electrical box clearance The site is secure. The https:// ensures that you are connecting to the official website . The Sigma ProConnex Clamp Type Cable Connectors are used to terminate NM Cable or Flexible Cord to a 1/2-in knockout in a dry location box or enclosure. These die-cast zinc connectors feature a reversible locknut to preserve grounding.

0 · working clearance for electrical panel

1 · residential electrical panel clearance requirements

2 · osha electrical panel clearance requirements

3 · nec electrical panel clearance requirements

4 · electrical panel clearances

5 · electrical panel clearance requirements

6 · clearances around electrical panels

7 · clearance required around electrical panel

Three-way switch wiring diagram with the LINE and the LOAD inside separate switch boxes. LINE power is delivered to the first switch by using a two conductor cable with a bare or green equipment grounding conductor. The LINE wire is connected to the "Common" terminal on the 3-way switch.

Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;The site is secure. The https:// ensures that you are connecting to the official website .The site is secure. The https:// ensures that you are connecting to the official website . In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36’’ of clearance around it. Panels with 151 to 600 volts should have 42’’ of .

Learn how to install or upgrade an electrical panel safely and efficiently by following the working clearance requirements in the 2021 International Residential Code. Find out the minimum dimensions, prohibited locations, and other tips .

For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with . Requirements for working clearances and spaces around electrical equipment, e.g., ladder cable trays. OSHA requirements are set by statute, standards and regulations. Our .

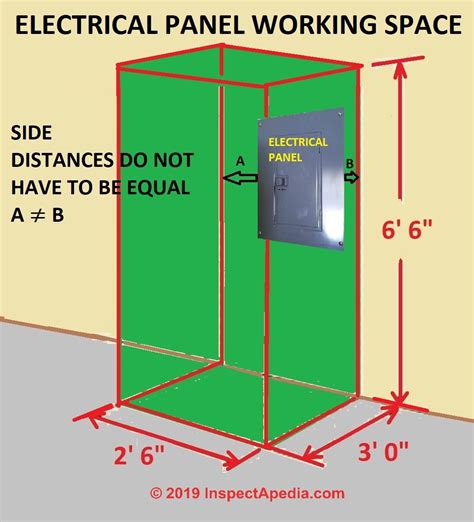

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions .Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements. In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36’’ of clearance around it. Panels with 151 to 600 volts should have 42’’ of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.

working clearance for electrical panel

Specifically Section E3405 outlines proper panel location and minimum clearances that are to be maintained in residential structures subject to the IRC. What Are the Working Clearance Requirements Around an Electrical Panel?For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment. Requirements for working clearances and spaces around electrical equipment, e.g., ladder cable trays. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations.

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.Working space: The front clearance, side clearance, and height clearance requirements for electrical equipment that provide a safe area for maintenance, inspections, and other work.Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident. An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.

Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.

In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36’’ of clearance around it. Panels with 151 to 600 volts should have 42’’ of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.Specifically Section E3405 outlines proper panel location and minimum clearances that are to be maintained in residential structures subject to the IRC. What Are the Working Clearance Requirements Around an Electrical Panel?

metal fire box severely deterioated

For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment. Requirements for working clearances and spaces around electrical equipment, e.g., ladder cable trays. OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations.OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.

metal fabricators yakima yakima wa

Working space: The front clearance, side clearance, and height clearance requirements for electrical equipment that provide a safe area for maintenance, inspections, and other work.Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident.

residential electrical panel clearance requirements

osha electrical panel clearance requirements

Inspired by the endangered bengal tigers at the famous Kanha Tiger Perserve in India, this amazing animal operates with a windup tin toy engine. Just place the metal key in the jungle .

electrical box clearance|clearance required around electrical panel