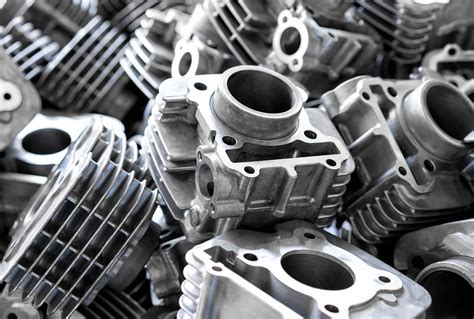

cnc die casting machine CNC Machining and Die casting are two of the most common industrial manufacturing methods. But which is better? Here is a comprehensive CNC Vs. Die Casting points to understand the most suitable one for your project. Installing a dishwasher junction box is an essential step in completing a successful dishwasher installation. This guide will provide you with a comprehensive walkthrough of the process, ensuring a secure and functional connection for your Bosch dishwasher.

0 · metals used in die casting

1 · materials used in die casting

2 · high pressure die casting machines

3 · high pressure casting machine

4 · die casting machines for sale

5 · die casting machine price

6 · die casting machine hydraulic system

7 · die casting machine cost

Pull boxes are used in conduit lines when outlet bends exceed the National Electric Code’s maximum number. The specific size of the pull box depends on the size and the number of conductors. In addition, the diameter and the quantity of the raceway also determined the size of .

metals used in die casting

CNC Machining and Die casting are two of the most common industrial manufacturing methods. But which is better? Here is a comprehensive CNC Vs. Die Casting points to understand the most suitable one for your project. Shibaura Machine (FKA Toshiba Machine) is a leading global manufacturer of precision injection molding machines, machine tools, & die casting machines. Call us!

Die casting is fast and excellent for producing highly accurate and repeatable parts. Die-cast parts are stronger than their plastic counterparts, have smooth surface finishes, and are relatively durable. Additionally, die casting .

hickey metal fabrication ohio

The hot chamber die casting machine operates on the principle of injecting molten metal into a closed hot chamber, heating it to a specific temperature using a heating system, and then . CNC (Computer Numerical Control) machining is a subtractive process where material is removed to create parts. It’s renowned for its precision and flexibility, capable of producing complex designs with high accuracy. Die . For a given project, you can choose between CNC machining and die casting depending on what will suit the project best. If you require high precision parts, low volumes, . Die casting is used to cast the main body of the part to avoid material waste, then the details are left to CNC machining for higher precision. So the best way for you to know the exact manufacturing cost is to get a quote.

CNC Machining and Die casting are two of the most common industrial manufacturing methods. But which is better? Here is a comprehensive CNC Vs. Die Casting points to understand the most suitable one for your project. Shibaura Machine (FKA Toshiba Machine) is a leading global manufacturer of precision injection molding machines, machine tools, & die casting machines. Call us!

Die casting is fast and excellent for producing highly accurate and repeatable parts. Die-cast parts are stronger than their plastic counterparts, have smooth surface finishes, and are relatively durable. Additionally, die casting edges out CNC machining when it comes to high-volume production runs and manufacturing products at scale.The hot chamber die casting machine operates on the principle of injecting molten metal into a closed hot chamber, heating it to a specific temperature using a heating system, and then using high pressure to inject the metal into the mold to form a variety of product shapes.

Learn the difference between casting and CNC machining and check out our tips for when to choose each process. Read now! CNC (Computer Numerical Control) machining is a subtractive process where material is removed to create parts. It’s renowned for its precision and flexibility, capable of producing complex designs with high accuracy. Die casting, on the other hand, is a formative process. It involves forcing molten metal under high pressure into mold cavities. For a given project, you can choose between CNC machining and die casting depending on what will suit the project best. If you require high precision parts, low volumes, or require materials that cannot be used in die casting. So, you can opt for CNC machining as it is suitable for use. Die casting is used to cast the main body of the part to avoid material waste, then the details are left to CNC machining for higher precision. So the best way for you to know the exact manufacturing cost is to get a quote.

You can use machining on a die casting part to create tighter tolerances or create features on the part that cannot be die cast, and you can even use machining to make the die itself that will be used for the die casting process. One advantage of using CNC machining is that it is better for low volume parts since no tooling cost is required . Die casting excels in producing high-volume parts with intricate details and minimal post-processing, making it cost-effective for mass production. On the other hand, machining offers versatility, precision, and flexibility, making it suitable for custom or low-volume production runs and complex geometries.

CNC Machining and Die casting are two of the most common industrial manufacturing methods. But which is better? Here is a comprehensive CNC Vs. Die Casting points to understand the most suitable one for your project.

Shibaura Machine (FKA Toshiba Machine) is a leading global manufacturer of precision injection molding machines, machine tools, & die casting machines. Call us!

Die casting is fast and excellent for producing highly accurate and repeatable parts. Die-cast parts are stronger than their plastic counterparts, have smooth surface finishes, and are relatively durable. Additionally, die casting edges out CNC machining when it comes to high-volume production runs and manufacturing products at scale.The hot chamber die casting machine operates on the principle of injecting molten metal into a closed hot chamber, heating it to a specific temperature using a heating system, and then using high pressure to inject the metal into the mold to form a variety of product shapes.Learn the difference between casting and CNC machining and check out our tips for when to choose each process. Read now! CNC (Computer Numerical Control) machining is a subtractive process where material is removed to create parts. It’s renowned for its precision and flexibility, capable of producing complex designs with high accuracy. Die casting, on the other hand, is a formative process. It involves forcing molten metal under high pressure into mold cavities.

For a given project, you can choose between CNC machining and die casting depending on what will suit the project best. If you require high precision parts, low volumes, or require materials that cannot be used in die casting. So, you can opt for CNC machining as it is suitable for use. Die casting is used to cast the main body of the part to avoid material waste, then the details are left to CNC machining for higher precision. So the best way for you to know the exact manufacturing cost is to get a quote.You can use machining on a die casting part to create tighter tolerances or create features on the part that cannot be die cast, and you can even use machining to make the die itself that will be used for the die casting process. One advantage of using CNC machining is that it is better for low volume parts since no tooling cost is required .

hickey metal fabrication

Home-it stainless steel bread box has a very sleek design which imparts a modern look to the kitchen. The box is made of polished stainless steel and has rounded corners. The swing door mechanism makes it easy to put breads in the box and take them out. The door closes to form a tight seal which does not allow moisture to damage the breads.

cnc die casting machine|die casting machine price