6 axis cnc machine cost These machines cost anywhere from $200,000 and up, although many are over $500,000. 6-axis machines and larger industrial machining centers can be $250,000 to $500,000, as well. Note that used CNC machines may have a lower price tag, but they may be more prone to breakdowns, require replacement parts, and are limited to smaller-scale . Junction boxes are used to connect cables to add socket, lighting points, extend circuits etc. They can also be used to make repairs where a section of cable needs to be replaced. Junction boxes can be found as either round or square boxes, round ones are more common, square ones tend to be used for higher current cables.

0 · what is 6 axis machining

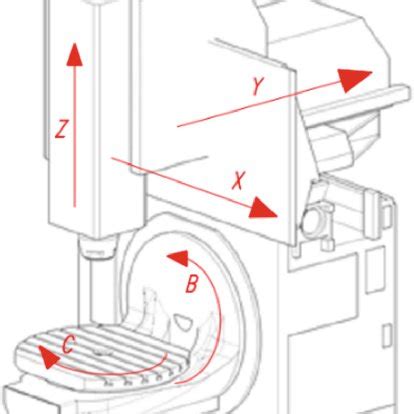

1 · haas 6 axis cnc

2 · cnc machine axis locations diagram

3 · cnc machine axis identification

4 · 6 axis milling machine

5 · 6 axis machining center

6 · 6 axis cnc milling machine

7 · 6 axis cnc machine price

Sheet metal welding is the process through which a thin sheet of metal is welded to another sheet or metal component. It is mostly used in the fabrication of structural elements and gadgets, including ventilation ducts and other sheet metal parts. How to weld sheet metal?

These machines cost anywhere from 0,000 and up, although many are over 0,000. 6-axis machines and larger industrial machining centers can be 0,000 to 0,000, as well. Note that used CNC machines may have a .The cost of a 6-axis CNC machine is influenced by various factors that determine its value and functionalities. In this section, we will discuss these factors in detail, including machine size, .These machines cost anywhere from 0,000 and up, although many are over 0,000. 6-axis machines and larger industrial machining centers can be 0,000 to 0,000, as well. Note that used CNC machines may have a lower price tag, but they may be more prone to breakdowns, require replacement parts, and are limited to smaller-scale .

The cost of a 6-axis CNC machine is influenced by various factors that determine its value and functionalities. In this section, we will discuss these factors in detail, including machine size, type, brand, configuration, additional features, and the level of automation.

How Much do 6 Axis CNC Routers Cost? What is a 6 Axis CNC Router? Every CNC router, mill, and lathe use axes which are essential to the manufacturing process. This is because the axes determine how both the tools and workpieces move during production.The price of a 6-axis CNC milling machine can vary greatly, depending on several factors. On the lower end, you can expect a basic machine to cost around ,000. On the high end, prices can reach up to 0,000 or more. A hobbyist CNC like the Sainsmart Genmitsu CNC has its stepper motor torque running at 0.18 ft-lb, while a professional 6-axis CNC like the Zimmerman FZ100 can generate a torque of 68 ft-lb. That’s almost 400 times more.

The most expensive CNC machines are the 6-axis and 5-axis robotic CNCs that are used in manufacturing high-end military equipment and cost in the excess of millions of dollars. On the other hand, there are very affordable CNC machines that can be used by entry-level hobbyists that cost as low as 0. A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, the power and torque, number of axes, and many other factors. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area). Types of CNC Machines / Configuration (3, 4, or 5 axis cnc mills vs 2 axis or more lathe)From their toolroom mills and lathes to their small production machines, you can expect to find entry level CNCs starting at about the k range.

Search for used cnc milling machine 6 axis. Find Mazak, Mori Seiki, Okuma, Bridgeport, Milltronics, Kent, Hardinge, Hyundai, and TRAK for sale on Machinio.

what is 6 axis machining

These machines cost anywhere from 0,000 and up, although many are over 0,000. 6-axis machines and larger industrial machining centers can be 0,000 to 0,000, as well. Note that used CNC machines may have a lower price tag, but they may be more prone to breakdowns, require replacement parts, and are limited to smaller-scale .The cost of a 6-axis CNC machine is influenced by various factors that determine its value and functionalities. In this section, we will discuss these factors in detail, including machine size, type, brand, configuration, additional features, and the level of automation.

steel bike pannier box

How Much do 6 Axis CNC Routers Cost? What is a 6 Axis CNC Router? Every CNC router, mill, and lathe use axes which are essential to the manufacturing process. This is because the axes determine how both the tools and workpieces move during production.The price of a 6-axis CNC milling machine can vary greatly, depending on several factors. On the lower end, you can expect a basic machine to cost around ,000. On the high end, prices can reach up to 0,000 or more. A hobbyist CNC like the Sainsmart Genmitsu CNC has its stepper motor torque running at 0.18 ft-lb, while a professional 6-axis CNC like the Zimmerman FZ100 can generate a torque of 68 ft-lb. That’s almost 400 times more.

The most expensive CNC machines are the 6-axis and 5-axis robotic CNCs that are used in manufacturing high-end military equipment and cost in the excess of millions of dollars. On the other hand, there are very affordable CNC machines that can be used by entry-level hobbyists that cost as low as 0. A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, the power and torque, number of axes, and many other factors. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area). Types of CNC Machines / Configuration (3, 4, or 5 axis cnc mills vs 2 axis or more lathe)

haas 6 axis cnc

From their toolroom mills and lathes to their small production machines, you can expect to find entry level CNCs starting at about the k range.

cnc machine axis locations diagram

steel bar cabinet hardware pull

steel as cylinders box wheels

So, what drill bit is ideal for a 6 screw? The answer is simple – use a #6 screwdriver bit. This size screwdriver bit fits most screws that are used in household projects. It will fit the screws on your furniture, as well as any .

6 axis cnc machine cost|what is 6 axis machining