurement use cases are also . As a result of the conversion process, Timberline now produces 100% of its aluminum tools using the CNC machining process. In addition to the quality and strength . In this paper, the application of high-speed machining to the production of monolithic, metallic, functional prototypes is discussed and an example component with .

We will discuss results and related issues from the use of the STEP-NC and a CNC Virtual Machine that was done in an OMAC pilot project at Boeing and NIST to handle auxiliary . This paper uses a framework provided by the digital twin standard, ISO 23247, to build a digital twin of a Computer Numerical Control (CNC) machine tool. Software tools are . The literature survey reveals that integrated CAM/CNC systems are impeded both by the data exchange methods used to interface with CNC systems in addition to the proprietary and closed architecture of the CNC systems themselves. Future directions in integrated CAM/CNC research are identified based on the requirements identified for such systems.Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM

Working with Precision: Tool Company Reduces Assembly Time

Customizations of a machine tool CNC based on a procurement specification adds to the confusion. This disarray leads to productivity losses due to machine operation misunderstandings and programming confusion. The predominant Computer Numeric Control (CNC) machine tool programming language for over the last half century has been RS274.Gartom CNC provides custom and precision machining services to engineers, product developers, and designers. top of page. Home. About. Capabilities. Contact. More. Precision Machining. Get a Quote. Custom Machining. Prototyping & Fabrication .the manufacturer of the machine. The CNC machine uses G-Code (Geometric Code) and M-Code (Machine Code) depending on the machine in use. These codes can be transferred to the CNC machine in a variety of ways including, but not limited to: USB, Floppy Disk, and/or LAN connections. BACKGROUND INFORMATION C N C 3 CNC Machining SecurityTableofContents Acknowledgments i ExecutiveSummary ii ListofTables.. vii ListofFigures viii 1.Introduction 1 1.1TheDiscrete-PartIndustry 1 1.2TheMachineToolIndustry 2 1.3Machining 4 1.4Precision 5 1.5PrecisionandCompetitiveness 6 1.6PrecisionandMetrology 6 1.7PrecisionandCost 6 2.KeyChallengestotheDiscrete-PartandMachineToolIndustries 9 .

Large capacity CNC machining up to 9.5 ft vertical x 30 ft horizontal, and small capacity CNC machining with various size machines and up to 20,000 RPM. Our versatile CNC machine production systems allow us to produce a variety of 1pc samples to thousands of parts per month.

Some CNC machine shop leaders have had an education in Bitcoin digital currency, but for the wrong reason: They have been forced to pay ransom online for sensitive data that had essentially been held hostage by hackers. . Level 3 (“good” cyber hygiene) covers 130 different cybersecurity practices (including all of NIST 800-171, plus 20 .

Security is more of a concern than ever. If you’re researching CNC machine shops, those that are ITAR registered signifies that the machine shop has established strong security measures such as NIST 800-171 (nist.gov) to safeguard your sensitive technical data and proprietary information. In the metal cutting industry, measurement of machining performance is usually carried out by collecting machine monitoring data that record the machine tool s actions (e.g., coordinates of axis location and power consumption). Understanding the impacts of process planning decisions is central to the enhancement of the machining performance.

What started out of a garage as a two-person business has grown into an established company with nearly 50 employees that specializes in the manufacture of machined components using high precision CNC equipment: vertical machining centers, horizontal machining centers with pallet systems and multi-axis lathes with live tooling.Our 12,000 square foot CNC machine shop specializes in high demand industries. Precision Tool is a leader in rapid prototyping, short-run and high-volume machining projects. . Compliant with DFARS and NIST 800-171. Specialized & Experienced Industries We Service. Equipped to design, manufacture or repair to meet the demands of the following .

Hampton Roads, VA. located machine shop and prototyping services provider. 5-Axis CNC Mill, Sheet Metal Processing, Fabrication, Design and Testing services.

[email protected] . ABSTRACT . As a foundation of digital transformation, digital twins are critical for achieving smart manufacturing. Recent technology . and increased throughput. or a CNC machining For instance, f process, real-time data from sensors on the machine and cutting tools can be collected and provided to the digital twin. The digital

Based on energy monitoring during two Computer Numerical Control (CNC) machining case studies, the significance of energy cost based on different CNC machining strategies and parameter settings is examined and discussed. . If you have any questions about this publication or are having problems accessing it, please contact [email protected] .Toolcraft ensures high quality with every CNC precision machining project with a CMM parts inspection and an ISO 9001 CNC Certification. Your Industries. Mining; . Toolcraft Machining is currently compliant with NIST 800 - 171 and actively working towards Cybersecurity Maturity Model Certification (CMMC). This represents our commitment to . The National Institute of Standards and Technology (NIST) provides guidelines, specifically NIST 800-171, which are essential for defence contractors. These standards ensure that manufacturing processes, including CNC machining, are protected from cyber threats, safeguarding intellectual property and operational integrity.

Bedford Machine & Tool’s horizontal & vertical milling capacity covers a full range of requirements for large manufacturing needs. If you need a large project completed, you can count on our team of professionals at Bedford Machine to get the job done. Bedford Machine & Tool has been doing large part CNC machining for over 30 years. ATN developed and delivered a custom 68-hour CNC Machinist Training Curriculum. Each training module was geared to increase overall knowledge of machining concepts by providing a broader understanding in the areas of precision measurement, shop math, tooling, blueprint reading and machine operation.

On the shop floor, the machining stage uses a machine tool to cut a metal casting or raw stock to create the “Part.” A CNC computer d irects the machining operations. The machining stage employs a CNC machine tool with sufficient accuracy and precision to meet part tolerances and associates the necessary raw stock or castedCMMC NIST SP 800-171 ENDLESS POSSIBILITIES Our 75,000 square foot state-of-the-art facility is equipped with cutting-edge resources and the latest CNC manufacturing technologies. . Welcome to TKO Precision Machining, your specialist in precision CNC machining for diverse industries including Aerospace, Defense, Medical Equipment, Power .the manufacturer of the machine. The CNC machine uses G-Code (Geometric Code) and M-Code (Machine Code) depending on the machine in use. These codes can be transferred to the CNC machine in a variety of ways including, but not limited to: USB, Floppy Disk, and/or LAN connections. BACKGROUND INFORMATION C N C 3 CNC Machining Security Current Industrial Practice: CAM to G-Code to CNC CAM systems create G-Code using post processors – Machine specific instructions G-Code: text-based NC programming language, originally standardized in 1960s, still dominant today – Serial execution – Lines, arcs, and splines (primitives) – Maximum traversal velocity Industrial CNC systems

ing the Okuma CNC with OPC Server in actual production at Boeing [7]. Next, NIST developed a Scrap Monitoring OPC client application written in Visual C++ that ran on the Okuma CNC. We used OPC data access to automatically monitor themachiningofparts. Todeterminescrap,weonlyneeded a few OPC tags, which the Okuma OPC server provided.

CNC Machining Capabilities. AMG Engineering & Machining, Incorporated, is a AS9100D, IATF 16949, and ISO9001:2015 certified machining and manufacturing operation. Our focus comprises medium diameter (.050″ to 28″ turned and 2″ to 40″) milled parts with lengths up to 70″. All NIST SP 800-171 controls as well as the objective statements of NIST SP 800-171a. Storage for policies and evidence. Linkage between controls and objectives to the policies and evidence files. . An out-of-scope asset could be a CNC machine, assembly robot or other such asset. The easiest way to narrow down the scope is to ensure the types .

cnc sheet metal processing factories

The State of Integrated CAM/CNC Control Systems: Prior

David Jones Elizabeth Street and Market St Sydney stores will open at 5am on Boxing Day, with the official bell ringing at Elizabeth St. Westfield Bondi Junction. Boxing Day 7am — 9pm

cnc machining nist|Standardization of Auxiliary Equipment for Next Generation