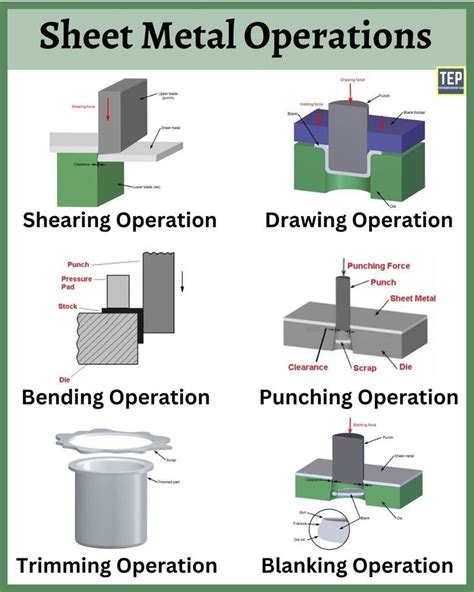

diagram showing the fabrication process of sheet metal repair Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly . Transparent aluminum, also known as aluminum oxynitride, is a transparent polycrystalline ceramic with a cubic spinel crystal structure made of nitrogen, oxygen and aluminum. It is optically transparent in the near-ultraviolet, visible and infrared regions.

0 · sheet metal process

1 · sheet metal operations pdf

2 · sheet metal operations diagram

3 · sheet metal fabrication services

4 · sheet metal fabrication process

5 · sheet metal drawing operations

6 · metal fabrication processes

7 · material fabricating process

The SL807 from ESR is a Standard 35mm Single Gang Surface Patress Box ideal for mounting any switches or sockets with a 35mm or lower minimum recessed depth. This box is constructed from high quality, durable scratch resistant thermoplastic, and features a simple and reliable design with round edges.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .

Steps in the Metal Fabrication Process; Benefits of Precision Sheet Metal Fabrication; Quality Assurance & Testing in Custom Sheet Metal Fabricating; Metal Fabrication Services by H&S . Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing .In this step-by-step guide, we’ll take you through the main processes of sheet metal fabrication, including designing the product, as well as cutting, welding, bending & forming, and finishing the metal.

Sheet metal fabrication refers to processes for transforming flat raw metal stock into customized, formed parts with desired shapes and dimensions. It encompasses a variety of techniques, machinery and workflows for bending, .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication .

sheet metal process

Sheet metal fabrication is the process of transforming flat metal sheets into custom components used in various industries. This process involves cutting, bending, forming, and joining techniques to create products such as . In this blog, we explore the process of sheet metal fabrication and the various techniques involved. This includes heating, bending, notching, shrinking, and beading. We’ll delve into each step to give you a .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals.

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .Steps in the Metal Fabrication Process; Benefits of Precision Sheet Metal Fabrication; Quality Assurance & Testing in Custom Sheet Metal Fabricating; Metal Fabrication Services by H&S Manufacturing CompanySheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar.

In this step-by-step guide, we’ll take you through the main processes of sheet metal fabrication, including designing the product, as well as cutting, welding, bending & forming, and finishing the metal.

Sheet metal fabrication refers to processes for transforming flat raw metal stock into customized, formed parts with desired shapes and dimensions. It encompasses a variety of techniques, machinery and workflows for bending, cutting, and assembling metal.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. How does sheet metal fabrication work? Sheet metal fabrication is the process of transforming flat metal sheets into custom components used in various industries. This process involves cutting, bending, forming, and joining techniques to create products such as brackets and enclosures. In this blog, we explore the process of sheet metal fabrication and the various techniques involved. This includes heating, bending, notching, shrinking, and beading. We’ll delve into each step to give you a comprehensive understanding of how these methods contribute to successful sheet metal work.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

Steps in the Metal Fabrication Process; Benefits of Precision Sheet Metal Fabrication; Quality Assurance & Testing in Custom Sheet Metal Fabricating; Metal Fabrication Services by H&S Manufacturing CompanySheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar.In this step-by-step guide, we’ll take you through the main processes of sheet metal fabrication, including designing the product, as well as cutting, welding, bending & forming, and finishing the metal.

Sheet metal fabrication refers to processes for transforming flat raw metal stock into customized, formed parts with desired shapes and dimensions. It encompasses a variety of techniques, machinery and workflows for bending, cutting, and assembling metal.

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. How does sheet metal fabrication work? Sheet metal fabrication is the process of transforming flat metal sheets into custom components used in various industries. This process involves cutting, bending, forming, and joining techniques to create products such as brackets and enclosures.

sheet metal operations pdf

Tree mount junction box for landscape lighting. Aluminum box with tree-safe stainless steel mounting screws two 1/2 inch NPT threaded holes.

diagram showing the fabrication process of sheet metal repair|sheet metal process