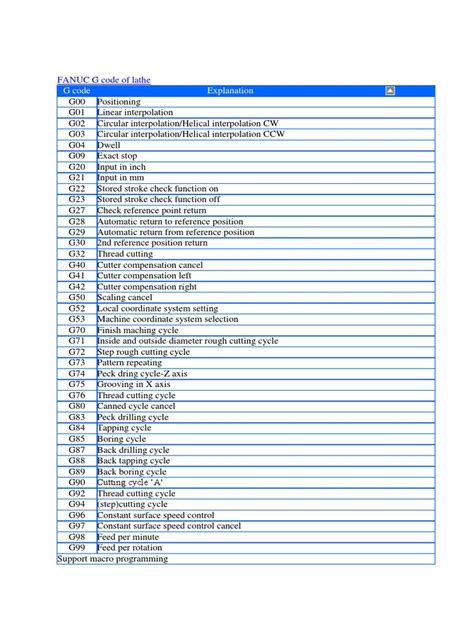

cnc machine g code list CNC G-codes & M Codes for milling and turning with explanations, . $8.91

0 · list of fanuc g codes

1 · list of all g codes

2 · g code table listing

3 · g code reference chart

4 · g code for cnc milling

5 · complete g code list

6 · cnc turning g code list

7 · cnc milling g codes list

Model : UF340/25BB 340 x 340 x 25mm Underground Floor Service Outlet Box (Junction Box) Brand : Davis Type : 340 x 340 x 25mm, 3 Compartment Underfloor Service Box (Junction Box) Color : Fair Grey Weight : 5.9kg Product Size (cm) : 34 .

old telephone junction box

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. CNC G-codes & M Codes for milling and turning with explanations, .

ANILAM G Code List for CNC Mill Controls like 6000M G-codes . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

old style bt junction box

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M . A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or . Here is a list of common G codes. Take note that although most G codes are universal, these specific G codes are what you will find on a Haas machine, and your specific . Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)Complete G-Code list for Hust Lathe CNC Controllers. A good reference for CNC machinists who work on CNC Lathe with Hust CNC controls. Following G code list works on following.

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw . Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc.

Check out the list of G-codes in CNC machining. G00 – Rapid positioning. Format: G00 x (U)__ Z (W)__ Explain: (1) The command makes the tool move to the designated position quickly according to the point control mode. The workpiece shall not be machined during moving. A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or presets the control system to use a certain mode or operation. Below is the list of G-codes that are used in most modern CNC Milling machines:

List of common CNC G codes and their meanings.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)Complete G-Code list for Hust Lathe CNC Controllers. A good reference for CNC machinists who work on CNC Lathe with Hust CNC controls. Following G code list works on following. Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin. This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc.

Check out the list of G-codes in CNC machining. G00 – Rapid positioning. Format: G00 x (U)__ Z (W)__ Explain: (1) The command makes the tool move to the designated position quickly according to the point control mode. The workpiece shall not be machined during moving. A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or presets the control system to use a certain mode or operation. Below is the list of G-codes that are used in most modern CNC Milling machines:

list of fanuc g codes

list of all g codes

g code table listing

The two main materials for the under-the-cabinet and space-saving coffee makers are stainless steel and plastic. Both are hygienic, have good thermal conductivity, and are easy to clean. Pay close attention to build quality, design, and durability when choosing a coffee maker.

cnc machine g code list|cnc turning g code list