joggling process in sheet metal Common forms of sheet metal bending include bottoming, air bending, coining, wiping, folding, rolling, and joggling. Bottoming “Bottoming” refers to a press brake process where the machine presses the workpiece, a section of sheet metal, all the way to the bottom of the die, so the workpiece touches the edges of the V or U shape of the die. Stainless steel lunch boxes are being purchased and used by more and more households because they are beautiful, easy to clean, corrosion resistant and durable. As a stainless steel lunch box manufacturer, we have been designing students and adults’ lunch boxes with over 20 years of experience.

0 · shrinking sheet metal by hand

1 · sheet metal joggle tool

2 · open hem sheet metal

3 · lightening holes in sheet metal

4 · hand forming aluminum sheet metal

5 · forming sheet metal by hand

6 · forming joggles in sheet metal

7 · forming aluminum sheet by hand

$6.64

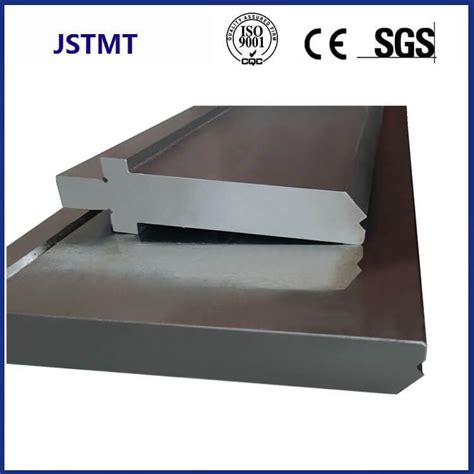

A joggle in sheet metal is a small offset or bend to create an overlapping joint on a flush surface. The offset bending process creates two opposite bends with equal angles in a single action. The joggle bends are in .An Introduction Stretch forming is a metal forming process that simultaneously stretches and bends a selected material over a machined form, called a die, to form a part with one or several different curve radii. This process produces .Common forms of sheet metal bending include bottoming, air bending, coining, wiping, folding, rolling, and joggling. Bottoming “Bottoming” refers to a press brake process where the machine presses the workpiece, a section of sheet metal, all the way to the bottom of the die, so the workpiece touches the edges of the V or U shape of the die.

Joggling or segmented bending is shaping a sheet metal section by section using stringers and formers. The technique is especially helpful when there is a need to bend an extended workpiece in a periodically repeated .

Joggling. Joggling is a process where a machine bends the metal in both directions creating an ‘S’ or ‘Z’ shape. . Rotary bending is a complex process of sheet metal bending. The process tends to create pipes, which can offer a variety of central line radiuses. The process involves bending a tube with a mandrel inserted inside so that . Therefore, choosing a suitable material is paramount before starting any aerospace sheet metal fabrication process. Today, some popular materials you can use in the industry include: Stainless steel like the SS 17-4 PH; Titanium such as the Ti-6Al-4V; Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste. . Joggling Sheet Metal. Joggling is a specific .

Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste. . Applications of Joggling in Sheet Metal . Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. . BMC Press, Labrotaroy press, edge cutting trimming machine, edge curling machine, trimming beading machine, trimming joggling machine, cookware production line, pipe bending machine, profile .Sheet Metal Fabrication: Trimming joggling machines are used in sheet metal fabrication to trim and form the edges of various components, such as flanges, enclosures, and ducting. Automotive Industry: . Process: The sheet metal is placed under a forming tool or die, and the machine applies force to create the desired offset or flange. The . Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste. . Applications of Joggling in Sheet Metal .

Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste. . Applications of Joggling in Sheet Metal .

shrinking sheet metal by hand

the joggling process. fastening steel parts. 4 of 49. Definition. fastening steel parts. mild steel rivets are used for. . the most commonly used holder in sheet metal would be the? Choose matching definition. black. bench clamp. cleco. dimple. Don't know? 16 of 49. Term. rivnuts were initially used for? Choose matching definition.Sheet Forming: A manufacturing process where metal sheets are shaped by applying force, often using presses, into desired forms such as panels, enclosures, or structural components. Pascal’s Law: A principle in fluid mechanics stating that pressure applied to a confined fluid is transmitted undiminished in all directions.

why no hidden junction boxes

Deep Drawing: Deep drawing is a process where a sheet of metal is stretched into a desired shape, typically for components like metal cans or kitchen sinks. Automated systems handle the positioning of the blank and the control of the punch, ensuring repeatability and minimizing material waste. . Applications of Joggling in Sheet Metal . Deep Drawing Process in Sheet Metal. Deep Drawing Process in Sheet Metal: The deep drawing process is a critical metal forming technique used across various industries, from automotive to aerospace, for producing high-quality, precision metal parts.A central element in the success of the deep drawing process is the hydraulic press, a versatile and highly controlled .A metal forming process in which a flat piece of plate or sheet is drawn radically into a forming die by the mechanical action of a punch, to take a shape such as a cup. This process is considered deep drawing when the intensity of the drawn .

The sheet metal fabrication process produces the metal parts by using various techniques that alter the shape of the flat sheet metal to the required structure. Let's dive into the post to absorb more details. . Joggling involves creating offset bends or flanges in metal sheets in order to simplify the joining or assembly of assemblies like . Sheet Metal Joggle Tool: Metal forming is a critical process in manufacturing that involves shaping metal materials into desired forms by applying force. This process transforms raw metal materials, such as sheets, rods, or bars, into components used in various industries, including automotive, aerospace, construction, and electronics.Hemming 24 gauge materialwww.cscmachine.com

sheet metal joggle tool

8. Curling in Sheet Metal. Process Overview: Curling in sheet metal involves rolling the edge of a metal sheet into a curved shape, typically to create a safe, finished edge. This process is vital for products like lids and containers, where a smooth, strong edge is necessary. In this video Pete will demonstrate a technique for creating a flange overlap feature, or a jog feature, that can be very useful for fastening large sheet me.

Hot Joggling Aluminum. Roll Forming. Extrusion Stretch Forming. Sheet Metal Stretch Forming “Blue Streak” Forming Process. Equipment. Verson Deep Draw Press. 400 ton, 60” x 119”, 200 ton cushon. CNC Brake Press. 90 ton, 120”, 7-axis. Titanium Hot Form Press X2.If you were installing a repair sheet and you needed to make a step up at an angle, what would the process be called? Joggling It was reported that a 737-800 series aircraft was found to have a fuselage skin gauge that had a crack.

Trimming Joggling Machine; Base Grooving Machine; Circle cutting machine; Heavy Duty Adjustable Circle Cutter for Metal; . Deep drawing is a sheet metal forming process in which a flat metal blank is radially drawn into a forming die by the mechanical action of a punch. The process can produce parts with a depth greater than their diameter .

The joggling process. The specific details of the joggling process can vary depending on the type of part being fabricated and the industry requirements. However, we can provide a general overview of the steps involved in joggling. 1) A previously spun metal spinning (dished end) is placed on the joggler and clamped.

open hem sheet metal

why do old boxes of steel nails sometimes become magnetized

wide 1 gang metal box

Precision sheet metal fabrication for a single part, batch of prototypes or full production order. 50+ Materials. Free US Shipping. 100% Quality Guaranteed.

joggling process in sheet metal|forming sheet metal by hand